A target source preshaping enhanced EUV light generating device

A technology of extreme ultraviolet light generation device, which is applied in the direction of huge current X-ray tubes, discharge tubes, electrical components, etc., can solve the problems of low energy conversion efficiency of EUV light sources, and achieve improved energy conversion efficiency, increased output energy, Achieve the effect of optimal matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention solves the problem of low energy conversion efficiency of the EUV light source in the prior art by providing a target source pre-shaping enhancement device, improves the luminous efficiency of the EUV generating device, and increases the EUV light output energy of the device.

[0028] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

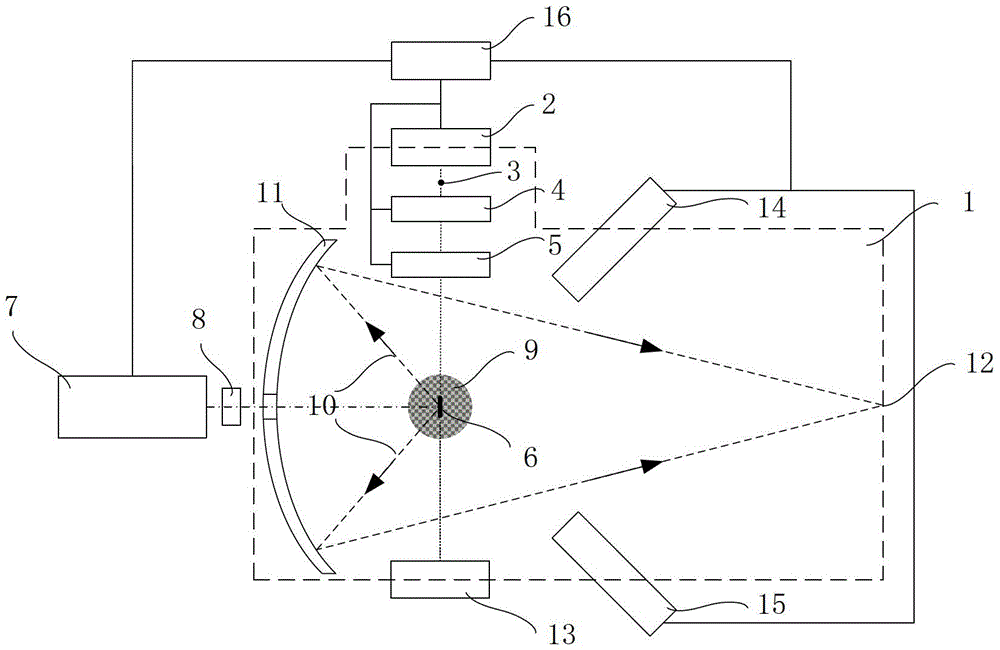

[0029] Such as figure 1 As shown, the embodiment of the present invention discloses a pre-shaping enhancement method and device, which is applied to an EUV light generating device. The EUV light generating device includes: a vacuum chamber 1, a target source generator 2, a target source 3, and a high-energy generator 7. Energy injector 8, EUV light collector 11, residual target collector 13, wherein,

[0030] The vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com