Channelized LED (light-emitting diode) lamp

An LED lamp and channel-type technology, which is applied in the cooling/heating device of lighting devices, lighting devices, light sources, etc., can solve the problems of heat dissipation of LED lights, the heat dissipation effect of dust accumulation in the heat sink, and the high cost of waste of aluminum alloy materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

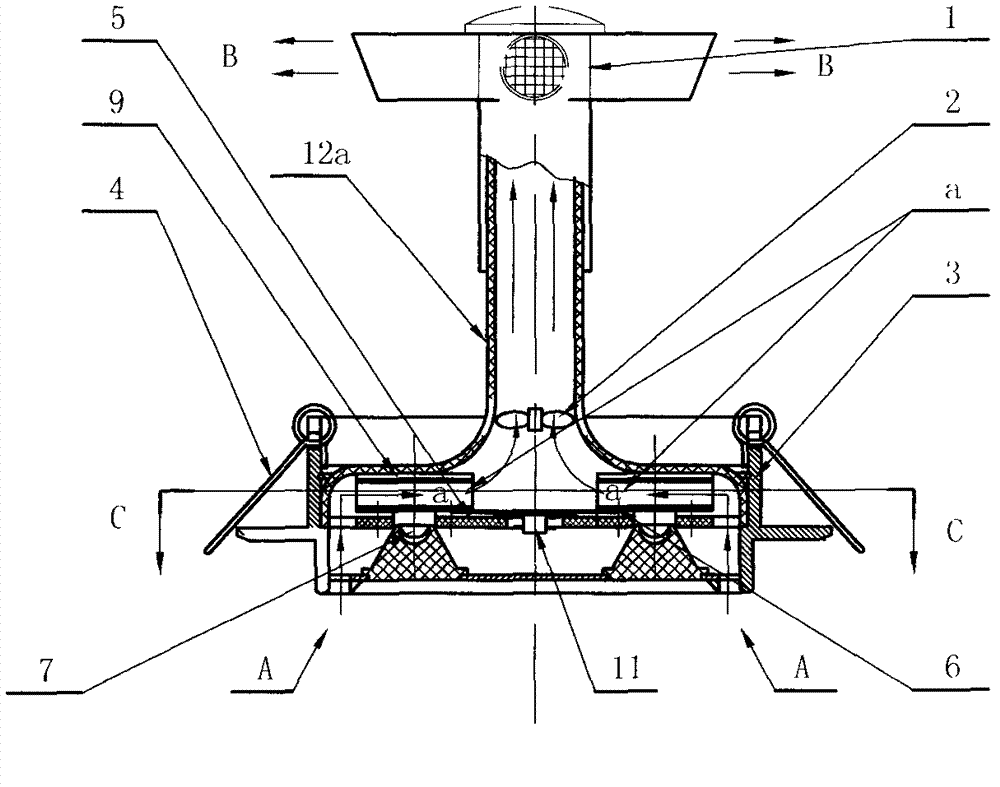

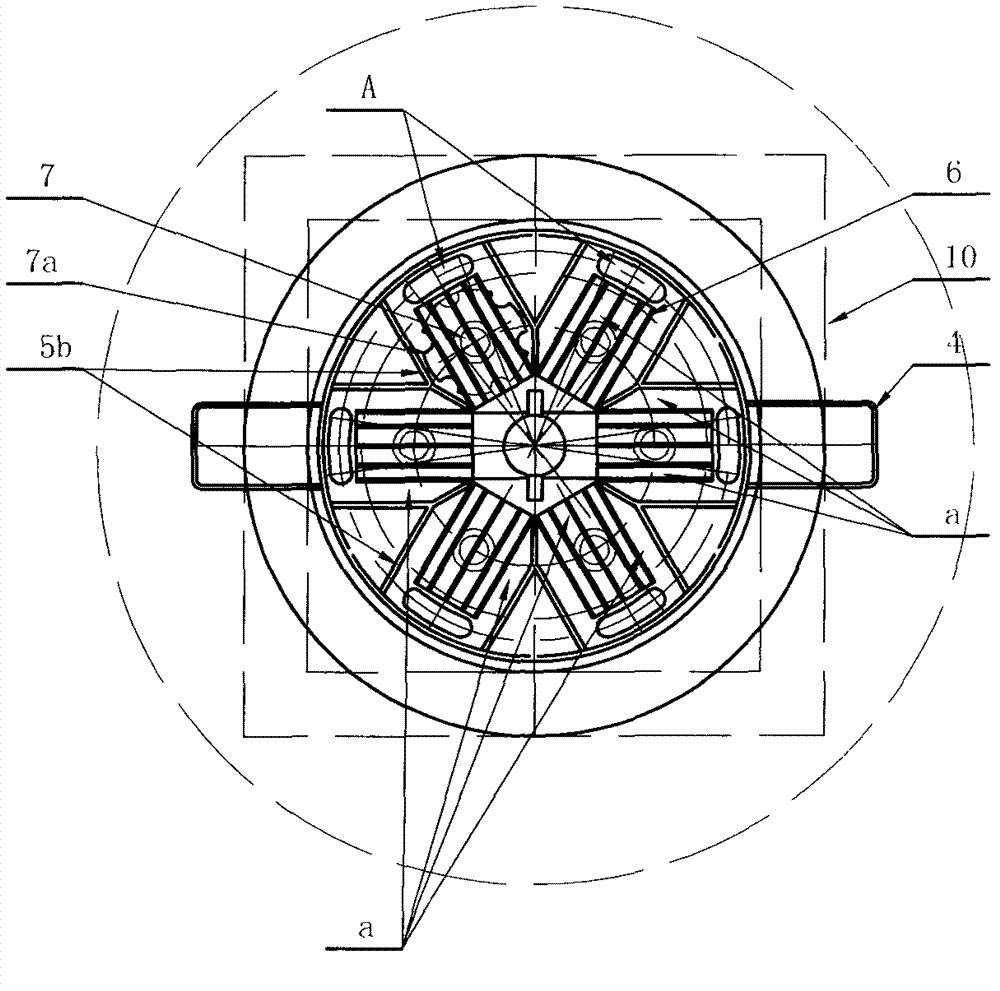

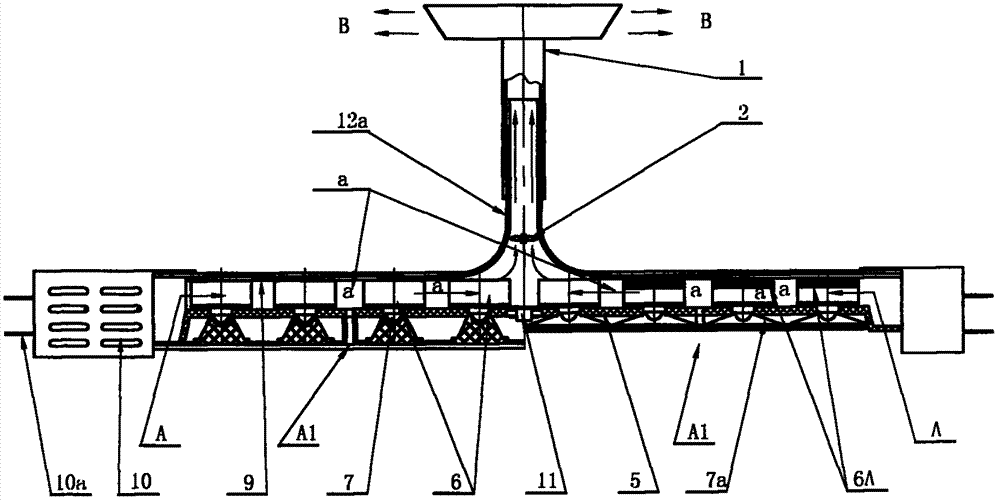

[0032] In order to further understand structure of the present invention, describe as follows with reference to accompanying drawing:

[0033] refer to figure 1 , 2 , is a channel-type LED lamp embodiment 1. It is a ceiling lamp. An inverted "T"-shaped middle air outlet 12a is installed in the lamp support 3. There are heat-conducting fins 6 on the left and right inside the lower part, and the lower part of the heat-conducting fin 6 is Adhering to the LED lamp chip 7, and fixedly connected with the support plate 5 through the screw holes on the heat conduction sheet 6, the heat conduction sheet 6 (group), the whole structure is reduced and distributed on the support plate 5, and the narrow channels of several airflow partition ribs 5a In a, the lower part of the left and right ends of the heat conduction sheet 6 (group) communicates with the air inlet A, and a T-shaped air outlet pipe 1 is installed in the middle air outlet 12a. , and according to the power of the LED lamp a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com