High-efficiency deodorization and low-nutritional content loss method of conducting wall breaking and deodorization to spirulina

A technology for spirulina and deodorization, which is applied in the fields of application, food preparation, food science, etc., can solve the problem of long time consumption, and achieve the effect of short time consumption, simple equipment and convenient subsequent processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

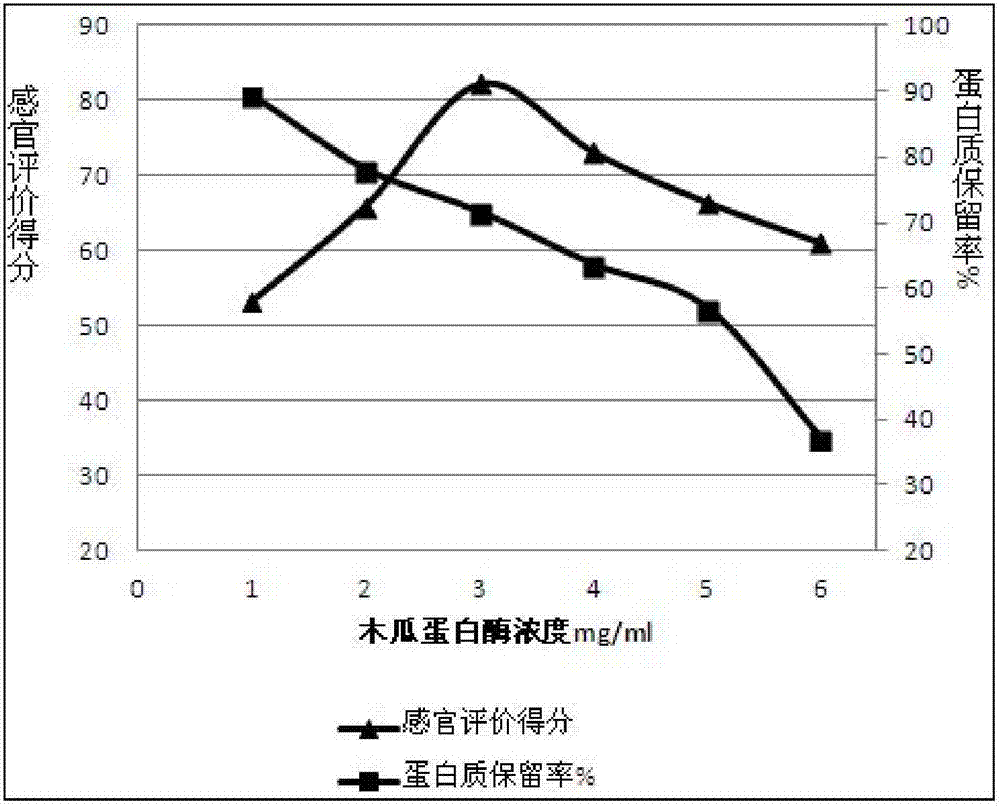

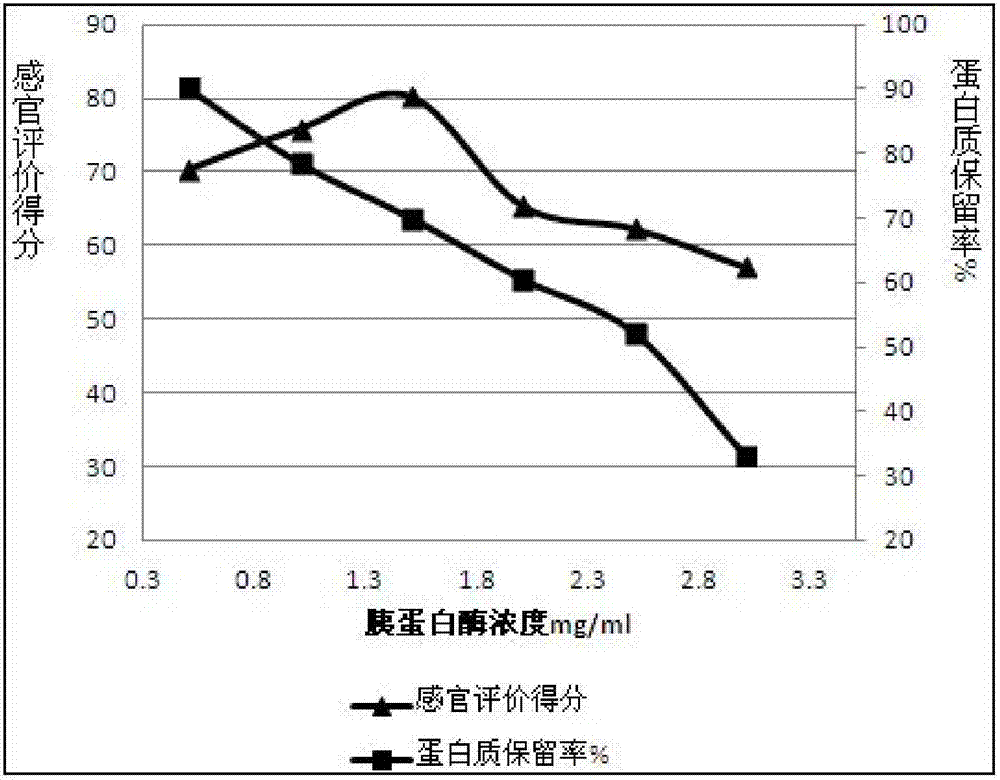

[0036] Embodiment 1 lysozyme-papain double enzyme method

[0037] 1. Weigh a certain amount of spirulina dry powder, add pure water and stir continuously to form a spirulina solution with a concentration of 12%, add lysozyme and papain to the spirulina solution, the dosage is 0.54mg / ml and 0.5mg / ml respectively ml, stirred evenly and then enzymatically hydrolyzed. During the enzymolysis process, ensure that the pH value of the solution is between 6.0 and 7.0, the temperature is 40°C, and the time is 1h. After the enzymatic hydrolysis, the wall breaking rate of Spirulina observed under a microscope was 97.3%, and the sensory evaluation was carried out at the same time, with a score of 80.9.

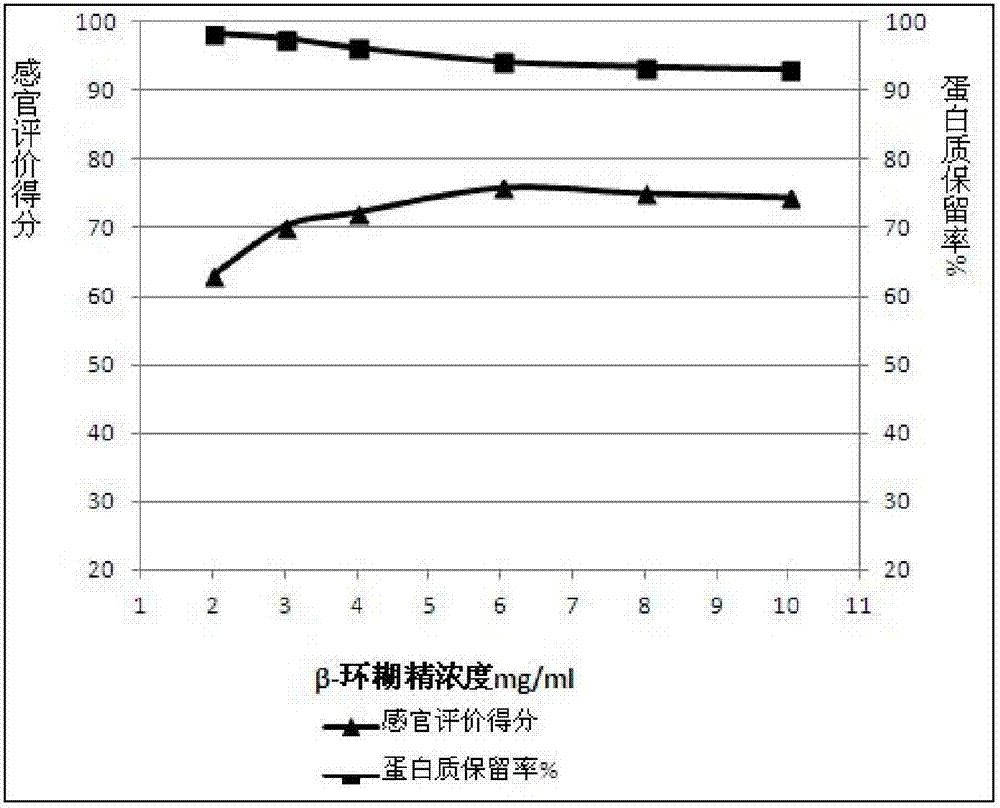

[0038] 2. After adding 4mg / ml of β-cyclodextrin to the hydrolyzed solution of Spirulina obtained in step 1, stir at 40°C for 40 minutes, filter and dry the deodorizing solution of Spirulina after masking treatment to obtain Spirulina Algae deodorization dry powder.

[0039] 3. Prepare 1...

Embodiment 2

[0042] Similar to Example 1, its difference is that during lysozyme-papain enzymolysis, the concentration of spirulina solution is 9%, the consumption of lysozyme is 0.135mg / ml, the consumption of papain is 1.125mg / ml, the enzymolysis temperature The temperature is 35°C, and the time is 3h. The amount of β-cyclodextrin used for β-cyclodextrin embedding was 5 mg / ml, the temperature was 35° C., and the stirring time was 45 minutes.

[0043] After the enzymatic hydrolysis, the wall breaking rate of Spirulina observed under a microscope was 97.4%, and the sensory evaluation score was 78.6 points. The solution prepared by β-cyclodextrin-embedded spirulina deodorization dry powder has basically no fishy smell, the color is light blue-green (close to light blue), and the solution has basically no precipitation. The sensory evaluation score is 91.3 points, and the protein retention The rate is 95.2%.

Embodiment 3

[0045] Similar to Example 1, its difference is that during lysozyme-papain enzymolysis, the concentration of spirulina solution is 15%, the consumption of lysozyme is 0.45mg / ml, the consumption of papain is 1.25mg / ml, the enzymolysis temperature The temperature is 30°C, the time is 2h, the dosage of β-cyclodextrin is 5mg / ml when β-cyclodextrin is embedded, the temperature is 30°C, and the stirring time is 50min.

[0046] After the enzymatic hydrolysis, the wall breaking rate of Spirulina observed under a microscope was 98.1%, and the sensory evaluation score was 76.9. The solution prepared by β-cyclodextrin-embedded spirulina deodorized dry powder has basically no fishy smell, the color is light blue-green (close to light green), the solution basically has no precipitation, the sensory evaluation score is 90.4 points, and the protein retention rate 95.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com