N-shaped univolume diaphragm collecting-winding lamination stacking machine and lamination stacking method

A technology of single-roll diaphragm and stacking machine, applied in the direction of sustainable manufacturing/processing, climate sustainability, non-aqueous electrolyte battery, etc., can solve the problems of high price, waste of diaphragm, inconvenient operation, etc., and achieve good quality and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

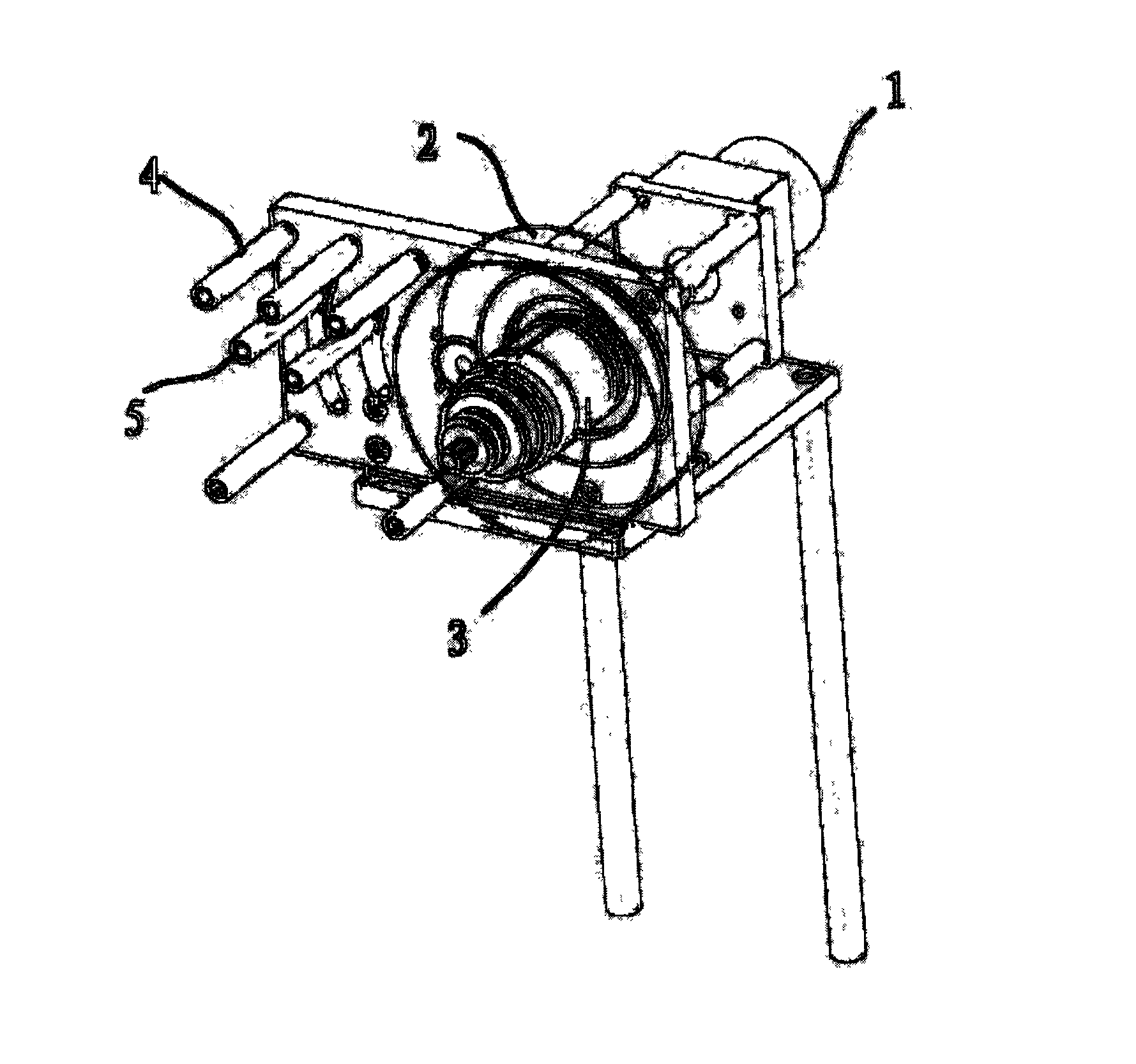

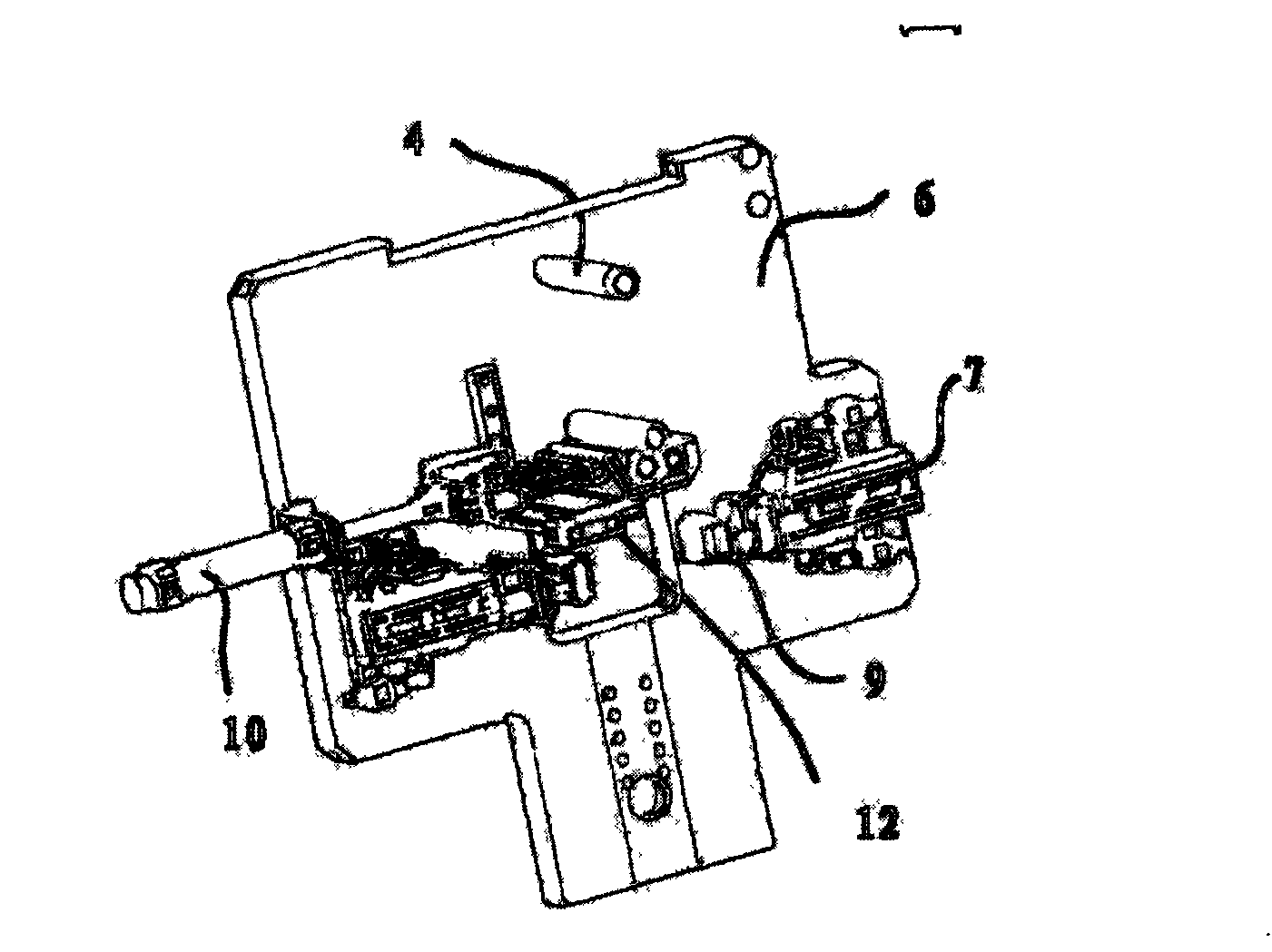

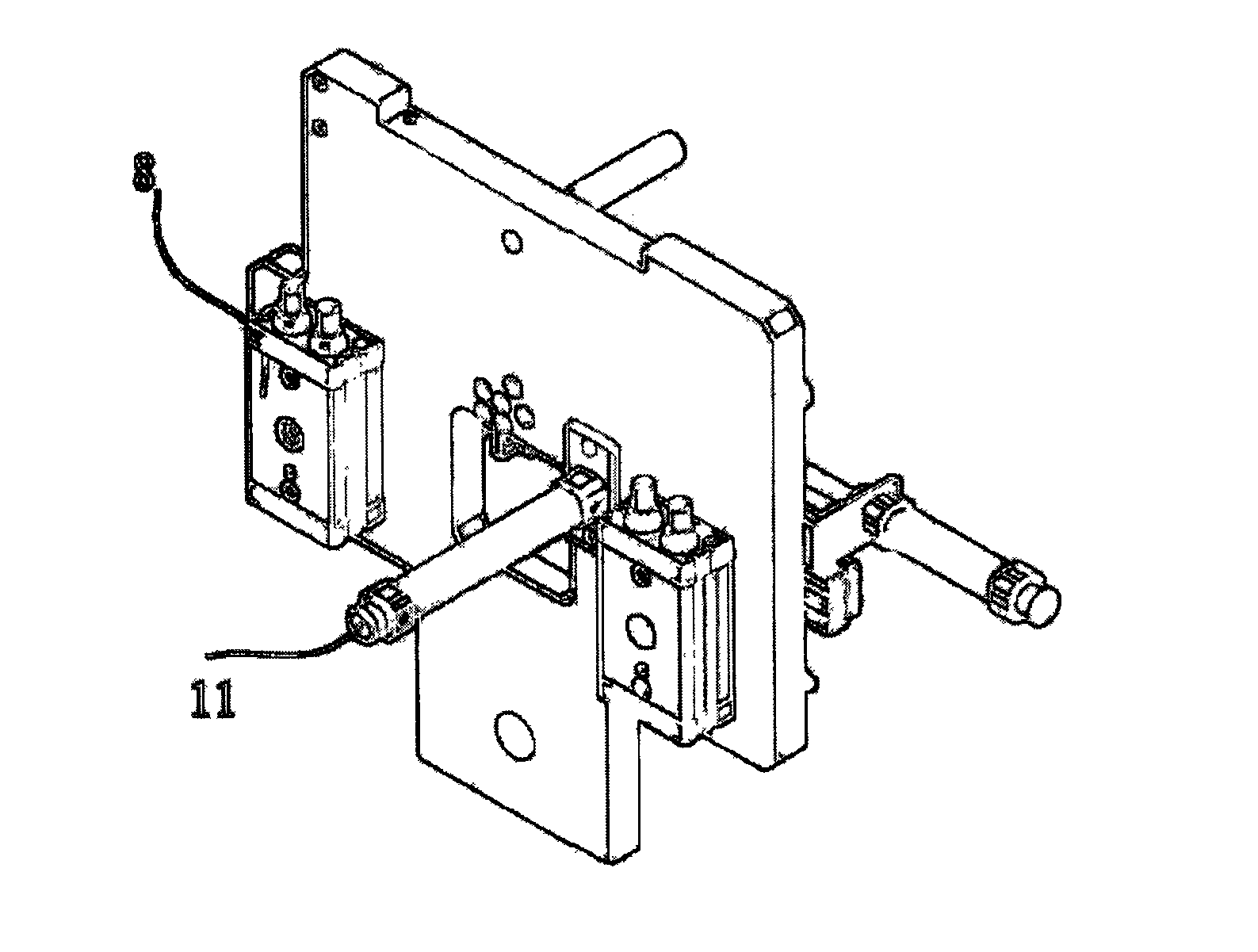

[0074] The present invention includes diaphragm unwinding buffer unit 001 ( Figure 1 ), 90-degree rotating suction sheet lamination unit 002 ( Figure 2A -B), pole piece clamping 180 degrees positive / reverse reciprocating rotation unit 003 ( Figure 3A -B), Diaphragm pulling buffer rewinding unit 004 ( Figure 4A -B), positive / negative plate positioning feeding unit 005 ( Figure five ), magazine storage unit 006 (see Figure six ), the top unit 007 on the pole piece of the material box (see Figure six ), retrieving unit 008 ( Figure seven ) and the large carrier board (code 18) on which all devices are installed.

[0075] Further, the diaphragm unwinding buffer unit 001 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com