Wholly lifting construction method for asymmetric structure of huge overhang steel of high-rise building

An asymmetric structure, high-rise building technology, applied in building construction, construction, building maintenance and other directions, can solve the problems of high requirements for lifting and installation, high requirements for lifting and installation, and difficult to guarantee construction quality, and achieves low weight, The construction quality is easy to guarantee, and the effect of small amount of temporary facilities is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described below in conjunction with accompanying drawing and embodiment:

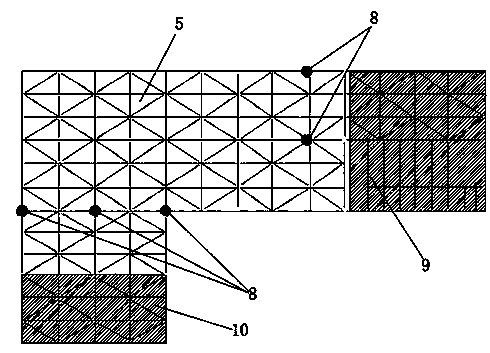

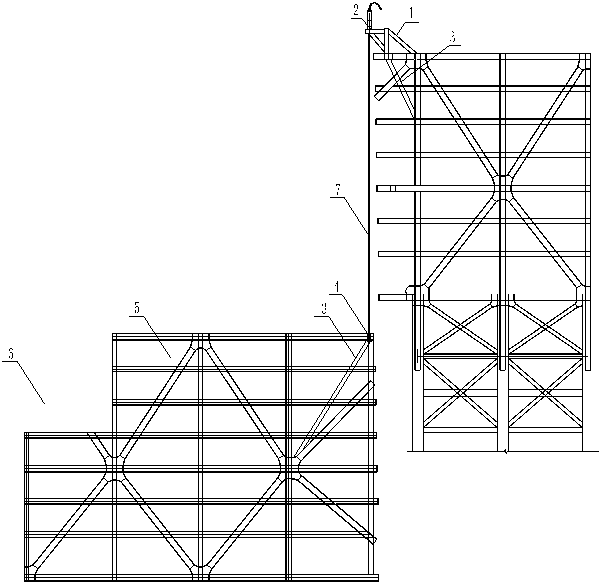

[0034] as attached figure 1 As shown, the hoisting part 5 of the giant steel structure truss of the present invention generally has a self-weight of more than 1000 tons. It is desired to lift such a heavy steel structure by a certain distance, and then to carry out merging with the existing building main body 9, 10 and then perform certain requirements. The connection construction is very difficult, and the lifting and installation requirements are high, especially the overall lifting of the roof or the giant cantilevered rigid asymmetric structure of the middle layer between the two adjacent building bodies 9 and 10. This lifting process is a The cubic steel corridor structure has force lifting lifting points 8 on the adjacent two sides of the horizontal plane, while the other adjacent two sides are completely suspended without force lifting lifting points. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com