Self-adaptive tracking probe applied to ultrasonic scanning detection

An adaptive tracking and ultrasonic scanning technology, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as lack of attitude and distance adaptive capabilities, difficulty in implementation, and limitations in engineering application effectiveness. Achieve the effect of adaptive tracking ability and effect, improved adaptive tracking ability, and good adaptive climbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

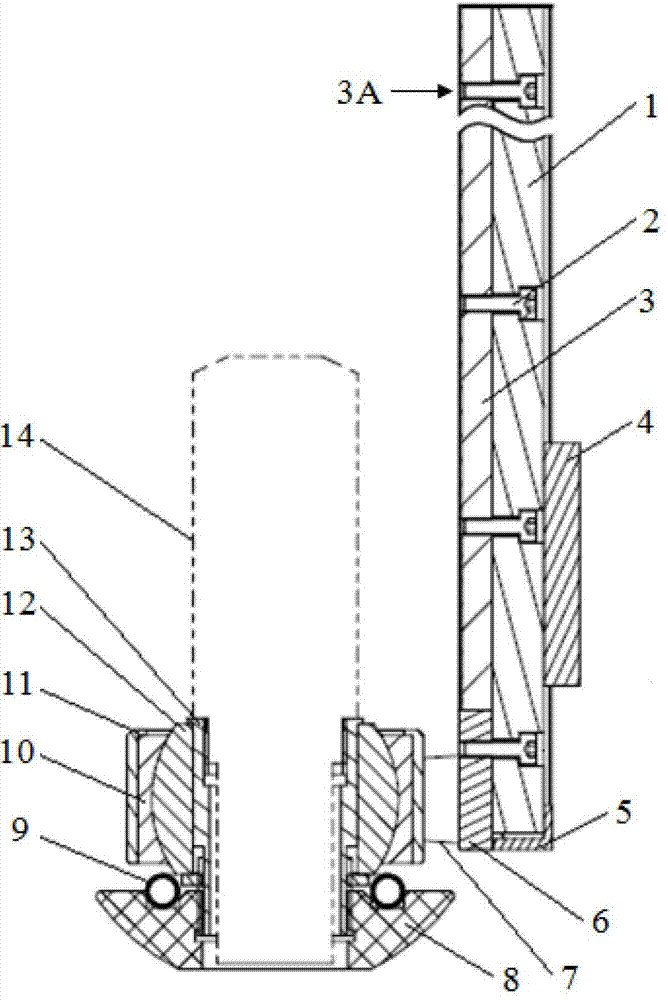

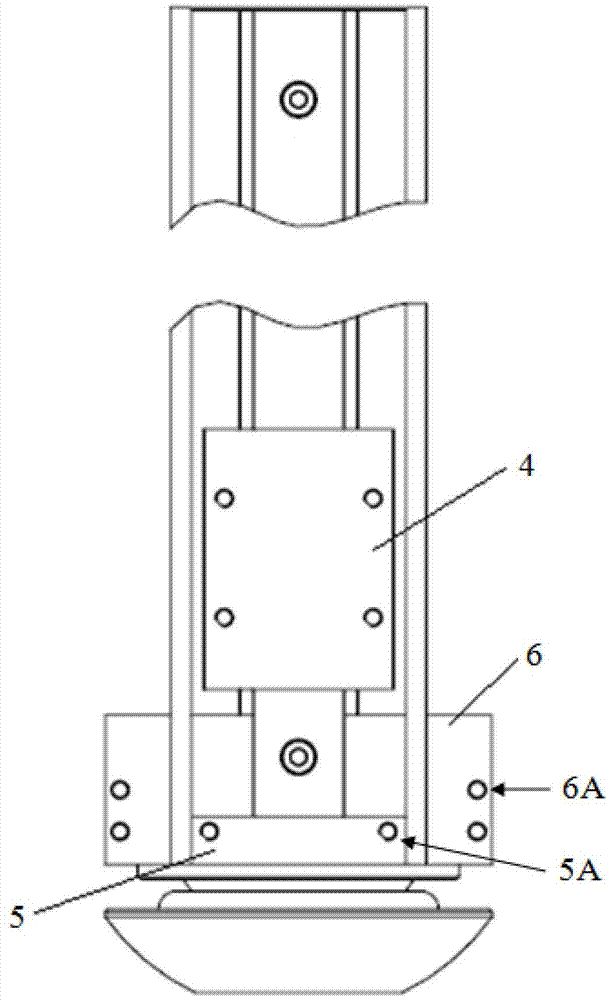

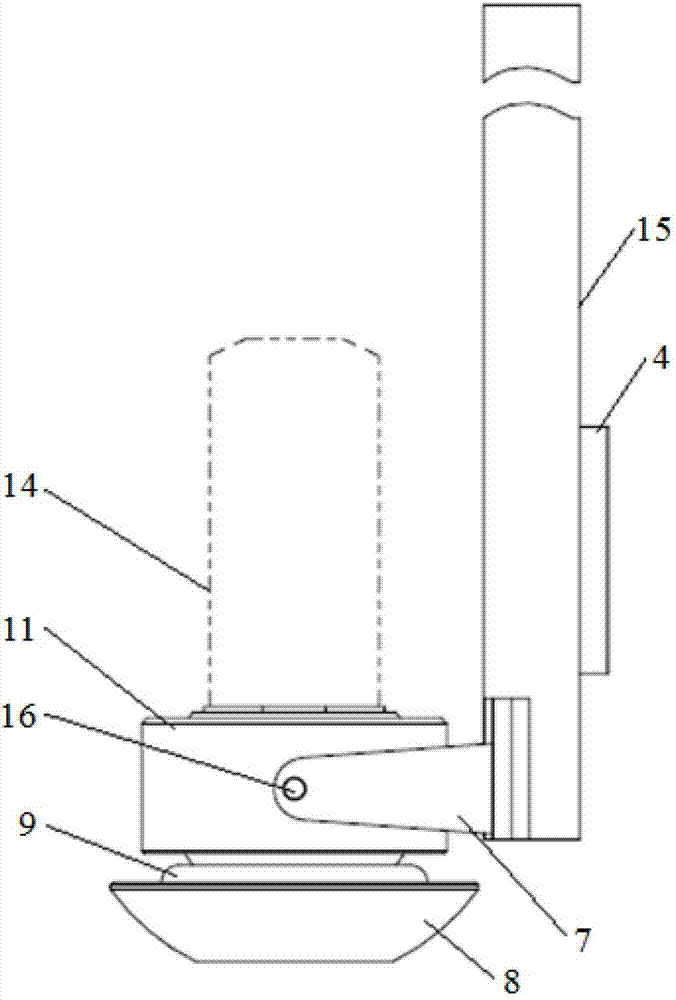

[0030] Using the self-adaptive tracking probe for ultrasonic scanning detection in the present invention, the CUS-6000 and CUS-21J series ultrasonic automatic testing equipment produced by Beijing Aeronautical Manufacturing Engineering Research Institute are used to match the self-adaptive tracking probe in the invention of this patent. , using the tracking method of the self-adaptive tracking probe of ultrasonic scanning detection in the present invention, a series of actual multi-curvature aircraft composite materials and metal parts with a length between 1000-6000mm and a chord height of 100mm and 200mm per meter have been carried out. Ultrasonic adaptive tracking scanning detection, during the automatic scanning process, the adaptive tracking probe always maintains flexible and good adaptive tracking and acoustic wave coupling with the surface of the part to be inspected with complex shapes, the detection signal display is very stable, and the adaptive tracking is stable and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com