Internal peeling core head for hollow tube and drawing device thereof

A technology of stretching device and hollow tube, which is applied in the field of inner peeling core head and its stretching device, can solve the problems that the inner surface defects of the tube blank cannot be eliminated, and achieve the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

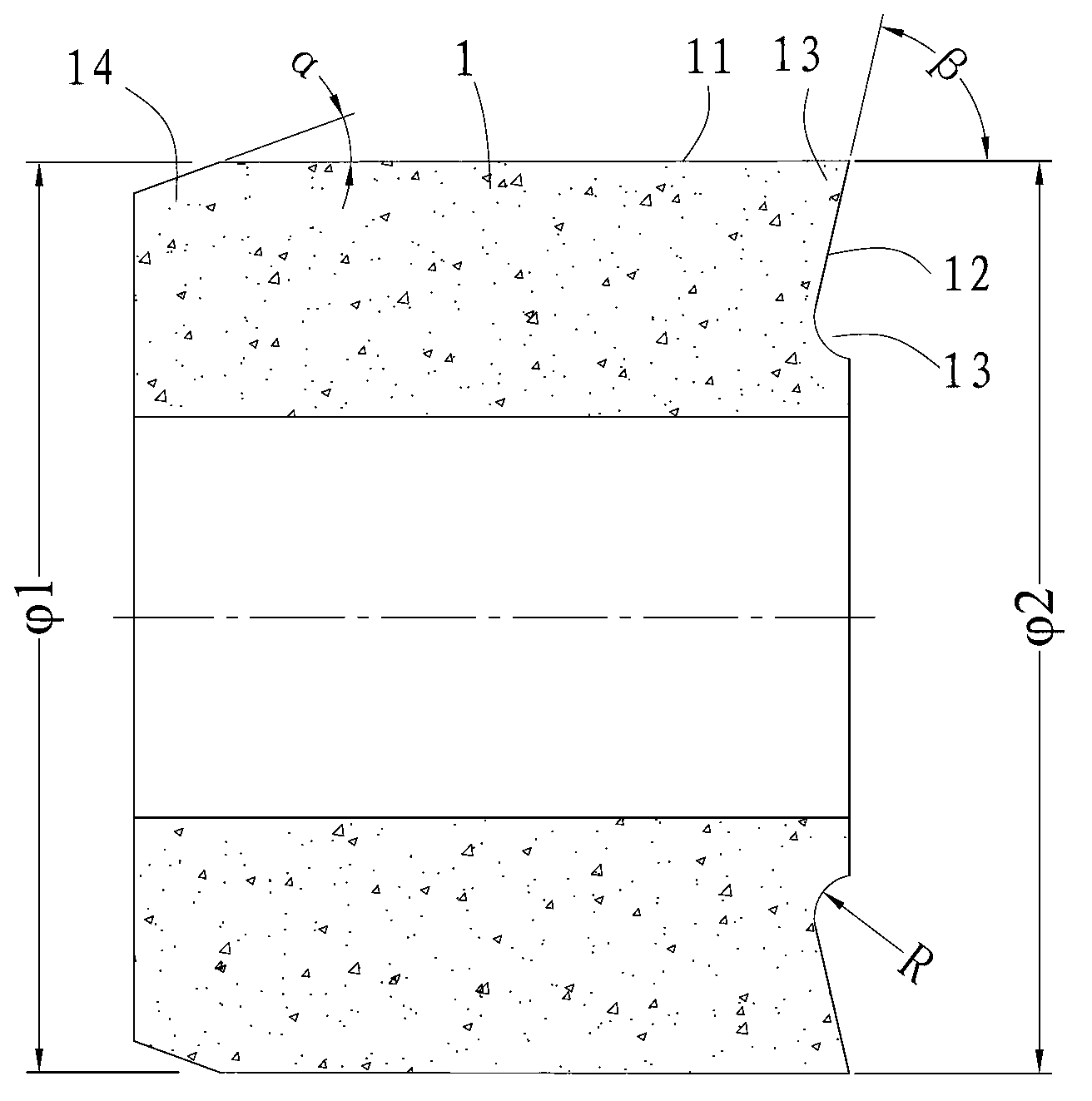

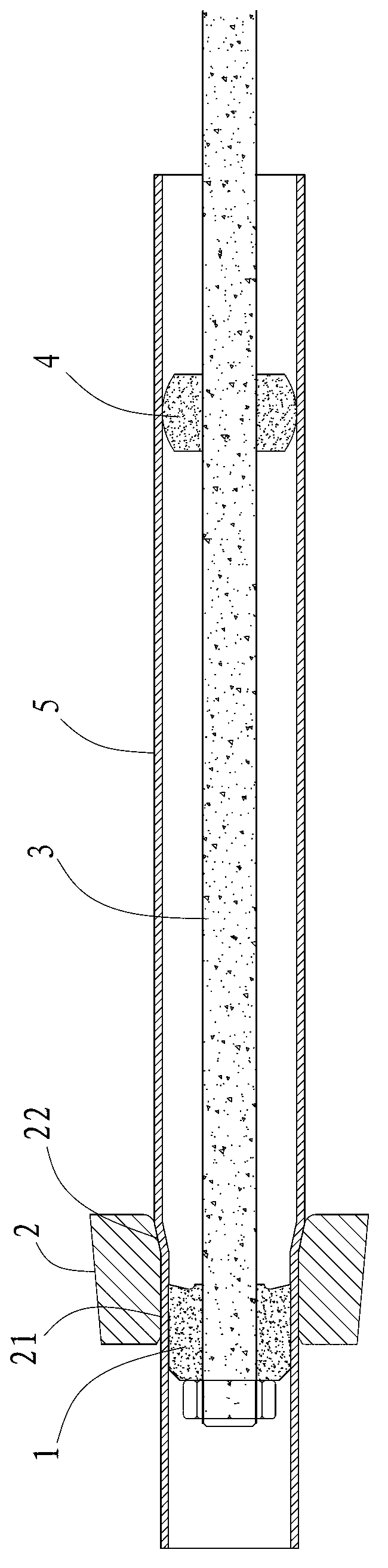

[0020] The invention proposes an inner peeling core head of a hollow pipe and a stretching device thereof, in which a tapered peeling edge is formed at the intersection of the outer surface of the core body and the rear end surface, the strength of the peeling edge is greatly improved, and the core body It can cooperate with the drawing die to ensure the diameter accuracy of the stretched pipe while completing the inner peeling. Finally, the stable internal peeling and stretching of the hollow pipe can be realized, and the residual defects on the inner surface of the pipe can be evenly eliminated, and the quality of the inner surface can be improved.

[0021] The technical solutions of the embodiments of the present invention will be explained and described below in conjunction with the drawings of the embodiments of the present invention, but the following embodiments are only preferred embodiments of the present invention, not all of them. Based on the examples in the implem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap