Device for testing material burst at high temperature

A technology of high-temperature bursting and testing equipment, which is applied in the direction of measuring equipment, analyzing materials, and thermal analysis of materials, etc. It can solve problems such as unfavorable quantitative experiments, failure to observe test phenomena, and inability to monitor material temperature in real time, so as to achieve uniform and reliable temperature distribution. The effect of sexual enhancement and heat enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

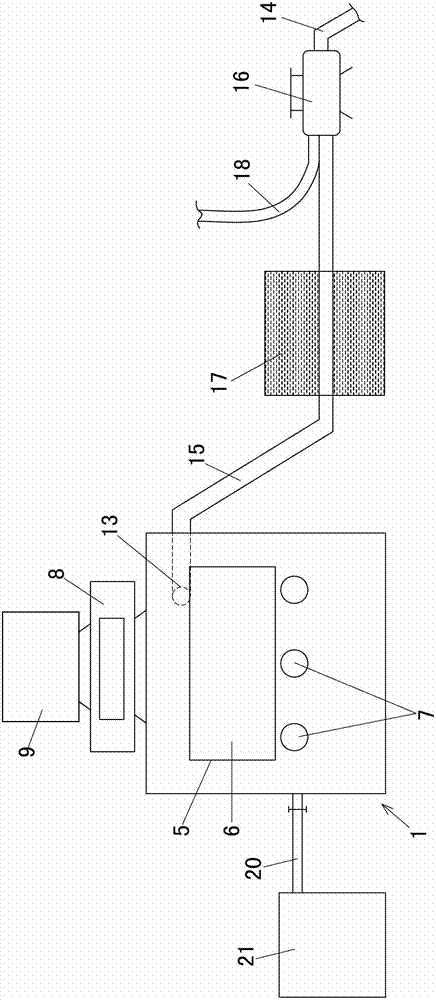

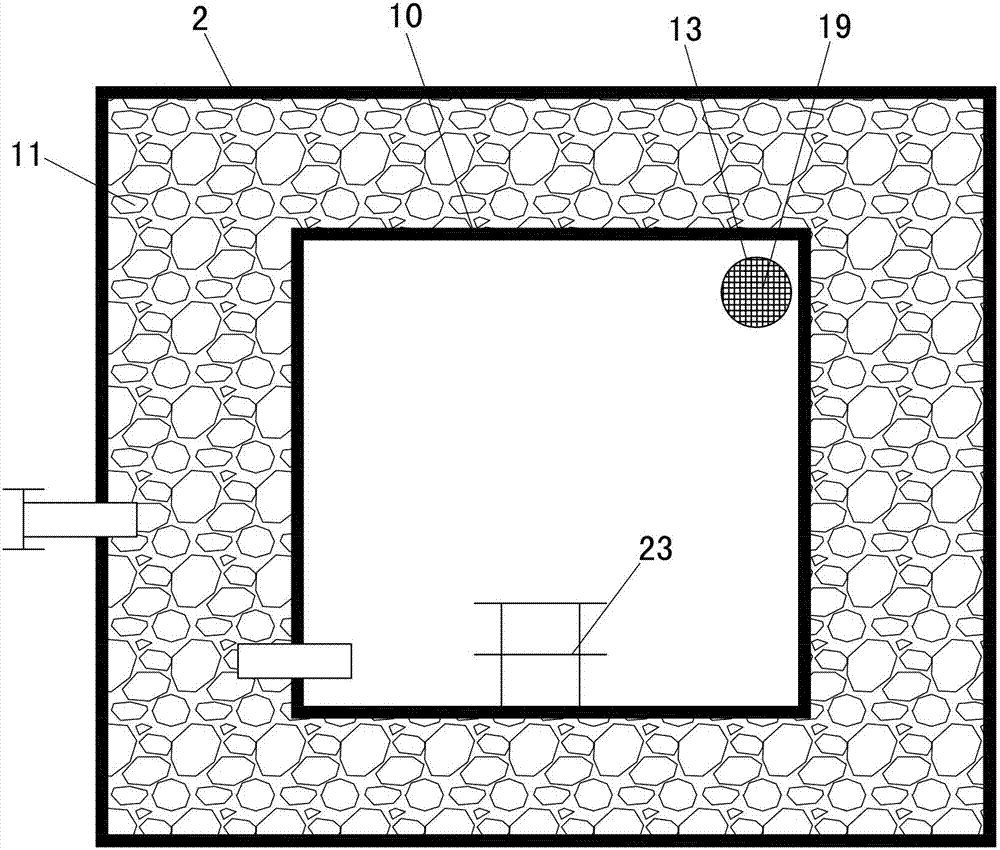

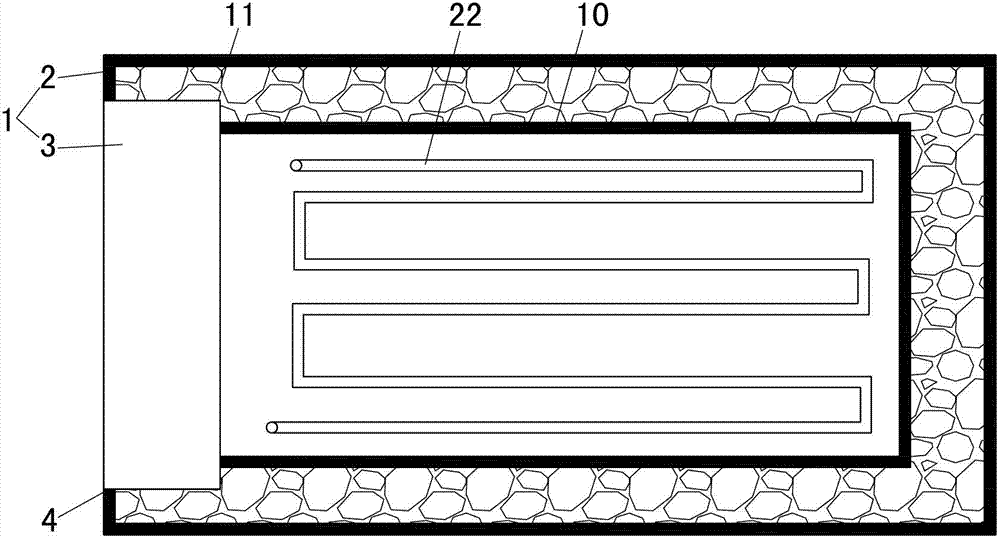

[0025] like Figure 1 to Figure 4 As shown, the material high-temperature burst test device of the present invention, a material high-temperature burst test device, includes a high-temperature resistance furnace 1 . A high temperature resistance furnace 1 includes a furnace body 2 and a furnace door 3 . The front plate of the furnace body 2 is processed with a rectangular first window 4 . The furnace door 3 is hinged on the front panel of the furnace body 2 through hinges. A rectangular second window 5 is processed on the furnace door 3 . A quartz glass plate 6 is mounted on the second window 5 . The first window 4 communicates with the second window 5 . The furnace door 3 is provided with three through holes 7 leading into the inner cavity of the furnace body 2 . A temperature inspection instrument 8 is placed above the furnace body 2 . The temperature inspection instrument 8 is connected with three temperature measuring sensors. Three temperature measuring sensors ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com