Dedusting and desulfuration integrated device for smoke and application of integrated device

A flue gas and desulfurization tower technology, applied in the field of integrated devices, can solve the problems of unsatisfactory dust removal requirements, unstable working conditions, and high cost of desulfurization agents, so as to reduce regeneration time, energy consumption, primary input cost, and reduce washing The number of series, the effect of reducing the number of acid pools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

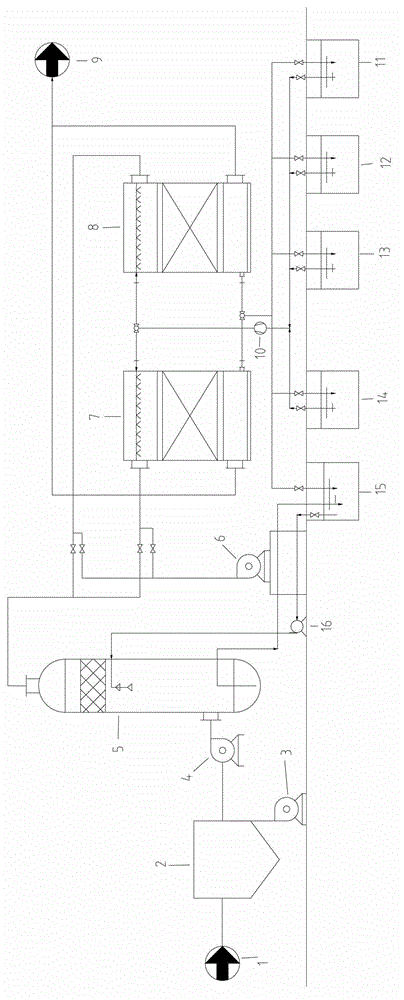

[0025] An integrated device for dust removal and desulfurization of flue gas, its structure is as follows figure 1 As shown, it includes bag filter 2, cooling and humidifying tower 5, desulfurization tower 7, 8 and washing liquid storage components, and the desulfurization tower adopts the method of two towers connected in series.

[0026] When the dust removal and desulfurization operation starts, the flue gas first removes most of the dust in the bag filter 2. In order to prevent fouling of activated carbon, the dust content of flue gas after dedusting should be less than 200mg / m 3 , and the dust concentration can be kept at 50mg / m through the bag filter 3 Within the limit, it can slow down the occurrence of activated carbon scaling and compaction, and prolong the service life of activated carbon.

[0027] The flue gas after dust removal enters the cooling and humidifying tower 5 from the middle and lower part of the cooling and humidifying tower 5 under the traction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com