Multi-effect evaporative sea water desalinating device with hybrid process

A multi-effect evaporation and effect evaporation technology, which is applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc., can solve the problems of evaporation/condenser scaling, increase the workload of device maintenance, and bury hidden dangers in safe operation. , to achieve the effect of simplifying the extraction design, reducing the maintenance workload and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

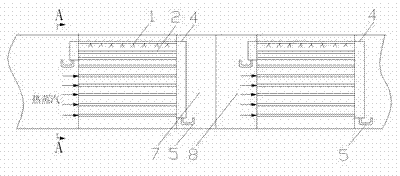

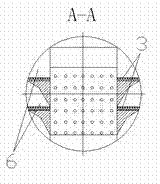

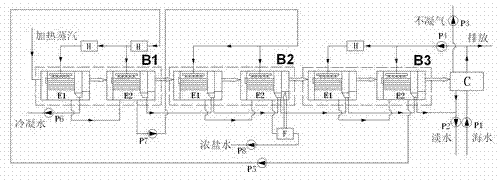

[0015] figure 1 , 2 A structural diagram of adjacent two-effect evaporators within the same group is shown. In the figure, the seawater inlet pipe on the upper part of the tube bundle and the seawater spraying device 1 spray the seawater evenly onto the tube bundle 2, the seawater flowing in the falling film between the tube bundles is partially evaporated by the steam inside the tubes, and the generated water vapor flows along the gap between the tube bundles To the demister 3, then through the steam channel 6, it flows into the tail head 7 of the effect evaporator / condenser, and the tail head 7 of the 1st effect evaporator / condenser is connected with the steam inlet pipe box 8 of the 2nd effect evaporator / condenser , the secondary steam generated by the 1-effect evaporator / condenser enters the steam inlet tube of the 2-effect evaporator / condenser. The steam in the pipe condenses and releases heat when spraying seawater outside the heating pipe, and becomes the product wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com