Through-silicon via (TSV) testing structure and TSV testing method

A technology of testing structure and testing method, applied in electromagnetic measuring device, electrical/magnetic diameter measurement, electrical components, etc., can solve the problem of ineffective testing, and achieve the effect of accurate, sensitive, convenient and quick measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

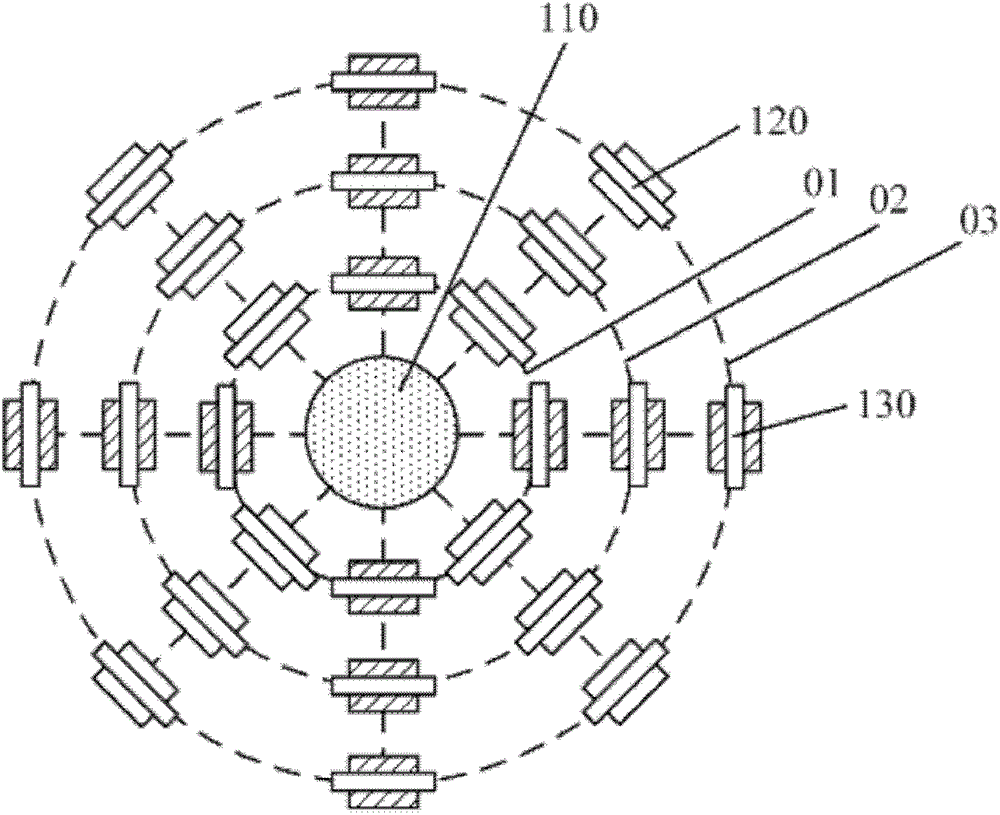

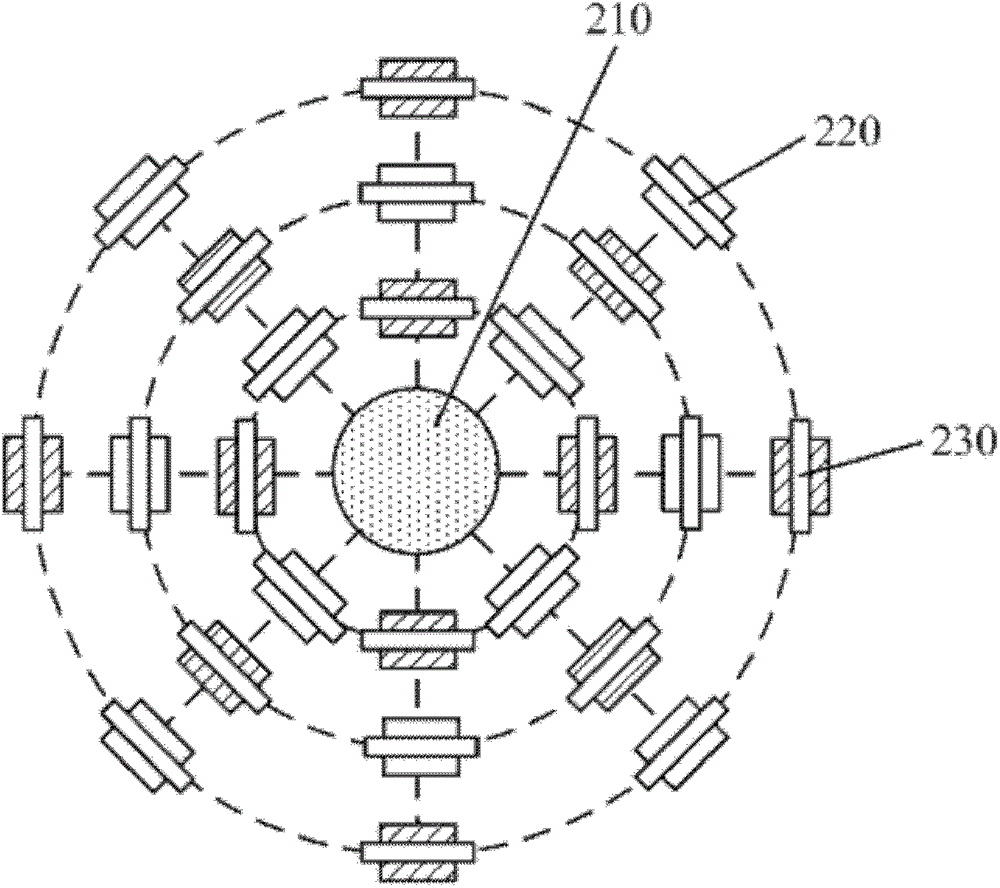

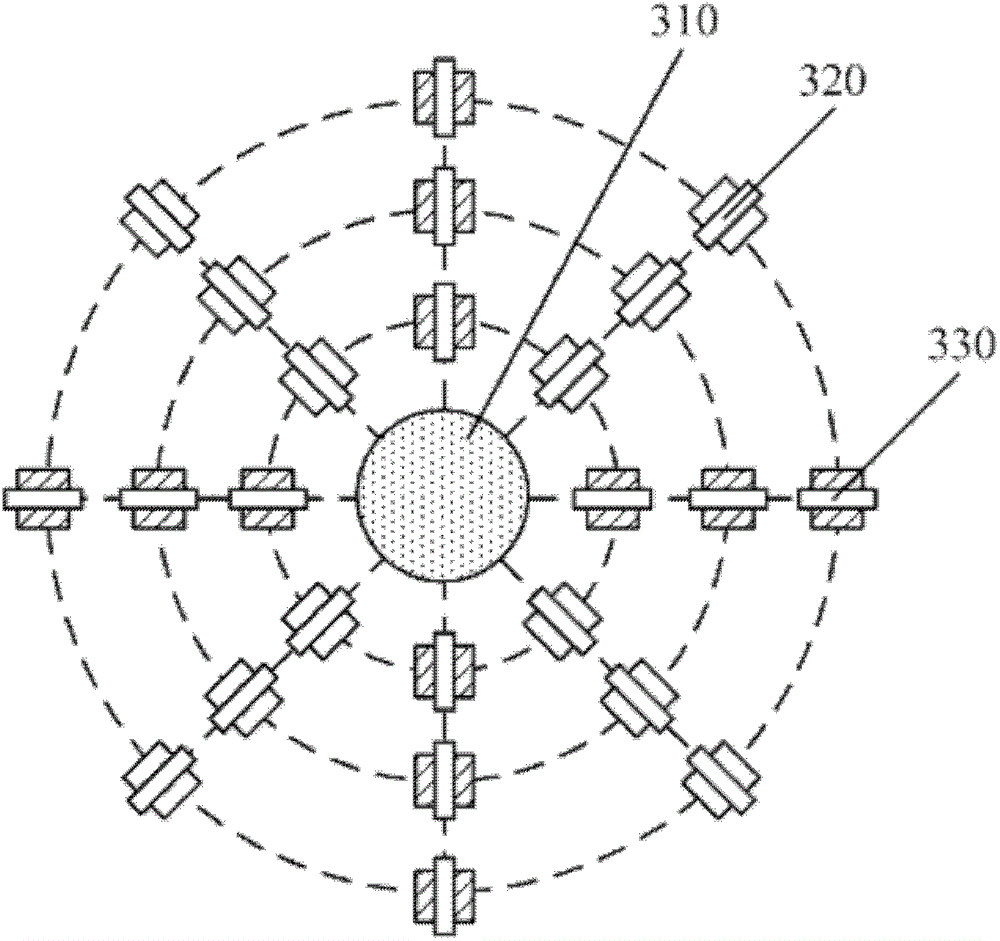

[0043] In the prior art, in order to realize three-dimensional stacking of chips, through-silicon vias penetrate the entire silicon substrate to realize the electrical connection between the upper and lower chips. Wherein, the TSV is filled with copper, and an isolation layer is formed between the copper and the silicon substrate to prevent copper from diffusing into the silicon substrate. However, when the temperature of the silicon substrate changes, due to the thermal expansion coefficient mismatch between the copper and the silicon substrate, it is easy to cause the TSV to generate tensile or compressive stress on the surrounding silicon substrate. The magnitude of the compressive stress is inversely proportional to the distance from the TSV, and the tensile or compressive stress changes the lattice constant of the channel region of the MOS transistor finally formed around the TSV, so that the current carrying The mobility of the electrons has changed, which affects the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com