Polycrystalline silicon numerically controlled grinder

A technology for CNC grinding machines and polysilicon blocks, which is applied to grinding machines, machine tools suitable for grinding workpiece planes, and machine tools suitable for grinding workpiece edges, etc., which can solve difficult silicon square machining accuracy and accuracy stability and uncertainty Factors increase, increase the number of equipment requirements and other issues, to achieve the effect of reducing processing costs, good stability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

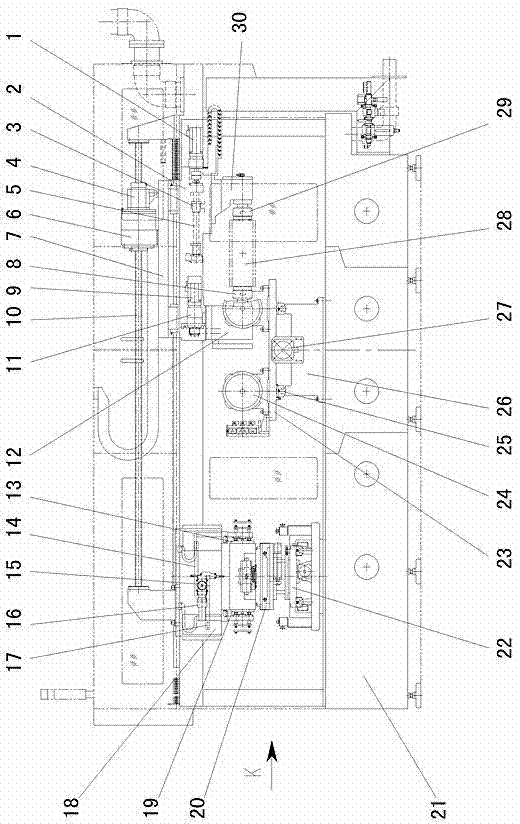

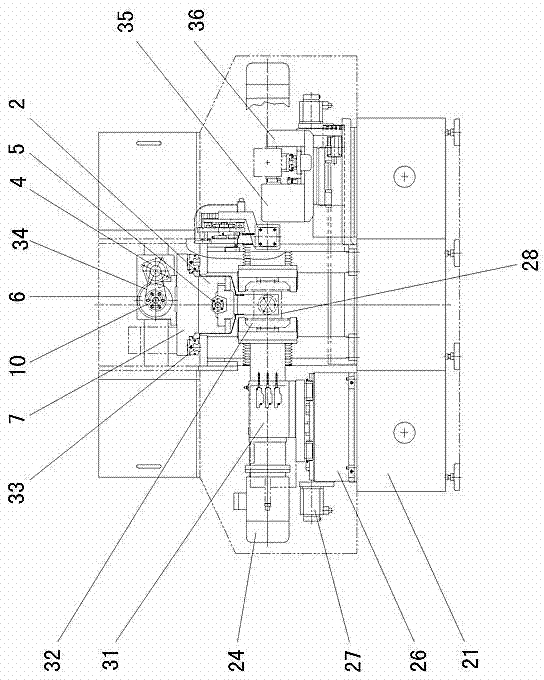

[0013] like figure 1 , 2 Shown: 21 is machine base, and the middle part of machine base 21 is positioned at the front side and rear side horizontally and is respectively provided with symmetrical two pairs of totally four groups of grinding mechanisms, and grinding mechanism is arranged on the grinding slide 23. The grinding mechanism includes a grinding spindle 31 fixed on the grinding slide 23. The input shaft of the grinding spindle 31 is connected to the grinding motor 24, and the output shaft end is equipped with a grinding disc 32, which is a disc-shaped grinding wheel. The end of the motor 24 is fixedly connected with the end of the grinding spindle 31 by bolts.

[0014] The grinding slide 23 is located on the grinding track 25 through the slider below it, the grinding track 25 is fixed on the grinding seat 26, the grinding seat 26 is fixedly connected with the machine base 21, and the grinding slide 23 is connected to the grinding track 25. A screw nut driving mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com