Continuous fiber reinforced thermoplastic composite high-pressure pipeline

A technology of reinforced thermoplastic and continuous fiber, which is applied in the direction of rigid pipes, pipe connection arrangements, pipes, etc., and can solve the problems of inability to meet high-pressure use requirements, inability to guarantee pipe strength, and weak impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

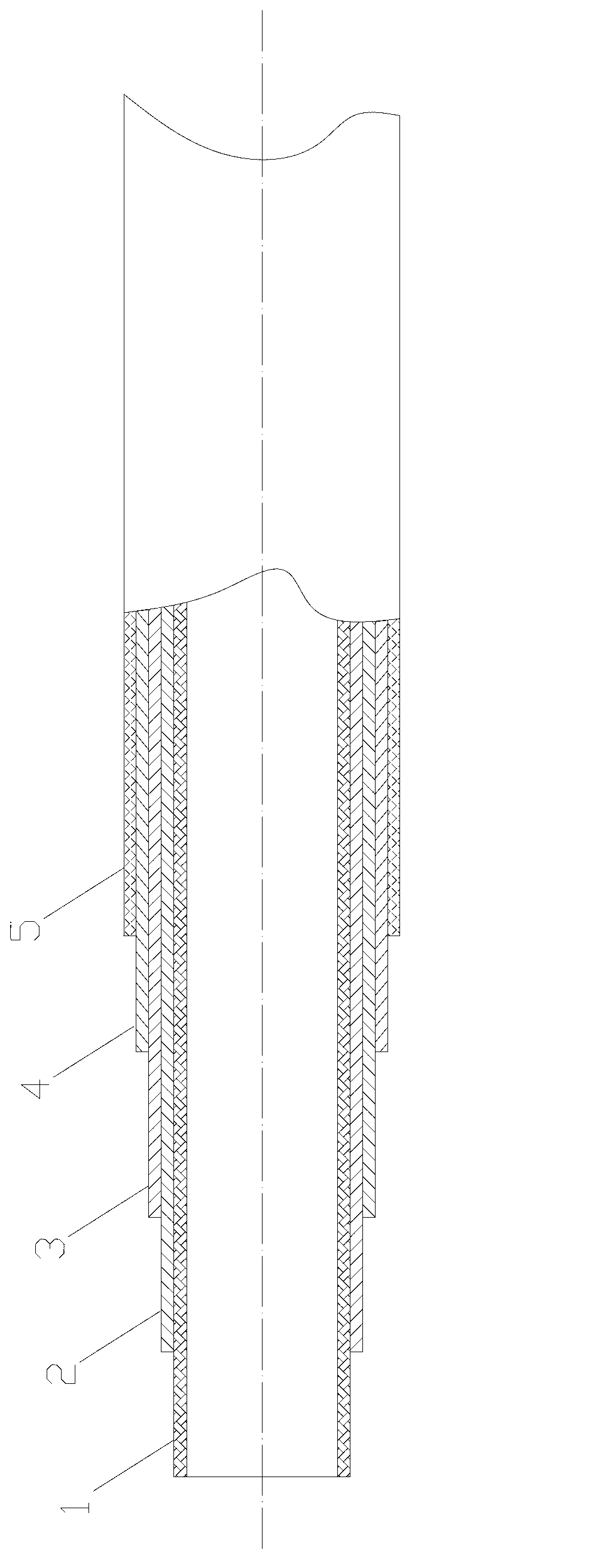

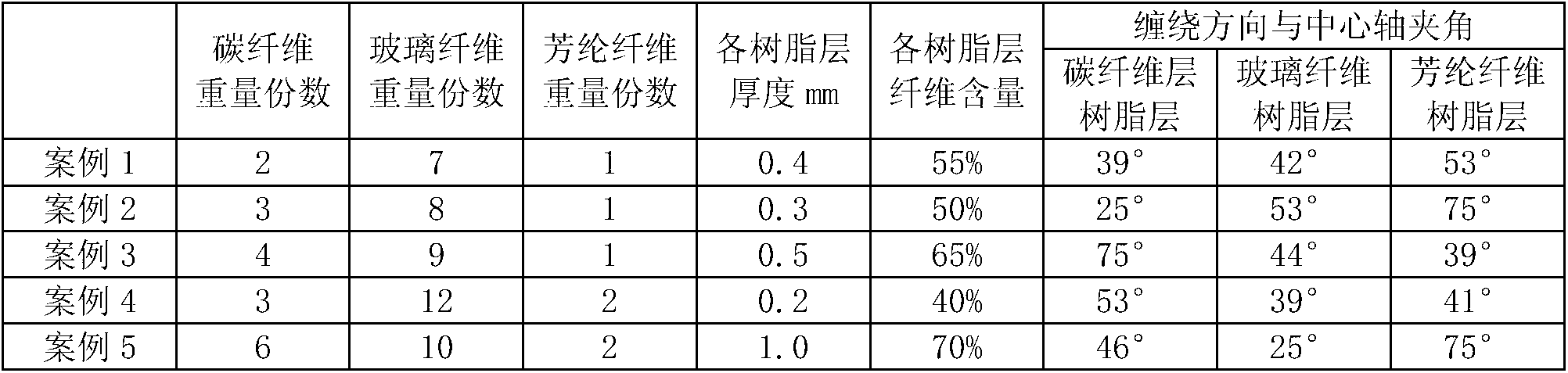

[0032] The continuous fiber reinforced thermoplastic composite high-pressure pipe of this embodiment, such as figure 1 As shown, there is an inner wall 1 and an outer wall 5, and an intermediate layer is arranged between the inner wall 1 and the outer wall 5; the inner wall 1 and the outer wall 5 are respectively made of thermoplastic resin materials; the intermediate layer is formed by thermoplastic compounding of multiple fiber resin layers Continuous fiber resin reinforcement layer, each fiber resin layer includes at least one layer (one layer in this embodiment) of carbon fiber resin layer 2 near the inner wall 1, at least one layer (one layer in this embodiment) of aramid fiber resin near the outer wall 5 Layer 4, and at least one layer (one layer in this embodiment) glass fiber resin layer 3 between the carbon fiber resin layer 2 and the aramid fiber resin layer 4; the carbon fiber resin layer 2 is preformed by continuous carbon fiber bundles and thermoplastic resin mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com