Brushless DC Motor

A brushed DC motor and motor shaft technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as motors that are difficult to solve, and achieve the effects of smooth rotation, wide application range, and low noise decibels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The best embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

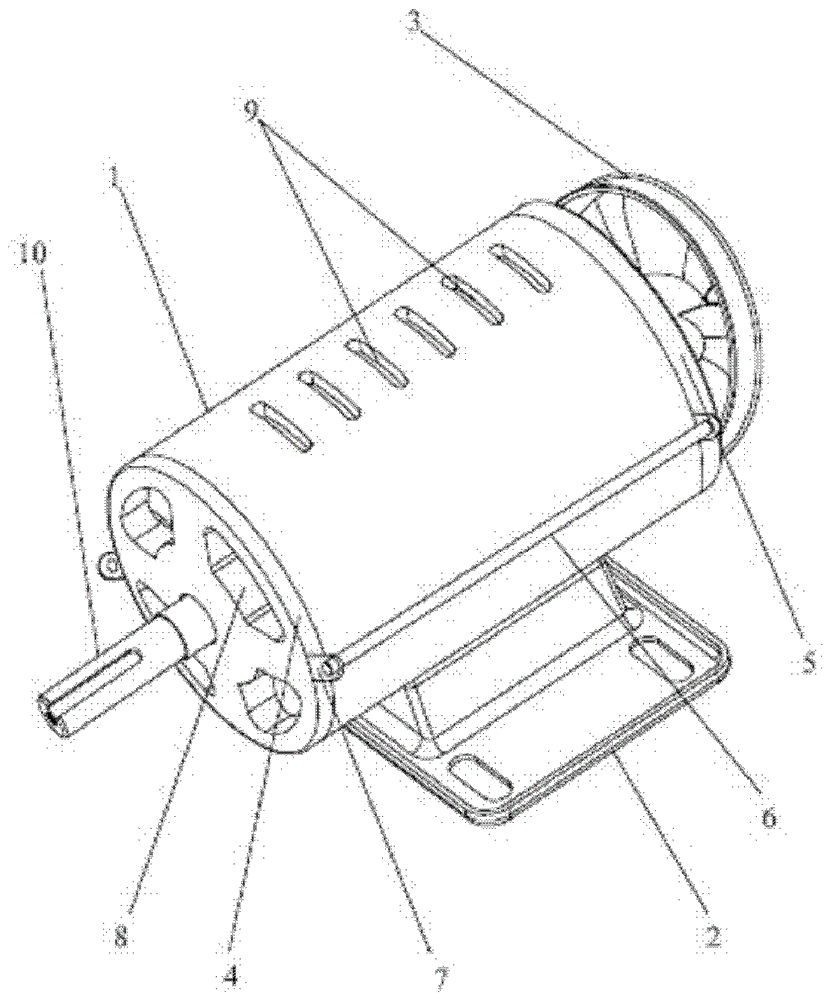

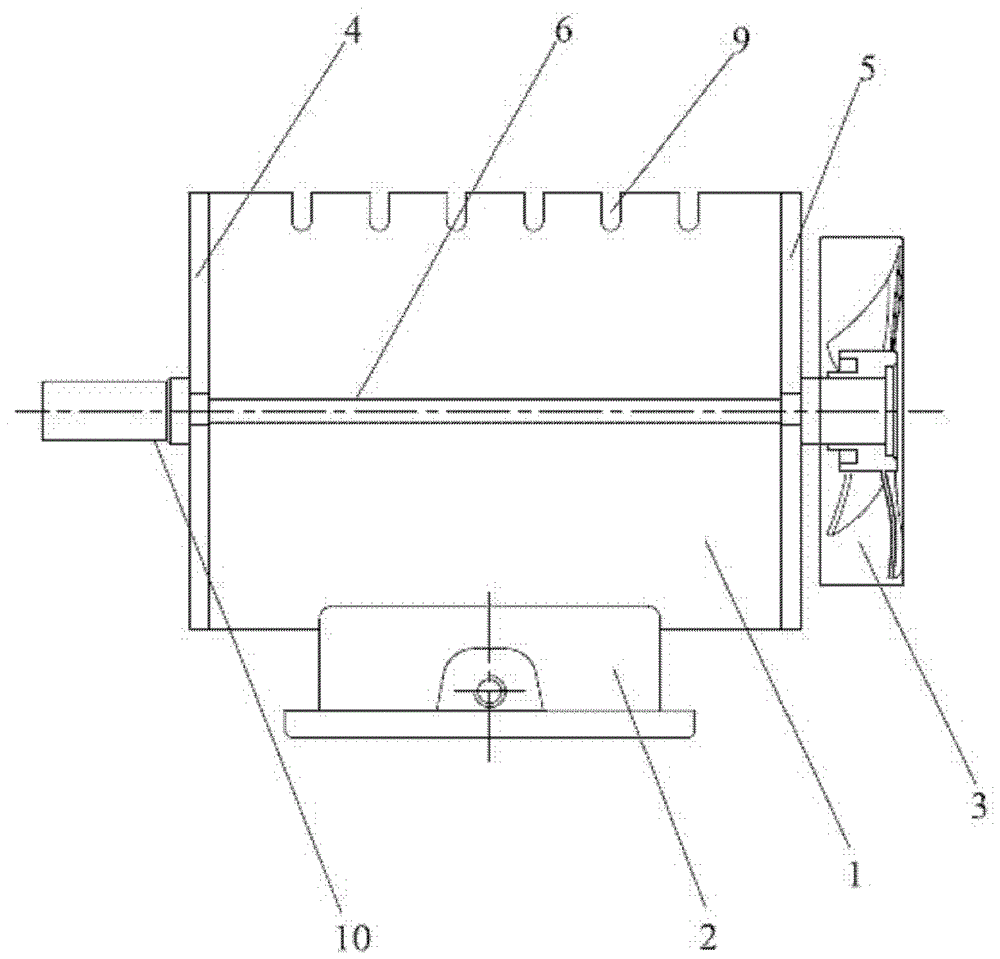

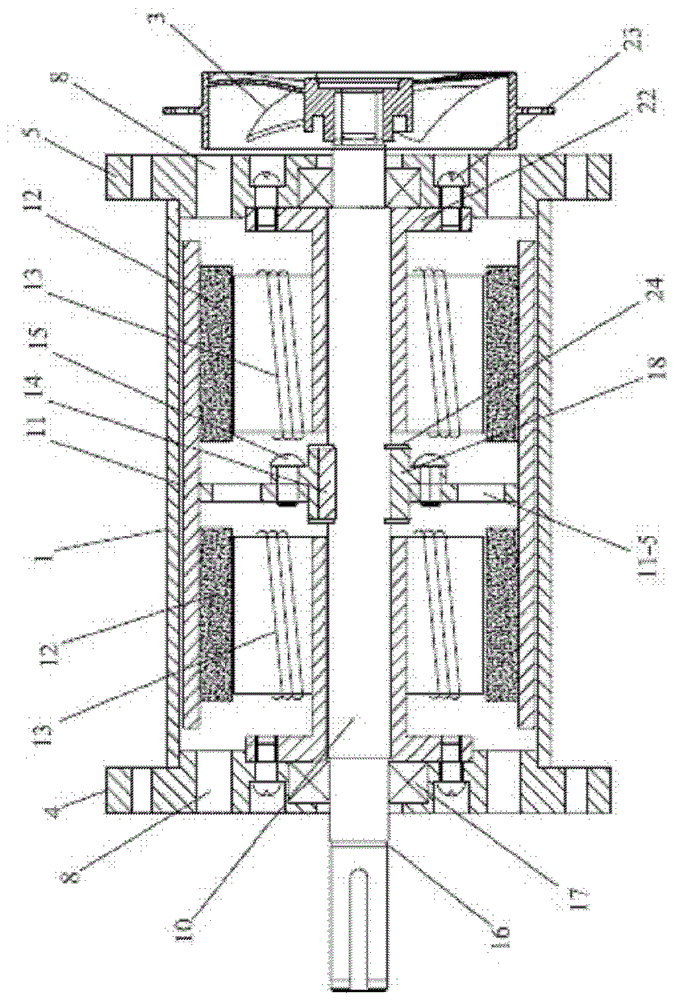

[0041] Such as Figure 1-3 As shown in and 8, the brushless DC motor described in the embodiment of the present invention includes a housing 1, a base 2, a fan 3, a front end cover 4, a rear end cover 5, a motor shaft 10, a rotor 11, a permanent magnet 12, and a stator 13, The shell 1 is a hollow cylinder structure, the front side of the shell 1 ferrules the front end cover 4, the rear side of the shell 1 ferrules the rear end cap 5, and the outer edges of the front end cap 4 and the rear end cap 5 are oppositely provided with connecting ears 7, The connecting ears 7 of the front end cover 4 and the rear end cover 5 are connected by the connecting rod 6, and the front end cover 4 and the rear end cover 5 are locked on both sides of the shell 1 by the connecting rod 6, which is convenient to use when landing. Ventilation holes 8 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com