Pneumatic radial tire for automobiles

A radial tire, passenger car technology, applied in the reinforcement layer of pneumatic tires, special tires, tire parts, etc., can solve the problems of poor fuel consumption, sacrificing vehicle space, and deteriorating interior comfort, and achieve interior comfort. and the effect of excellent uneven wear resistance and low fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

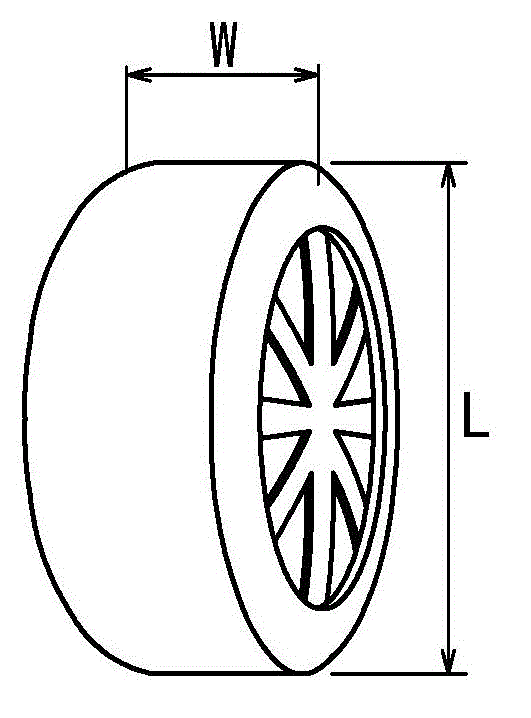

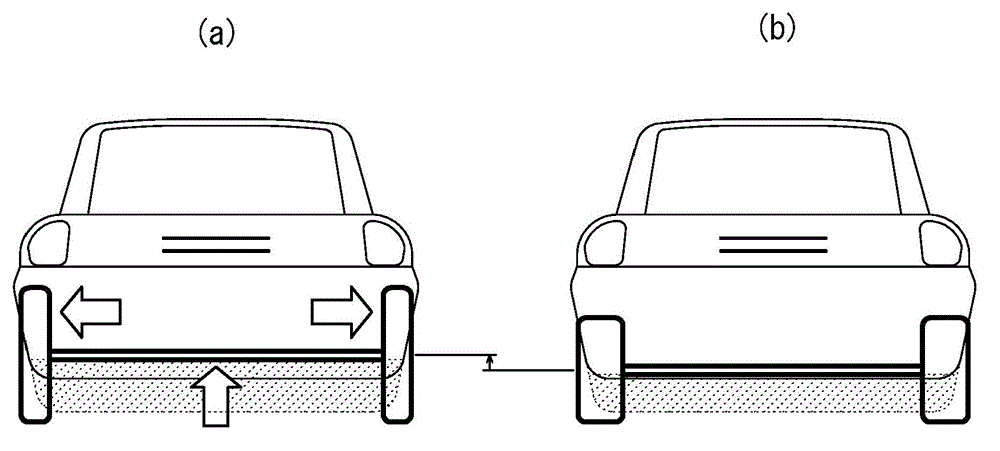

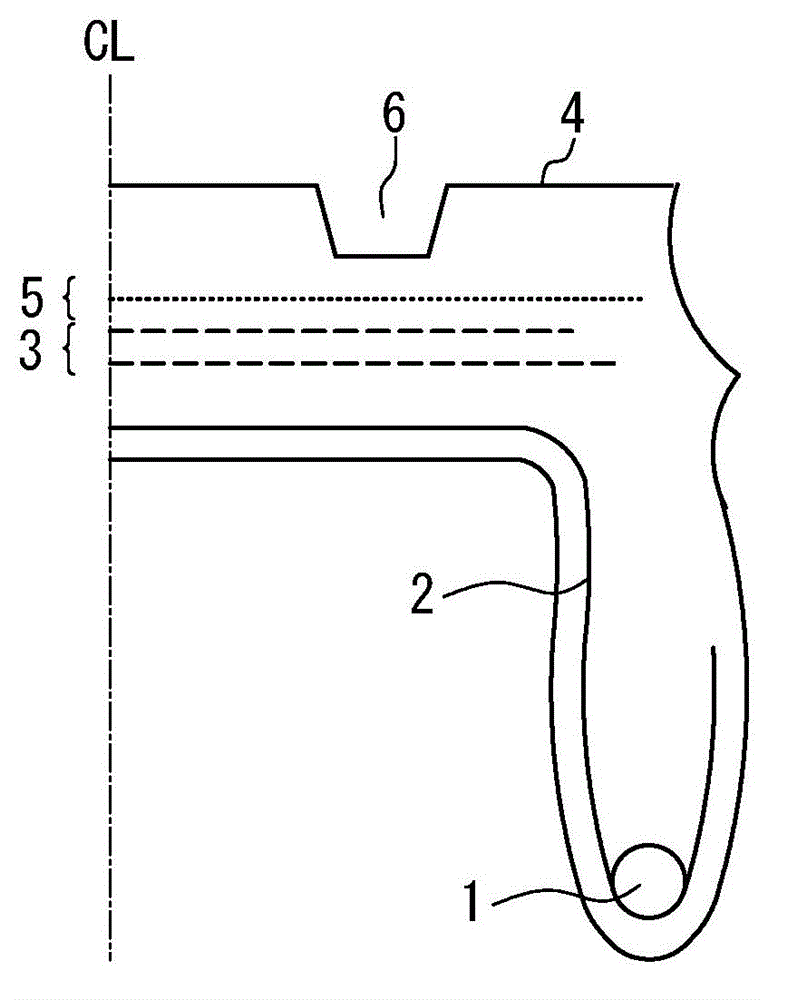

[0033] The process leading to the development of the pneumatic radial tire for passenger vehicles according to the present invention is described below. First, the inventors focused on how figure 1 The section width W of the radial tire is shown above, and it is found that by making the section width W as figure 2 As shown, the cross-sectional width of the tire is narrower than that of a conventional tire, and it is possible to ensure an internal space, especially a space for arranging drive components near the inner side of the tire mounted on a vehicle. In addition, a tire having a narrower section width W has a smaller area viewed from the front of the tire (hereinafter referred to as front projected area), which produces an effect of reducing air resistance of the vehicle. However, this involves a large deformation of the ground contact portion, causing the problem of a tire having a large rolling resistance at the same air pressure.

[0034] Furthermore, the inventors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com