Cyclone type jetting drill bit

A cyclone, drill bit technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of hindering the production efficiency of coal seam mining, restricting the development of productivity, and unable to sample at a fixed point, so as to improve the efficiency and safety of sampling, reduce Gas disaster accident, effect of saving sampling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

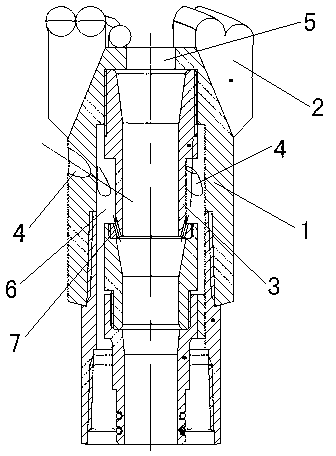

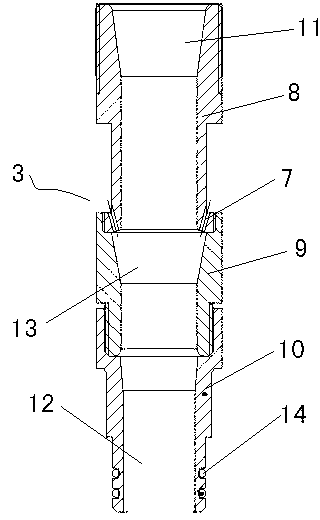

[0020] Such as figure 1 Shown is the cross-sectional view of the cyclone jet drill bit of the present invention, the cyclone jet drill bit of the present invention comprises a drill bit body 1 provided with a cavity, and a sampling port 5 communicating with the cavity is arranged in the middle of the end of the drill bit body 1, so The end of the drill bit body 1 is provided with a cutting bit 2 for drilling and sampling, and the wall of the drill bit body 1 near the cutting bit 2 is provided with a swirl jet hole 4 communicating with the cavity, and the swirl jet The centerline of the hole 4 and the axis of the drill body 1 intersect each other in space. The cyclone jet drill bit in this embodiment is used by cooperating with equipment such as double-wall drill pipes and drilling rigs.

[0021] During normal drilling, the drilling rig dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com