Battery pack heat management device

A battery management unit, battery pack technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of inconsistent temperature, long heating time, small heat transfer coefficient, etc., to reduce the consumption of a lot of electric energy, shorten the Time required for heating, effect of solving heating and defrosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

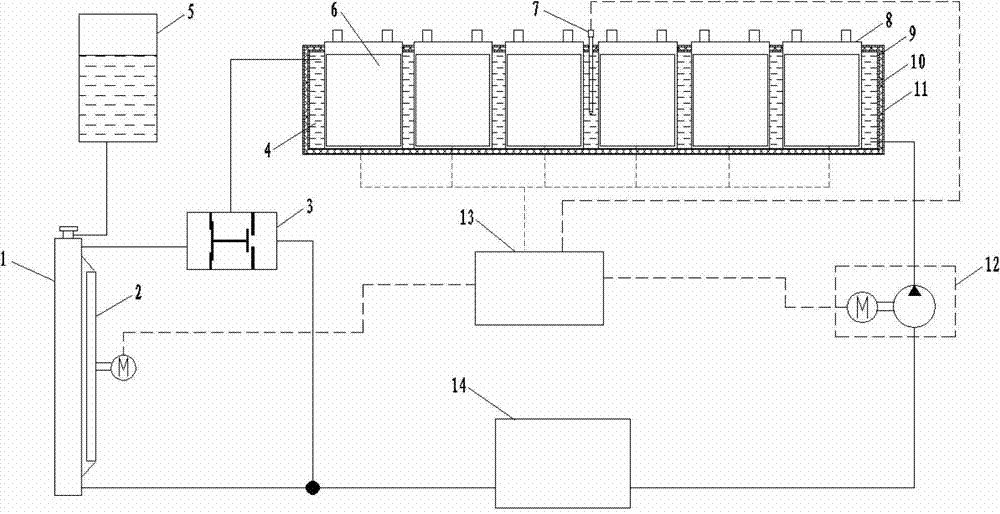

[0026] The present invention provides a thermal management device for a battery pack, such as figure 1 As shown, it mainly includes liquid cooling box 1, electronic fan 2, thermostat 3, liquid medium 4, auxiliary liquid tank 5, semiconductor and temperature sensor unit 6, battery box temperature sensor 7, battery cell 8, battery box inner shell 9. Battery box insulation layer 10 , battery box casing 11 , electric pump 12 , battery management unit 13 and heating module 14 .

[0027] Battery cells 8 are connected in series or in parallel to form a battery pack. The battery pack is the core component of the thermal management system of the battery pack. All other components serve the battery pack to ensure that the battery pack can work at the best performance. within the temperature range.

[0028] The battery box inner shell 9 , the battery box heat insulating layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com