Detection method and detection device for impact energy of hydraulic breaking hammer

A technology of hydraulic breaker and detection method, which is applied in the direction of measuring device, force/torque/power measuring instrument, instrument, etc., which can solve the problem that the impact energy of hydraulic impactor cannot be accurately reflected, the piston weight of the piston action area is ignored, and the measurement result deviates from the real Value and other issues, to achieve the effect of facilitating use and maintenance, simple test method, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

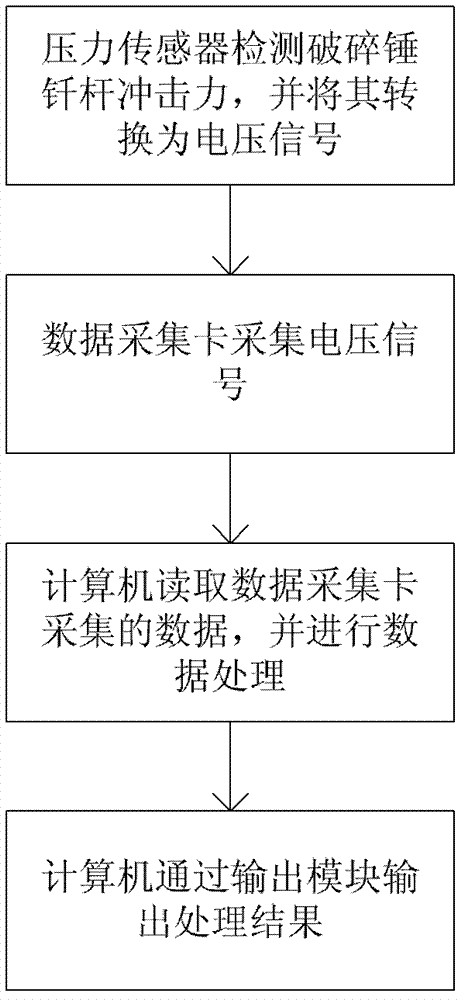

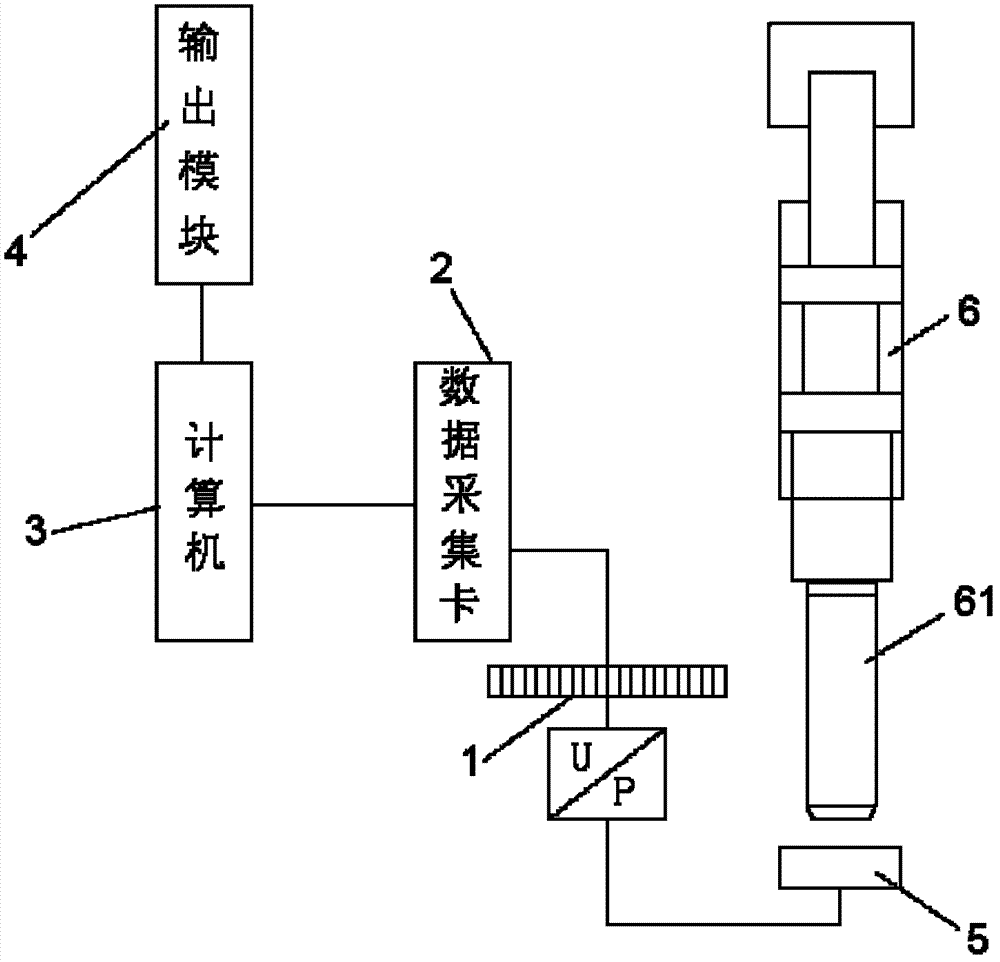

[0026] The flow process of detection method of the present invention is as figure 1 As shown, the impact force of the hammer drill rod is firstly detected by the pressure sensor 1 and converted into a voltage signal, and then the data acquisition card 2 collects the voltage signal at a certain period, and the computer 3 reads the data collected by the data acquisition card 2 and performs Through data processing, the impact performance parameters of the breaker 6 such as impact energy and impact frequency are obtained, and finally the processing results are output through the output module 4 .

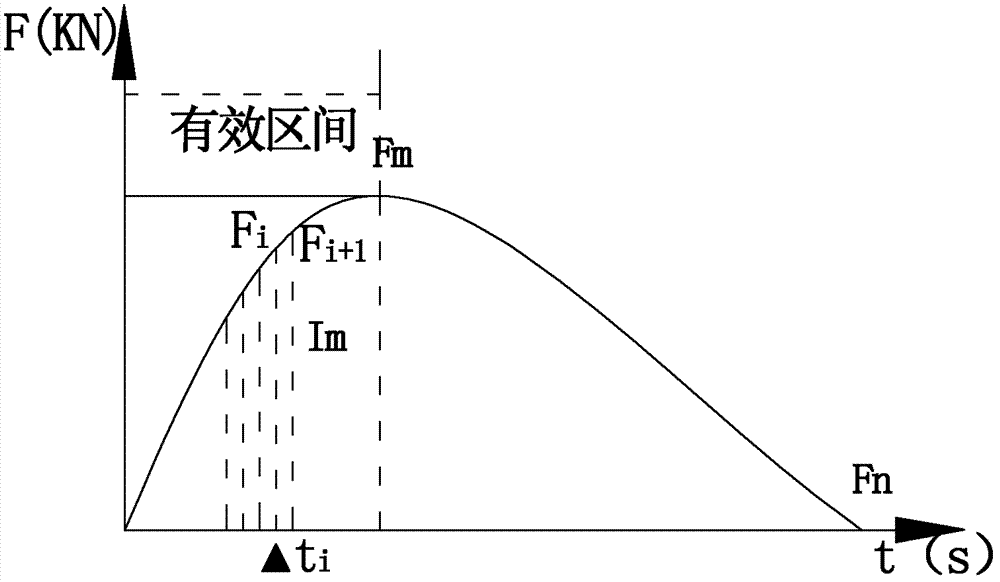

[0027] The data processing in the computer 3 includes the following steps: firstly, convert the data collected by the data acquisition card into the impact force according to the linear relationship, and obtain the action time data of the breaking hammer chisel; then, according to the measured impact force and the breaking hammer The impact time data of the drill rod is obtained from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com