RC (Resistance-capacitance) type rotor crowbar

A resistance-capacitance and rotor technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, single-net parallel feeding arrangement, etc., can solve problems such as low-voltage ride-through that cannot be completely solved, and improve low-voltage ride-through capability , to achieve the effect of fast compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

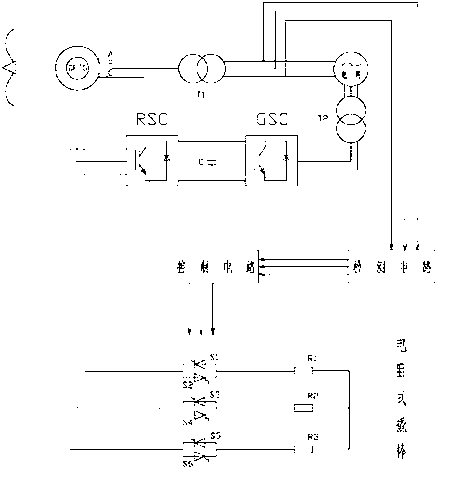

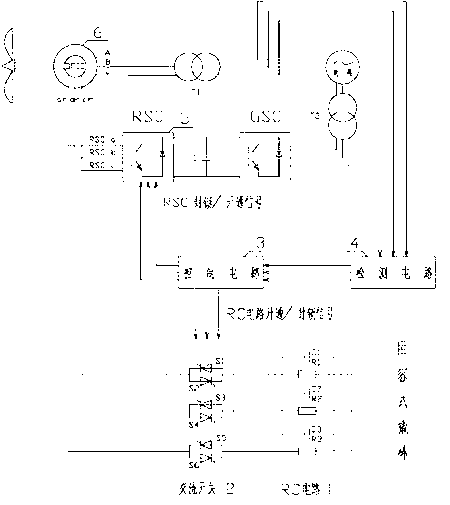

[0016] The structural diagram of the resistance-capacitance rotor crowbar applied to the DFIG system is as follows: figure 2 shown. The resistance-capacitance crowbar is composed of an RC circuit 1 , an AC switch 2 , a control circuit 3 and a detection circuit 4 . RC circuit 1 is a combined circuit of three sets of resistors and capacitors, each of which is a parallel connection of resistors and capacitors, respectively the first resistor R1 and the first capacitor C1, the second resistor R2 and the second capacitor C2, the third resistor R3 and Three groups of the third capacitor C3 form a three-phase combination form. One end of the resistance-capacitance rotor crowbar is connected to the rotor winding of DFIG 6 through the AC switch 2, and the other end is connected to each other to form a three-phase short circuit. The AC switch 2 is composed of three groups of anti-parallel thyristors, namely the first thyristor S1 and the second thyristor S2, the third thyristor S3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com