Comprehensive industrial real-time data monitoring system and method thereof

A real-time data monitoring and industrial technology, applied in the direction of comprehensive factory control, comprehensive factory control, energy industry, etc., can solve the problems of not being able to meet the dynamic changes and expansion of the system, inconvenient unified assessment and management of workshop teams, and low data consistency. Achieve the effect of saving network communication costs, improving automation management level, and strong compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

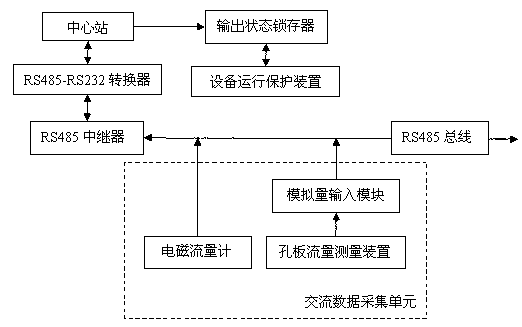

[0020] Such as figure 1 As shown, the comprehensive industrial real-time data monitoring system includes a central station, output status latch, RS485-RS232 converter, equipment operation protection device, RS485 repeater, RS485 bus, AC data acquisition unit, and the AC data acquisition unit includes analog Input module, electromagnetic flowmeter and orifice flow measuring device; equipment operation protection device, output status latch, central station, RS485-RS232 converter, RS485 repeater, RS485 bus connected in sequence, AC data acquisition unit, hole The board flow measuring device, the analog input module, and the RS485 bus are connected in sequence, and the electromagnetic flowmeter is connected to the RS485 bus.

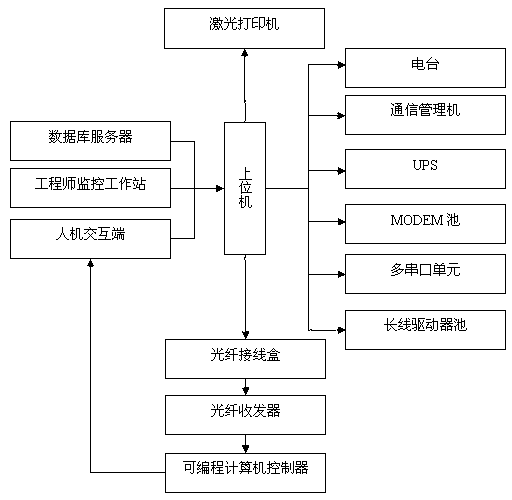

[0021] Such as figure 2 As shown, the central station includes a host computer, a laser printer, a database server, an engineer monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com