Spring steel sheet mark-free electrophoresis apparatus

A technology of spring steel sheet and electrophoresis device, which is applied in the direction of electrophoresis plating, electrolytic coating, coating, etc., can solve the problems of eccentric masking stickers and difficult removal of glue, and achieve the effects of low cost, good processing quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

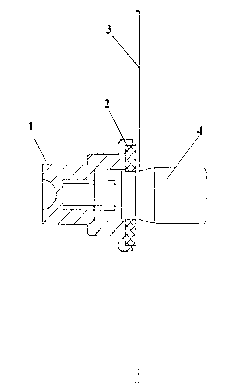

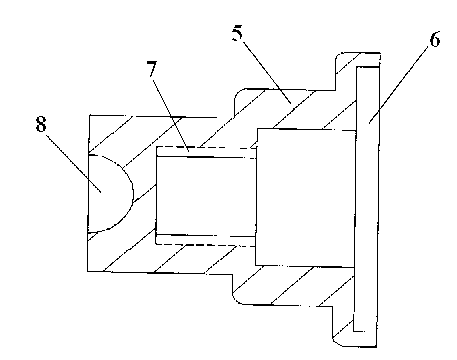

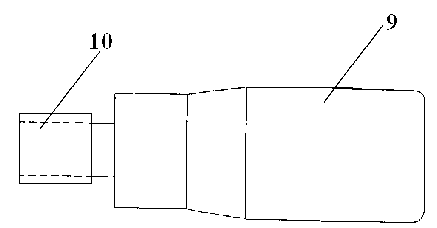

[0017] Below, the spring steel sheet traceless electrophoresis device of the present invention will be described in detail in conjunction with the accompanying drawings and embodiments:

[0018] Such as Figure 1~3 As shown, a spring steel sheet traceless electrophoresis device includes a positioning sleeve 1, a shielding sleeve 2 and a positioning mandrel 4. The positioning mandrel 4 passes through the center hole of the workpiece 3 to fix the workpiece 3 on the positioning sleeve 1. The positioning sleeve 1 includes a positioning sleeve body 5 with a stepped shape, and a stepped blind hole is formed inside the right end of the positioning sleeve body 5. The inner diameter of the stepped blind hole decreases from left to right, and the right end of the stepped blind hole is A circular groove 6 is provided with a shielding sleeve 2 in the circular groove 6. The left end of the stepped blind hole is an internal thread 7, and a semicircular groove 8 is formed on the left end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com