Circuit for improving traveling wave tube amplifier filament service life

A traveling wave tube amplifier and filament voltage technology, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of traveling wave tube reliability, short slow start time, filament current impact, etc., to achieve strong product consistency, The circuit is simple and the effect of reducing the current impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

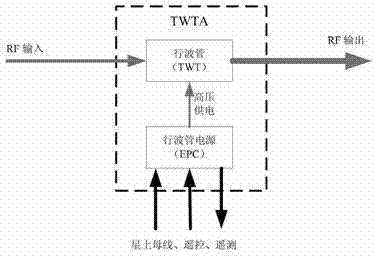

[0017] The schematic diagram of the circuit to improve the filament life of the traveling wave tube amplifier is as follows: figure 2 shown. The circuit includes: a filament isolation transformer T1, and a filament voltage regulation circuit (including a triode Q1, an operational amplifier N1, resistors R1, R2, R3, and a current limiting resistor R4). The filament isolation transformer T1 is composed of a primary winding and a secondary winding, the primary winding is composed of two windings, connected to the internal DC / AC circuit of the traveling wave tube power supply; the center tap is connected to the collector of the triode Q1, and the filament isolation transformer T1 The negative side winding of the TWT is connected to the filament load R5 of the traveling wave tube; the emitter of the triode Q1 is connected to the ground after the resistor R4 is connected in series; the reference voltage is connected to the same input terminal of the operational amplifier N1; one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com