Concrete vertical conveying pouring system

A vertical transportation and concrete technology, applied in construction, infrastructure engineering and other directions, can solve the problems of aggregate separation, difficult pipe dismantling, long time, etc., and achieve the effect of shortening construction period, reducing construction cost and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

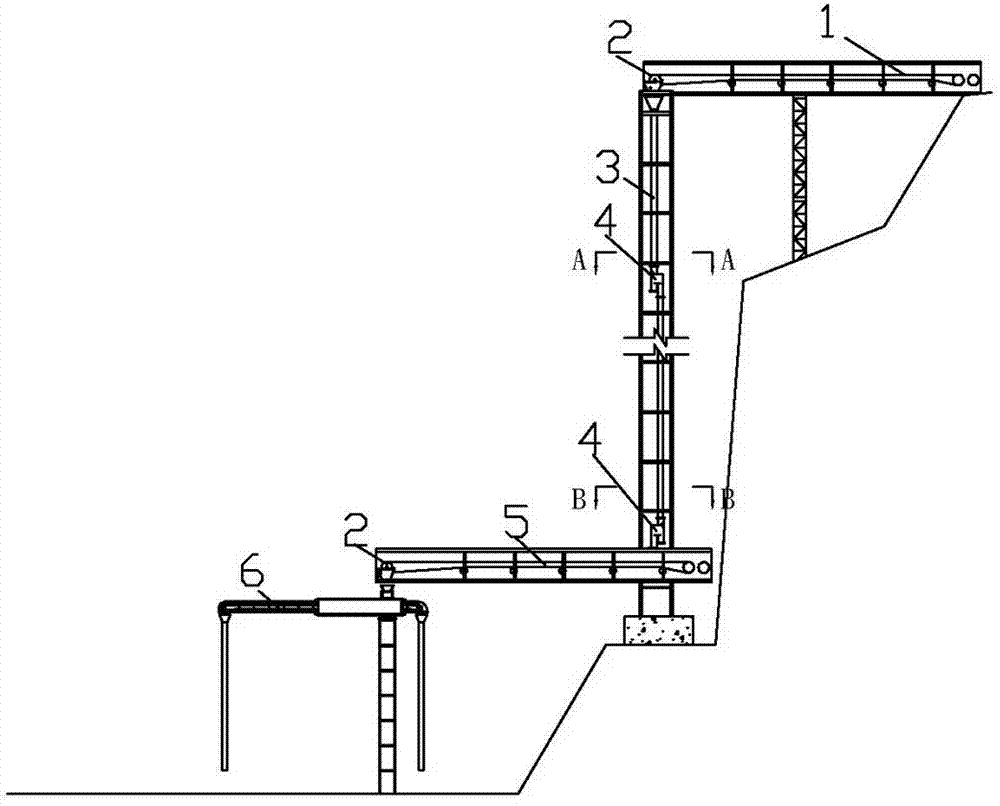

[0033] see Figure 1 to Figure 10 , the first belt conveyor 1 is erected next to the construction road for horizontal transportation, the output end is placed above the upper inlet of the vertically placed box pipe, the concrete is transported vertically through the vertically arranged box pipe 3, and the second belt is erected at the lower end of the box pipe 3 The machine 5 conveys the concrete to the concrete distribution machine 6, and the second belt conveyor 5 is placed on the top of the concrete distribution machine 6 in a horizontal position of 360 0 The elephant trunk slide pipe of diameter 420mm hangs at 6 two ends of the concrete distributing machine that rotates and carries out storehouse surface distributing.

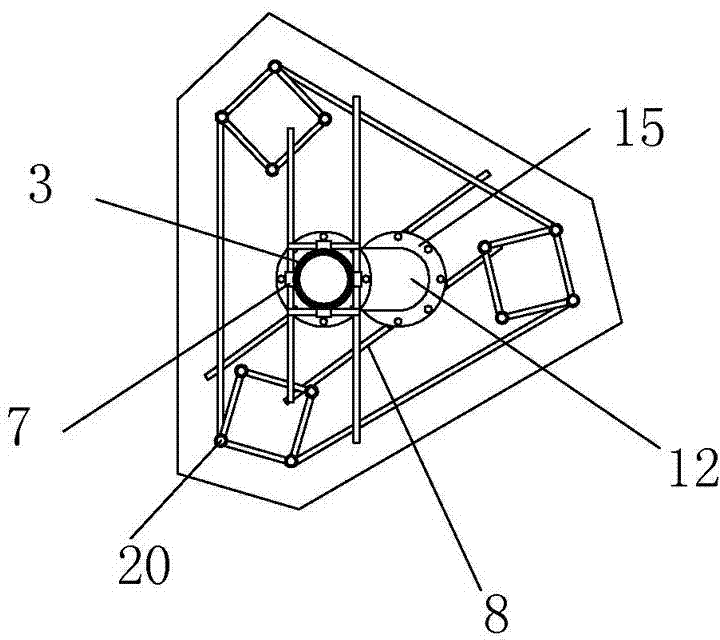

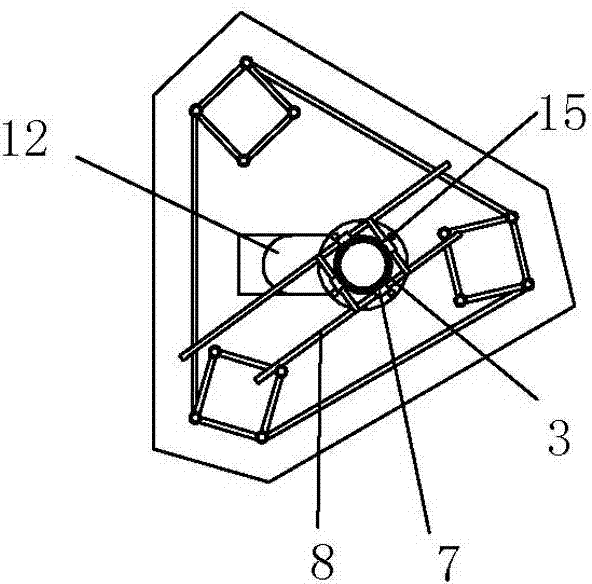

[0034] The Box pipe 3 has a single section length of 6m and a wall thickness of 10mm, and is installed on an equilateral triangular support composed of three steel cylinders 20 with a side length of 1.0m. The lower part of the bracket is fixed with C25 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com