Launcher based on Hopkinson pull rod test equipment

A technology for testing equipment and launching devices, which is applied in the field of launching devices, can solve problems such as the impact of test loading consistency, poor test consistency, and small bullet loading force, and achieve the effects of good test consistency, low cost, and avoiding bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

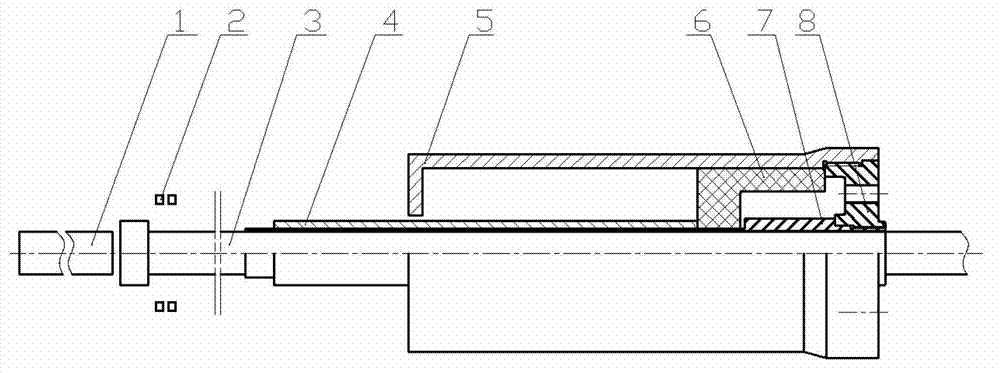

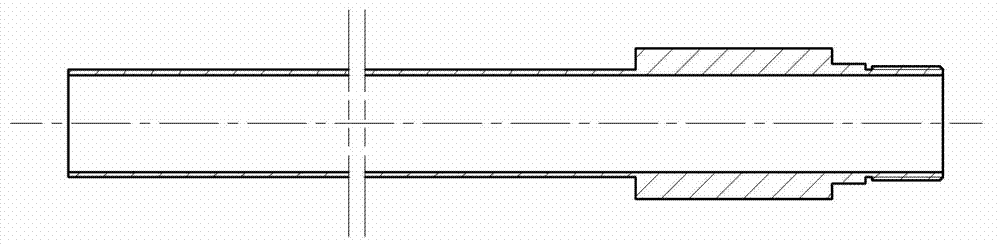

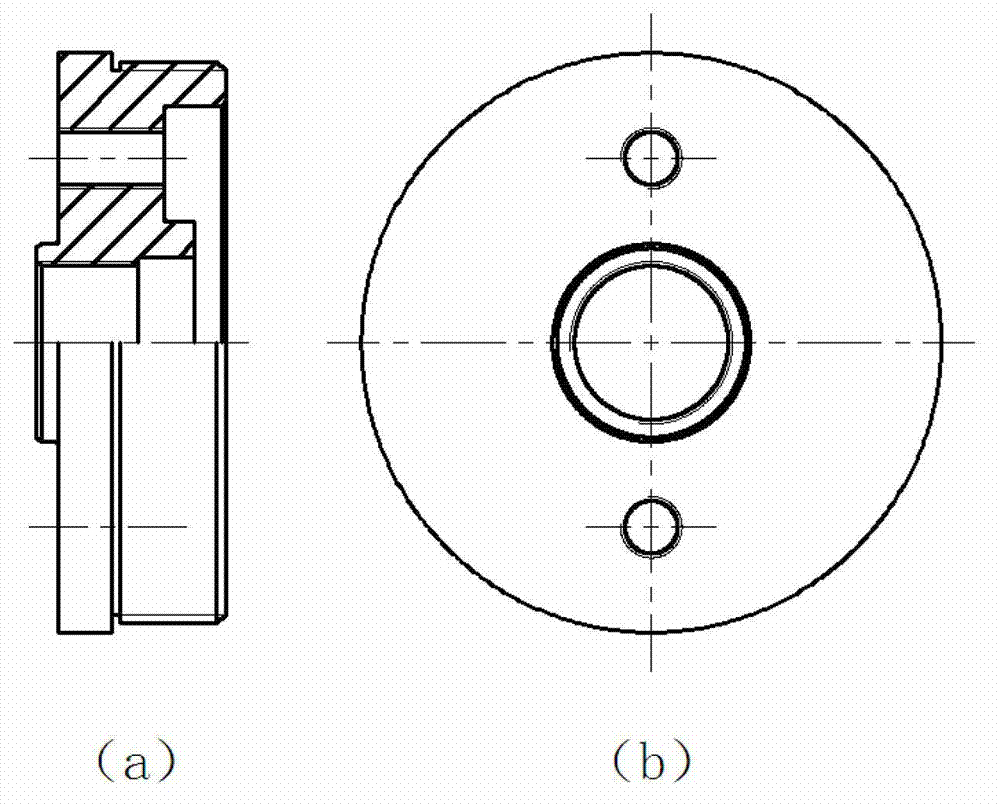

[0012] A firing device used on a Hopkinson pull rod of the present invention is used to provide a certain speed for bullets. The sleeve is used as the movement track of the piston, and is welded and fixed on the support seat; the base is fixed on the sleeve, and two ventilation holes are symmetrically distributed on its radius; a thin-walled circular tube with a diameter slightly larger than the rod is designed as the track of the tubular bullet. The high-pressure gas enters the sleeve through the vent hole of the base, and the piston accelerates along the inner wall of the sleeve under the action of the pressure difference between the two ends, and at the same time pushes the tubular bullet to move along the thin-walled track.

[0013] In conjunction with accompanying drawing, a kind of launching device based on Hopkinson pull rod test equipment of the present invention is characterized in that, comprises absorbing rod 1, laser velocimeter 2, incident rod 3, tubular bullet 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com