Water tapped clay with foaming agent

A foaming agent and water cannon mud technology, applied in blasting, explosives and other directions, can solve the problems of inability to extinguish flame, easy deformation and water seepage, and can not achieve blocking effect, so as to reduce the incidence of accidents, cannon cannons, etc. Excellent hole plugging and easy filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

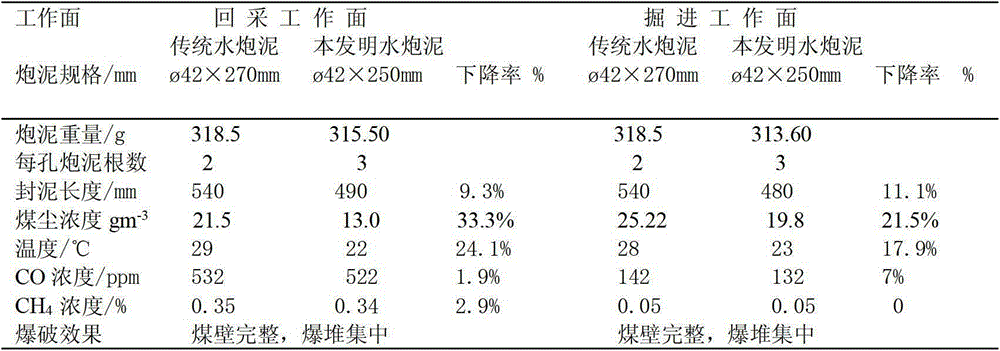

[0025] Example 1 Water blasting mud containing only foaming agent of the present invention

[0026] Dissolve a certain amount of sodium nitrite in water and mix it evenly, and then send it to the RCEG-12Rotaclip packaging machine produced by Dibot Corporation for canning. The outer packaging film 1 uses a commercially available PE dry composite film to produce water gun mud , The aqueous solution of water gun mud contains 0.37% sodium nitrite.

[0027] When the water cannon mud obtained in this example is used in coal mining, after the explosives and detonators are filled according to the blasting design specification, 3 water cannon mud are installed in each blast hole, and the holes are blocked after the water cannon mud, mainly with three-layer soil Or clay, according to the length and length of the blast hole, until it is fully blocked.

[0028] Table 1 shows the results of the field comparative test of the water cannon mud of this embodiment and the traditional water cannon mud...

Embodiment 2

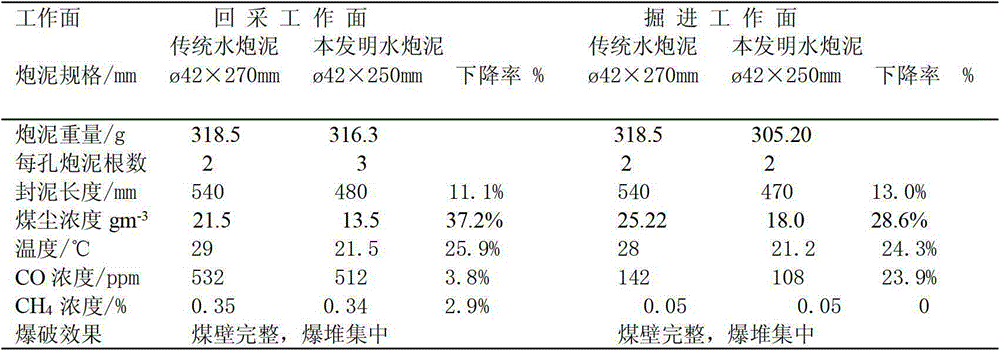

[0031] Example 2 The water cannon mud containing foaming agent and sodium bicarbonate of the present invention

[0032] Dissolve a certain amount of sodium nitrite and sodium bicarbonate in water and mix them evenly, and then send them to the RCEG-12Rotaclip packaging machine produced by American Dibote Company for canning. The outer packaging film 1 uses a commercially available PE dry composite film to produce The water cannon mud is obtained, and the aqueous solution of the water cannon mud contains 0.4% sodium nitrite and 2% sodium bicarbonate.

[0033] When the water cannon mud obtained in this embodiment is used in coal mining, after the explosives and detonators are filled according to the blasting design specification, two water cannon muds are installed in each blast hole, and the holes are blocked after the water cannon mud. Or clay, according to the length and length of the blast hole, until it is fully blocked.

[0034] Table 2 shows the field comparative test results of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com