Industrial ultrafiltration membrane device pollutant online extraction and analysis method

A technology for ultrafiltration membranes and pollutants, which is applied in the direction of sampling devices, permeation/dialysis water/sewage treatment, etc., can solve the problem that technical information cannot quickly obtain pollutants, etc., and achieves good industrial application and promotion, simple extraction methods, and pollutants The real effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

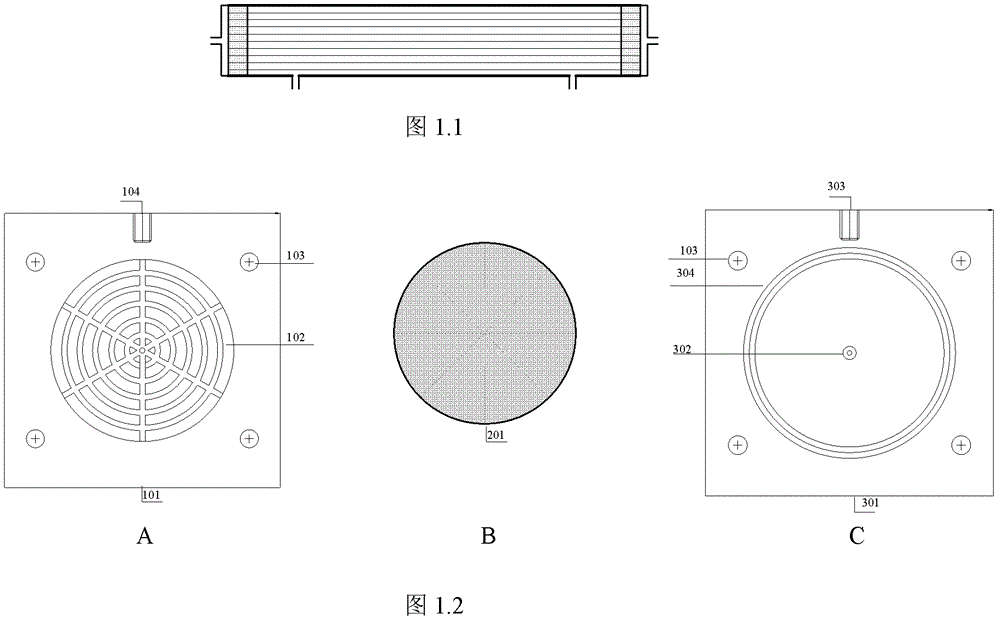

[0037] Concrete implementation steps of an industrial ultrafiltration membrane device pollutant online extraction, analysis and application method:

[0038] (1) Use 150 polyvinylidene fluoride hollow fiber ultrafiltration membranes with a length of 50 cm, a pore size of 0.02 μm, and a dense skin structure to prepare side line components for key pollutant extraction;

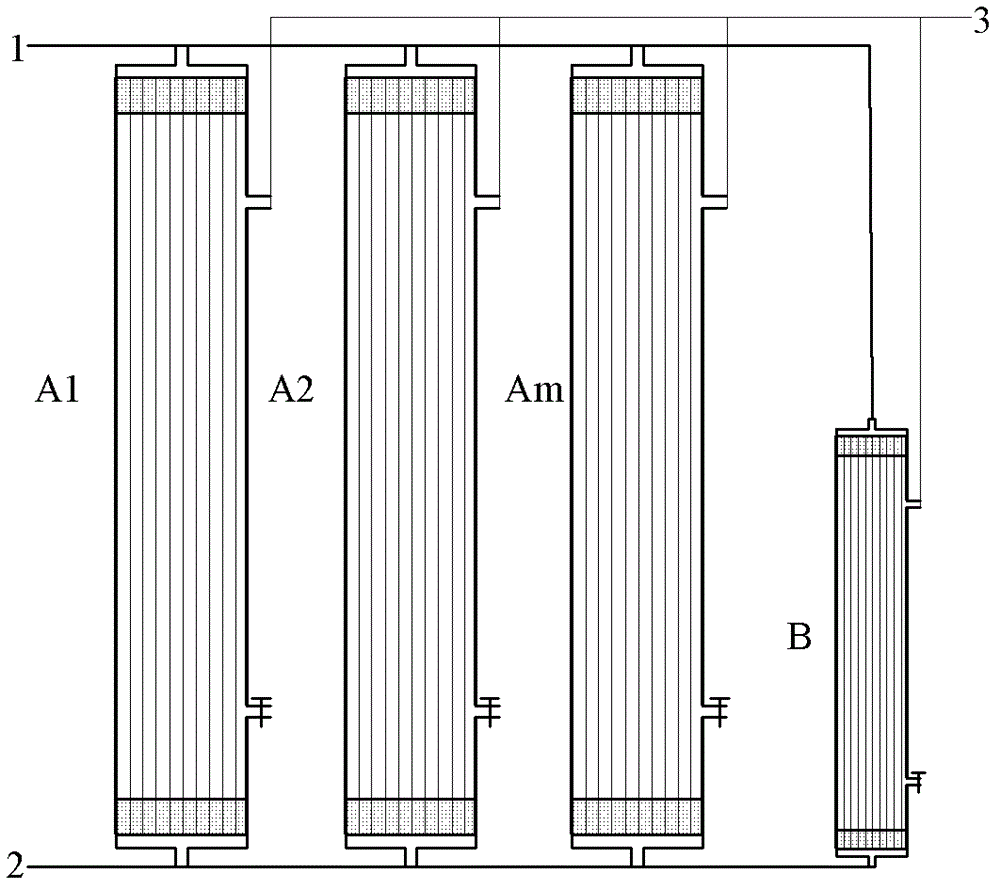

[0039] (2) Connect the influent, concentrated water and product water of the side line module prepared in step 1 to the industrial ultrafiltration membrane in parallel in the same way as the influent, concentrated water and product water of the membrane module in the industrial ultrafiltration membrane In the device, adjust the opening of the concentrated water discharge valve of the side line assembly, and adjust the flow velocity of the ultrafiltration water in the side line assembly to 2m / s;

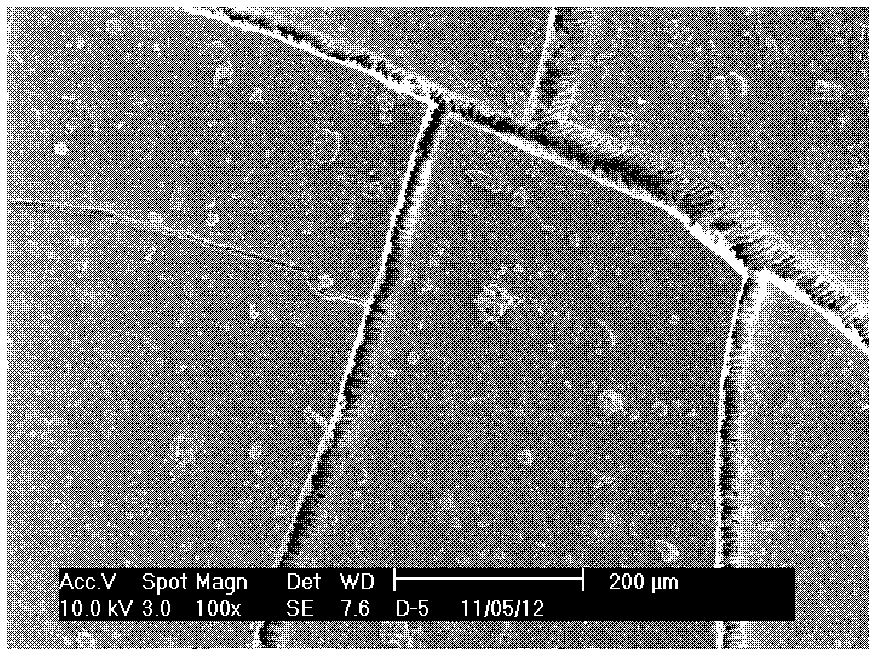

[0040] (3) Record the initial water production from the water production of the side line components, and record the w...

Embodiment 2

[0047] Concrete implementation steps of an industrial ultrafiltration membrane device pollutant online extraction, analysis and application method:

[0048] (1) Use 150 polyethersulfone hollow fiber ultrafiltration membranes with a length of 50 cm, a pore size of 0.05 μm, and a dense inner skin structure to prepare side line components for the extraction of key pollutants;

[0049] (2) Connect the influent, concentrated water and product water of the side line module prepared in step 1 to the industrial ultrafiltration membrane in parallel in the same way as the influent, concentrated water and product water of the membrane module in the industrial ultrafiltration membrane In the device, adjust the opening of the concentrated water discharge valve of the side line assembly, and adjust the flow velocity of the ultrafiltration water in the side line assembly to 4m / s;

[0050] (3) Record the initial water production from the water production of the side line components, and recor...

Embodiment 3

[0055] Concrete implementation steps of an industrial ultrafiltration membrane device pollutant online extraction, analysis and application method:

[0056] (1) Use 150 polyvinylidene fluoride hollow fiber ultrafiltration membranes with a length of 50 cm, a pore size of 0.05 μm, and a dense inner and outer skin structure to prepare side line components for the extraction of key pollutants;

[0057] (2) Connect the influent, concentrated water and product water of the side line module prepared in step (1) in parallel to the industrial ultrafiltration membrane module in parallel in the same way as the influent, concentrated water and product water of the membrane module in the industrial ultrafiltration membrane. In the membrane filter device, adjust the opening of the concentrated water discharge valve of the side line assembly, and adjust the flow velocity of the ultrafiltration water in the side line assembly to 6m / s;

[0058] (3) Record the initial water production volume fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com