Novel mobile heat accumulation and release method and mobile heat supply device

A heat supply device, heat storage and release technology, applied to heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of long heat storage and release time, large equipment investment, poor economic benefits, etc. Fast heat release, low equipment investment, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

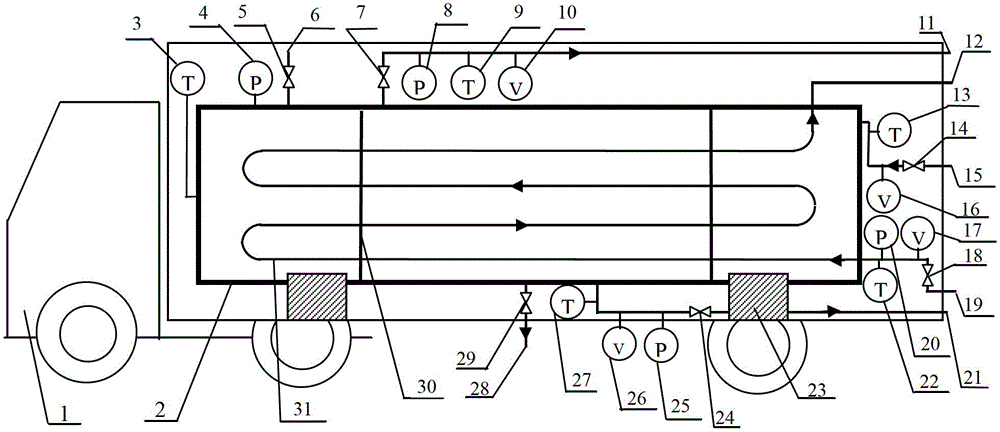

[0030] Combine figure 1 , A mobile heating device comprising a water storage tank 2 and a truck 1. The water storage tank 2 is fixed on the truck 1 through a base 23, and the water storage tank 2 is connected with a first pressure gauge 4 and a first The thermometer 3 is also connected with a pressure relief pipe 6, and a pressure relief valve 5 is provided on the pressure relief pipe 6. The water storage tank 2 is provided with a heat exchange tube 31 inside, and the inlet and the outlet 12 of the heat exchange tube 31 are located outside the water storage tank 2. The heat exchange tube 31 is of a vertical tube type, a horizontal tube type, or a coil type, and the inner and outer surfaces of the heat exchange tube 31 are smooth or finned surfaces.

[0031] The water storage tank 2 is connected with a cold water injection pipe 15, and the cold water injection pipe 15 is connected with a second valve 14, a second flow meter 16, and a second temperature meter 13. A third pressure...

Embodiment 2

[0034] Embodiment 1 The heat storage and release method of a mobile heating device includes the following steps:

[0035] (1) Heat storage process: inject cold water into the water storage tank 2, the liquid level of the cold water is higher than the heat exchange tube 31 inside the water storage tank 2, and the high temperature fluid is passed into the heat exchange tube 31 and the water storage tank 2 The cold water exchanges heat, the pressure and temperature in the water storage tank 2 reach a predetermined value, the high-temperature fluid is stopped passing through the heat exchange tube 31, and the heat storage of the water storage tank 2 ends.

[0036] (2) Heat release process: The steam outlet pipe 11 at the top of the storage tank 2 releases steam of different temperatures and pressures through valve adjustment, and the hot water outlet pipe 21 at the bottom of the heat storage tank 2 produces different temperatures and pressures by mixing with cold water Hot water.

[003...

example 1

[0044] Example 1: An industrial boiler produces about 3 tons of high-temperature and high-pressure saturated water per hour. The saturated water temperature is 240℃~260℃, pressure: 3.35Mpa~4.68Mpa, and a mobile heating device with a load of 15 tons of hot water is used for waste heat recovery , High-temperature and high-pressure saturated water is passed into the heat exchange tube of the mobile heating device to heat the low-temperature water in the storage tank to prepare high-temperature and high-pressure saturated water. The temperature of the saturated water is between 100°C and 240°C, and the saturation pressure is 0.101Mpa ~3.35Mpa, the higher the temperature and pressure of saturated water, the longer the charging time. Multiple mobile heating devices can also be connected in series for heating, which can achieve continuous heating and improve heating efficiency. The mobile heating device arrives at the factory that requires hot water and steam. The factory needs about 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com