Surface acoustic wave (SAW) harmonic oscillator system used for gas sensor

A gas sensor and oscillator technology, applied in electrical components, impedance networks, etc., can solve problems such as affecting the stability and service life of oscillators, increasing the difficulty of device fabrication, and increasing device fabrication costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] For a fuller understanding of the invention, with additional objects and advantages thereof, reference should now be made to the following detailed description of the invention taken in conjunction with the accompanying drawings.

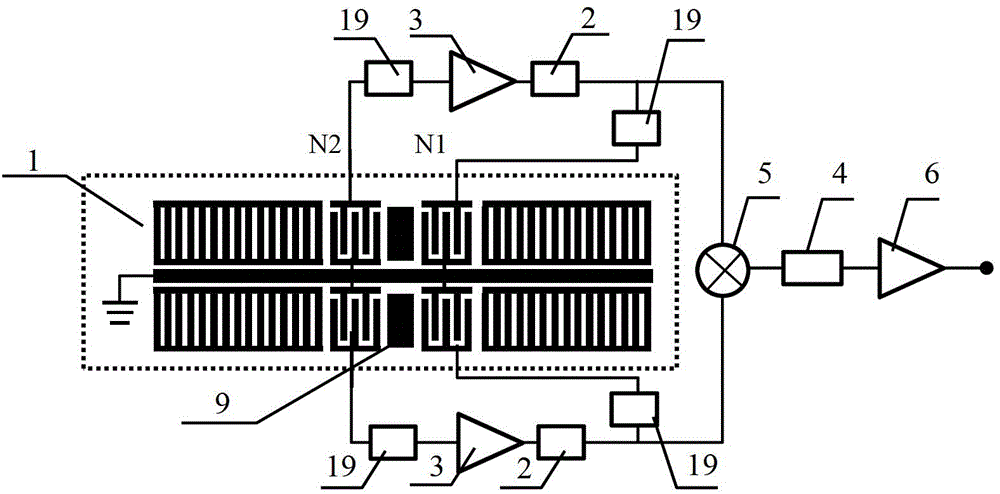

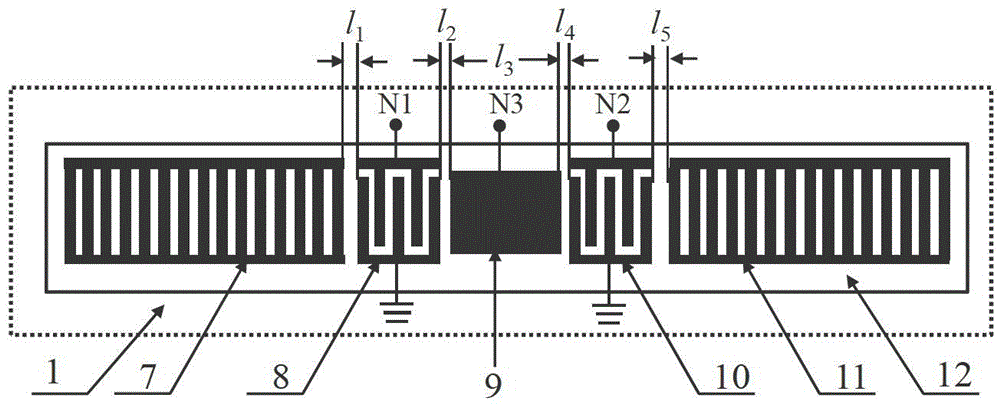

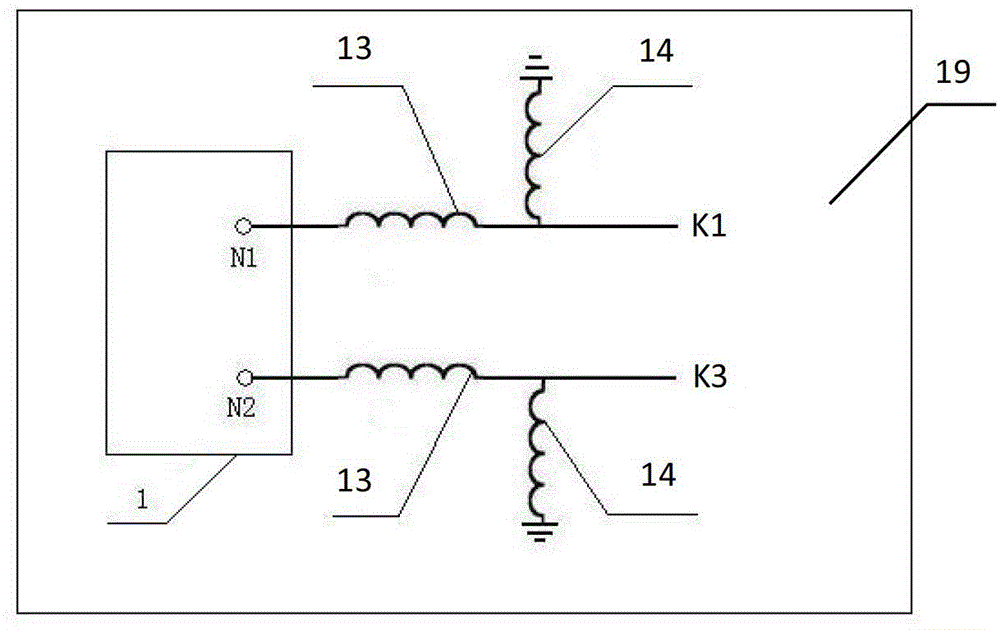

[0041] The resonant SAW oscillator system for gas sensors provided by the present invention includes: two groups of SAW oscillators made up of SAW resonators 1, phase-shifting network 2 and operational amplifier 3, and a mixer 5, a low-pass A mixing circuit composed of filter 4 and low frequency amplifier 6, the specific structure is as figure 1 shown. For each group of SAW oscillators in this system, the SAW resonator acts as the feedback element of the oscillator.

[0042] The two groups of SAW resonators 1 are fabricated on the same piezoelectric substrate 12 to eliminate the influence of the external environment to the greatest extent.

[0043] refer to figure 1 , making a SAW resonant oscillator system for gas sensors, such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com