Light emitting diode with current barrier layer

A technology of light-emitting diodes and current blocking layers, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of inconsistent electrode colors, weak adhesion of light-emitting diodes, and low luminous intensity, so as to improve luminous intensity and improve luminous intensity. Extraction efficiency, effect of increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

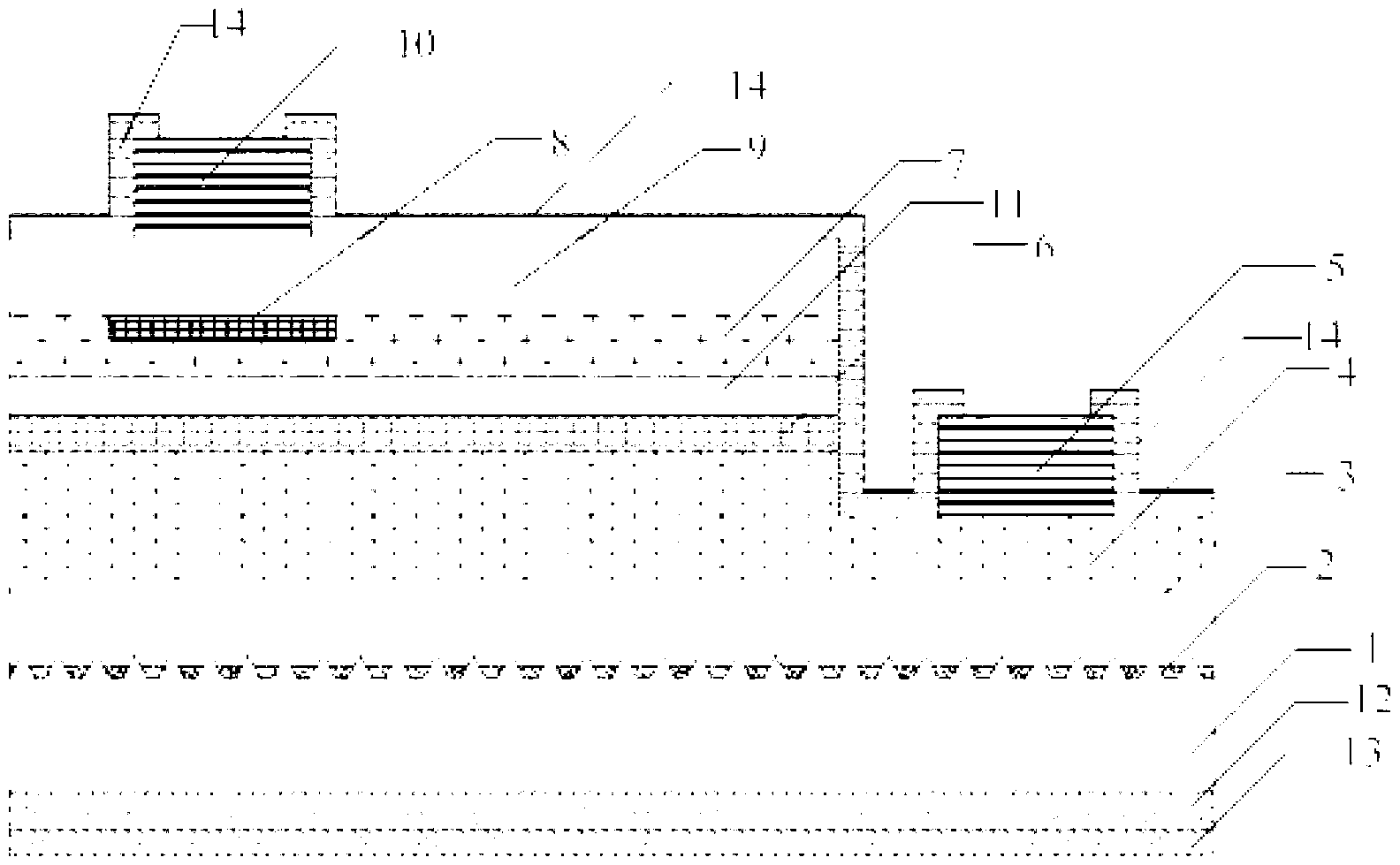

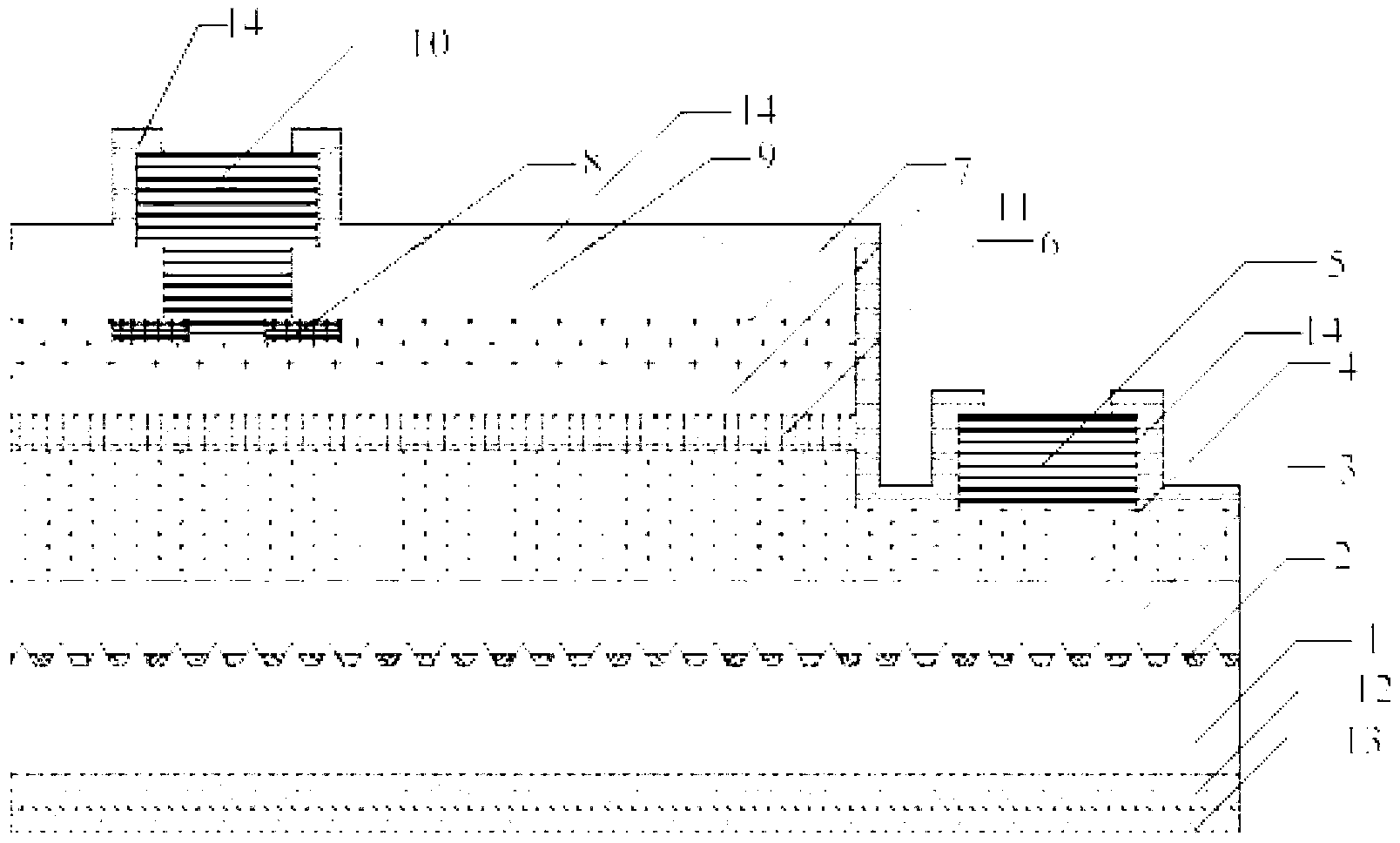

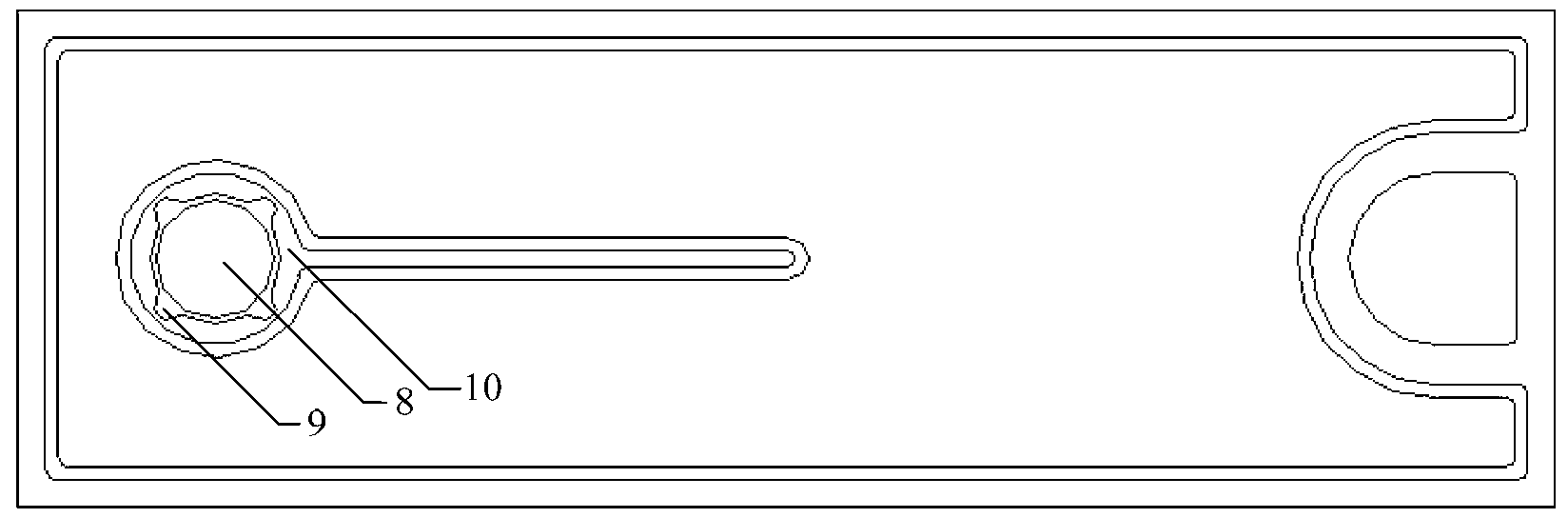

[0028] like figure 2 As shown, Embodiment 1 is a light-emitting diode with a current blocking layer. The common basic structure is: from bottom to top, it includes a substrate 1, a buffer layer 2, a non-doped GaN layer 3, an n-type GaN layer 4, and an n-type GaN layer. The n-electrode 5 formed on the GaN layer 4, the active layer 6, the p-type GaN layer 7, the current blocking layer 8, the transparent conductive layer 9 and the p-electrode 10 formed on the transparent conductive layer 9, in the transparent conductive layer 9 and The current blocking layer 8 is provided with an opening structure for enabling the p-electrode 10 to contact the p-type GaN layer 7 through the transparent conductive layer 9 and the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com