Low-temperature frost-free heat pump system and method for exhaust sensible heat regeneration

A heat pump system, low temperature technology, applied in the field of heat pump, can solve the problems of insufficient spray density, high irreversible loss of heat transfer, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

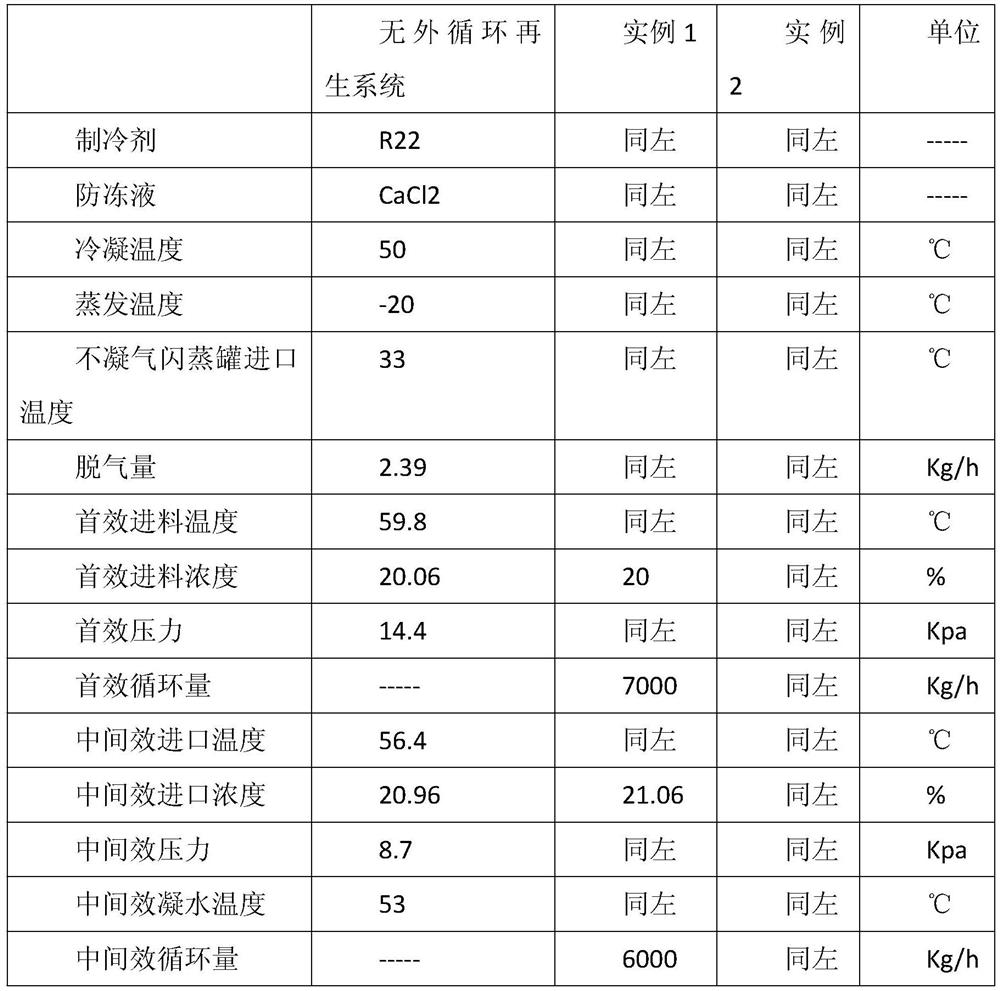

Embodiment 1

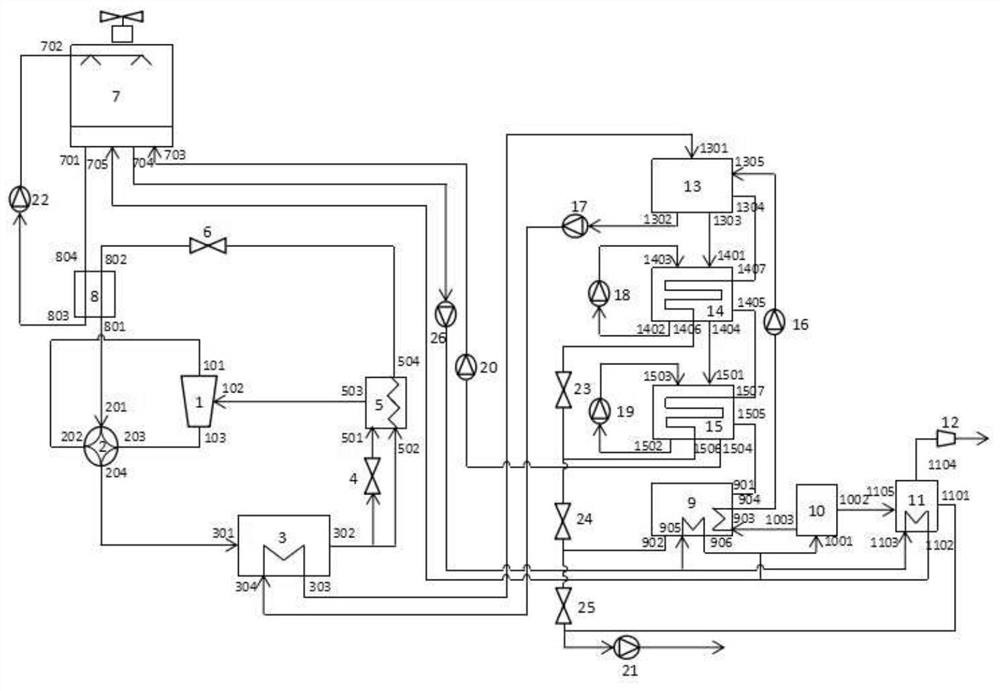

[0079] Embodiment 1, the low-temperature frost-free heat pump system form one of exhaust sensible heat regeneration, such as figure 1 Shown, including heat pump circulation system and solution regeneration system.

[0080] The heat pump cycle system includes a compressor 1, a four-way reversing valve 2, a coupled condensing heat exchanger 3, a first throttle valve 4, an economizer 5, a second throttle valve 6, a heat exchanger 8, a heat source tower 7, and a solution pump 22. Compressor 1 is an air injection enthalpy increasing compressor.

[0081] The solution regeneration system includes a exhaust steam recovery chamber 11, a degasser 10, a condenser 9, a dilute solution pump 16, a first effect flash chamber 13, an intermediate effect evaporation chamber 14, a final effect evaporation chamber 15, a first effect circulation pump 17, Intermediate effect circulation pump 18, final effect circulation pump 19, concentrated solution pump 20, condensate water pump 21, vacuum pump...

Embodiment 2

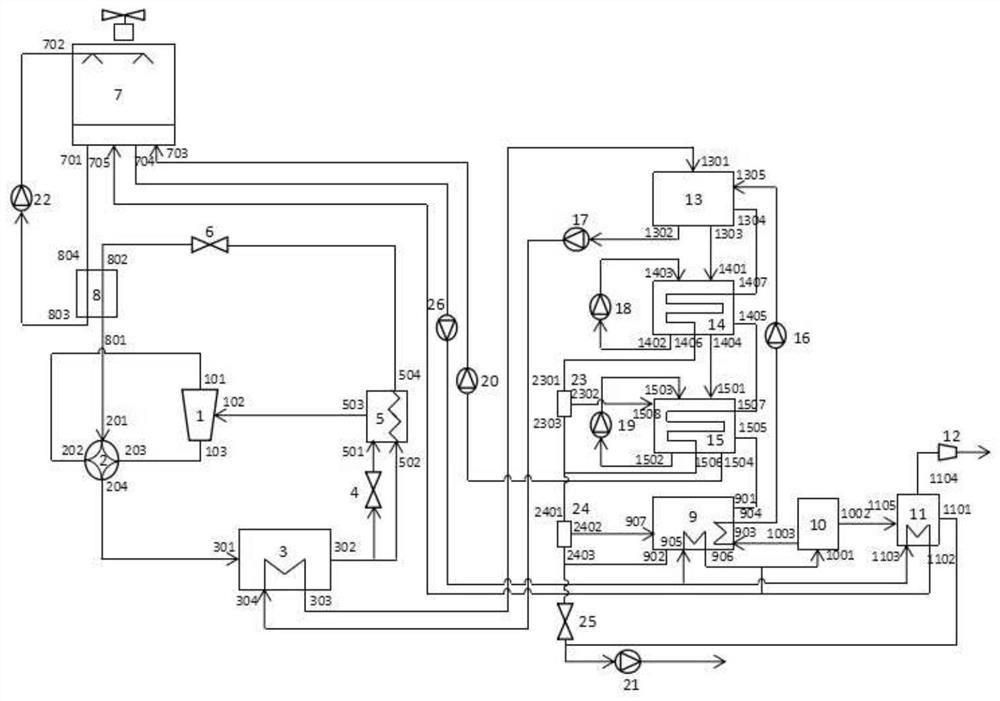

[0115] Embodiment 2, the second form of the low-temperature frost-free heat pump system for exhaust sensible heat regeneration, such as figure 2 shown;

[0116] Embodiment 2 Compared with Embodiment 1, the intermediate effect device 23 is changed to an intermediate effect condensate flash chamber; the final effect device 24 is changed to a final effect condensate flash chamber, and the rest is the same as in Embodiment 1.

[0117] The intermediate effect evaporation chamber 14 is connected to the condensate pump 21 after passing through the intermediate effect device 23 and the final effect device 24. The final effect evaporation chamber 15 is connected to the condensate pump 21 after passing through the final effect device 24. The intermediate effect device 23 is connected to the intermediate effect evaporation chamber 14 is connected; the final effect device 24 is connected with the final effect evaporation chamber 15.

[0118] The sixth inlet and outlet 1406 of the interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com