Abrasion-resistant alloy cast iron material with high hardness for chute lining plate, and preparation method thereof

A wear-resistant alloy, high-hardness technology, applied in the field of metal wear-resistant materials, can solve the problem of not being able to meet high hardness and high impact toughness at the same time, and achieve the effects of increasing hardness, enhancing stability, and improving red hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

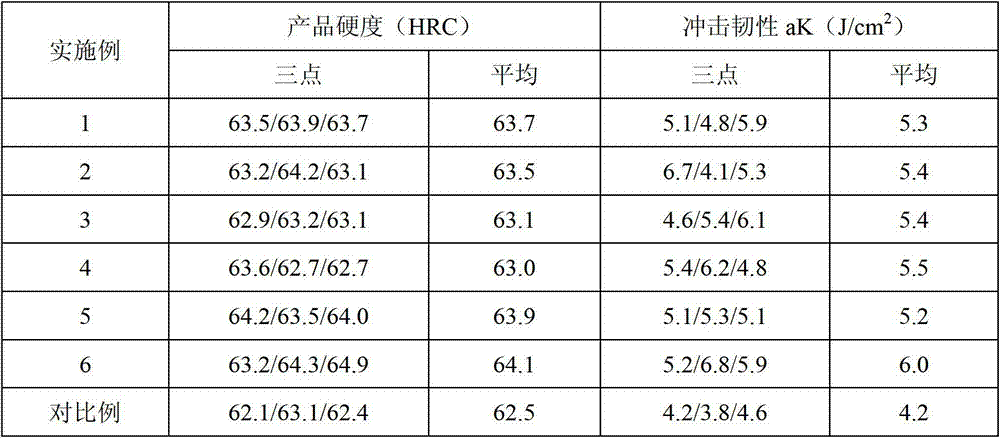

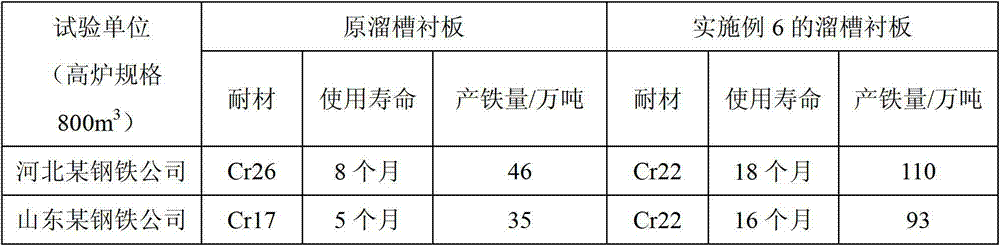

Examples

Embodiment 1

[0034] The high-hardness wear-resistant alloy cast iron material used for the chute liner of this embodiment consists of the following chemical components in mass fractions: C2.7%, Si0.4%, Mn0.9%, Cr21.5%, Mo1.0%, Cu1.1%, W0.6%, V0.2%, Ti0.07%, B0.001%, RE0.05%, Y0.05%, Al0.07%, S≤0.06%, P≤0.06%, The rest is Fe.

[0035] The preparation method of the high-hardness wear-resistant alloy cast iron material for the chute liner of the present embodiment comprises the following steps:

[0036] 1) Add scrap steel, ferrochrome, ferromolybdenum, ferrotungsten, scrap brass, ferromanganese, ferrovanadium, ferrotitanium and ferroboron to the melting furnace in sequence according to the formula to melt into molten iron at a melting temperature of 1520°C;

[0037] 2) Add rare earth silicon with a particle size of 5mm to the molten iron according to the formula for one-time modification treatment. When the temperature measured by the thermometer is 1520-1560°C, pour out the molten iron;

...

Embodiment 2

[0041] The high-hardness wear-resistant alloy cast iron material used for the chute liner of this embodiment consists of the following chemical components in mass fractions: C2.6%, Si0.65%, Mn1.0%, Cr22.5%, Mo1.1%, Cu1.0%, W0.8%, V0.1%, Ti0.09%B0.003%, RE0.07%, Y0.07%, Al0.04%, S≤0.06%, P≤0.06%, the rest For Fe.

[0042] The preparation method of the high-hardness wear-resistant alloy cast iron material for the chute liner of the present embodiment comprises the following steps:

[0043] 1) Add steel scrap, ferrochrome, ferromolybdenum, ferrotungsten, scrap brass, ferromanganese, ferrovanadium, ferrotitanium and ferroboron to the melting furnace in sequence according to the recipe amount to melt into molten iron at a melting temperature of 1540°C;

[0044] 2) Add rare earth silicon with a particle size of 8mm to the molten iron according to the formula for one-time modification treatment. When the temperature measured by the thermometer is 1520-1560°C, pour out the molten iro...

Embodiment 3

[0048] The high-hardness wear-resistant alloy cast iron material used for the chute liner of this embodiment consists of the following chemical components in mass fractions: C3.0%, Si1.0%, Mn0.75%, Cr23%, Mo1.2%, Cu0. 8%, W0.75%, V0.19%, Ti0.12%, B0.0028%, RE0.04%, Y0.04%, Al0.08%, S≤0.06%, P≤0.06%, the rest are Fe.

[0049] The preparation method of the high-hardness wear-resistant alloy cast iron material for the chute liner of the present embodiment comprises the following steps:

[0050] 1) Add steel scrap, ferrochrome, ferromolybdenum, ferrotungsten, scrap brass, ferromanganese, ferrovanadium, ferrotitanium and ferroboron to the melting furnace in sequence according to the formula to melt into molten iron, and the melting temperature is 1560°C;

[0051] 2) Add rare earth silicon with a particle size of 6mm to the molten iron according to the formula for one-time modification treatment. When the temperature measured by the thermometer is 1520-1560°C, pour out the molten i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com