Combined type telescopic gangway system of deep sea drilling ship

A deep-sea drilling and combined technology, which is applied in the direction of ship accessories, ships, cargo handling equipment, etc., can solve the problems of light load draft and small molded depth, occupy a large deck space, and have a high utilization rate of deck space, so as to save the use of space , Shorten the construction period and shorten the installation length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

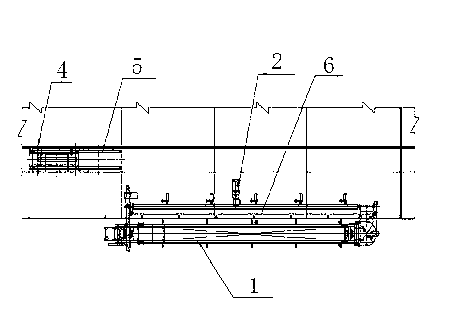

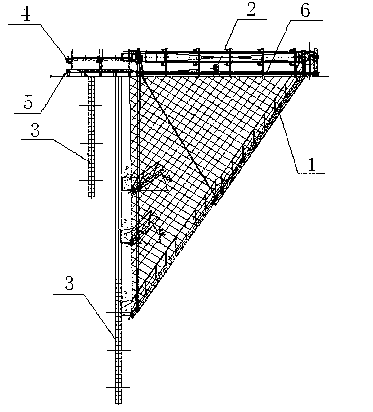

[0011] Such as figure 1 and figure 2 As shown, the combined telescopic gangway system of a deep-sea drilling ship includes a telescopic gangway 1, a power motor 2, a pilot ladder 3, a sliding winch 4 and a guide rail 5, and the telescopic gangway 1, the power motor 2 and the guide rail 5 are respectively installed on the deck 6, The pilot ladder 3 is installed on the sliding winch 4, and the sliding winch 4 is slidably installed on the guide rail 5. The combined telescopic gangway system of the present invention is suitable for shallow draft or large storage height and the installation length of the aluminum telescopic gangway 1 is limited. Under normal circumstances, the pilot ladder 4 slides on the guide rail 5, and after finding an appropriate position, lower the pilot ladder 3, so that the pilot can get off the platform from the gangway to the wharf or other ships through the ladder; in the case of deep draft and not exceeding 8m Under the situation, can directly promote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com