Wire harness coiling and decoiling device of electrocardiograph

A technology of electrocardiogram machines and retractors, applied in sensors, medical science, diagnostic recording/measurement, etc., can solve problems such as delayed rescue time, tense relationship between doctors and patients, and signal lines affecting the rapid operation of medical staff, so as to prevent mutual entanglement , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

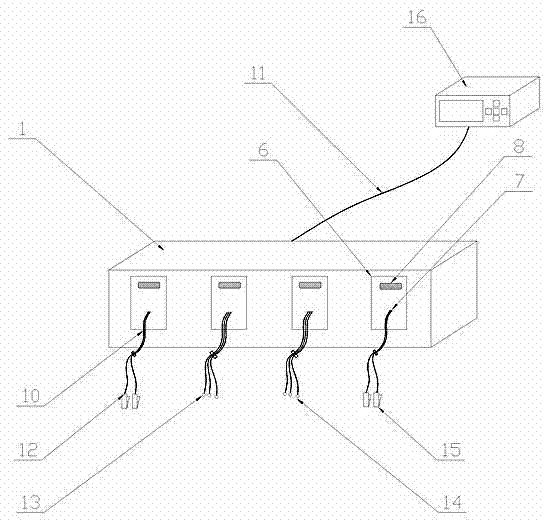

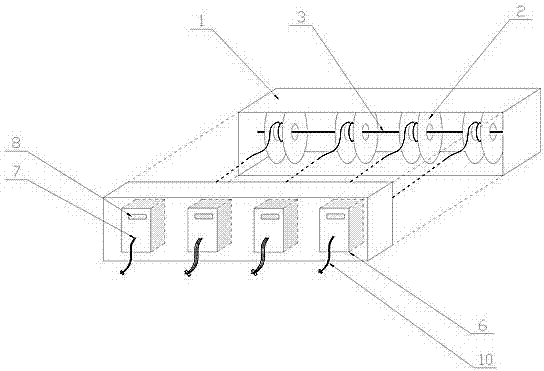

[0017] Such as figure 1 , 2 , shown in 3, same as prior art, there is the cable 11 that joins with electrocardiograph main frame 16, and cable 11 is respectively connected with two upper extremity clip-on probes 12, two lower extremity clip-on probes 15, the first group by signal line 10 The (three) chest suction cup probes 13 are connected to the second group (three) chest suction cup probes 14. The difference between embodiment 1 and the prior art is that a junction box body 1 is provided and fixed in the junction box 1. The four wire management ports 7 on the outer panel. The wire management ports 7 are through holes that are directly opened at the appropriate positions on the panel of the junction box body 1 and match the shape of the corresponding signal line 10. A shaft is fixed in the junction box body 1. 3. The reel 2 is slidingly connected with the shaft 3 through the shaft sleeve 21 integrated with it. The shaft 3 can be four shafts provided separately for each reel...

Embodiment 2

[0022] Such as Figure 4 , 5 , shown in 6, structure is basically the same as embodiment 1, difference is:

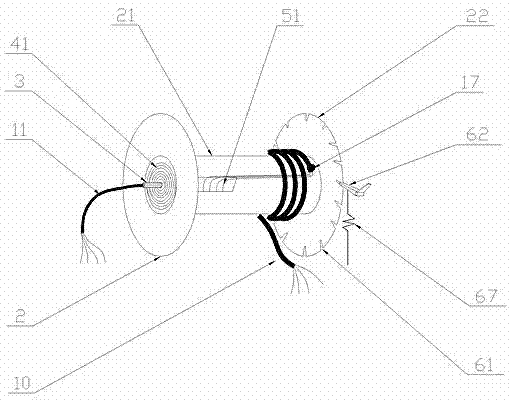

[0023] The driving device 4 of the reel 2 is a torsion spring 42 made of copper-plated or gold-plated steel wire, and the rotating jumper 5 is a copper-plated or gold-plated steel wire. The torsion springs 42 are fixed in the cavity formed between the shaft sleeve 21 of the reel 2 and the shaft 3, and the number is the same as the number of core wires of the corresponding signal lines 10. The torsion springs 42 are insulated from each other and arranged in a shielding arrangement. Copper or gold plating process Make sure it has high conductivity for signal transmission. The inner end of the torsion spring 42 is fixed to the shaft 3, the outer end of the torsion spring 42 is fixed to the axle sleeve 21 of the reel 2, and the two ends of the torsion spring 42 are respectively connected to the corresponding core wires of the signal line 10 and the cable 11.

[0024] The...

Embodiment 3

[0028] Such as Figure 7 Shown, structure is basically the same as embodiment 2, and difference is:

[0029] The rotating bridging device 5 is a transfer ring (or conductive bearing) 53 arranged in the cavity between the shaft sleeve 21 and the shaft 3 of the reel 2, the inner ring of the transfer ring 53 is fixed to the shaft 3, and the transfer ring 53 The outer ring of the wire reel 2 is fixed to the shaft sleeve 21 of the reel 2, and the inner ring and the outer ring of the power transfer ring 53 are slidably connected. And shielding arrangement and installation, the inner ring and the outer ring of the transfer ring 53 are respectively connected with the corresponding core wires of the cable 11 and the signal line 10 .

[0030] The reel driving device 4 of the reel 2 adopts a motor 43, and the motor 43 is connected with the reel 2 through gears. The wire harness locking control device 6 is composed of a wire take-up control button 8 and a control circuit.

[0031] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com