Single-inductor intelligent photovoltaic module and control method and photovoltaic system based on single-inductor intelligent photovoltaic module

A photovoltaic module and control method technology, applied in the field of solar photovoltaic power generation research, can solve problems such as failure to reach the maximum output power point, poor system reliability, system oscillation, etc., and achieve the effect of eliminating energy loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

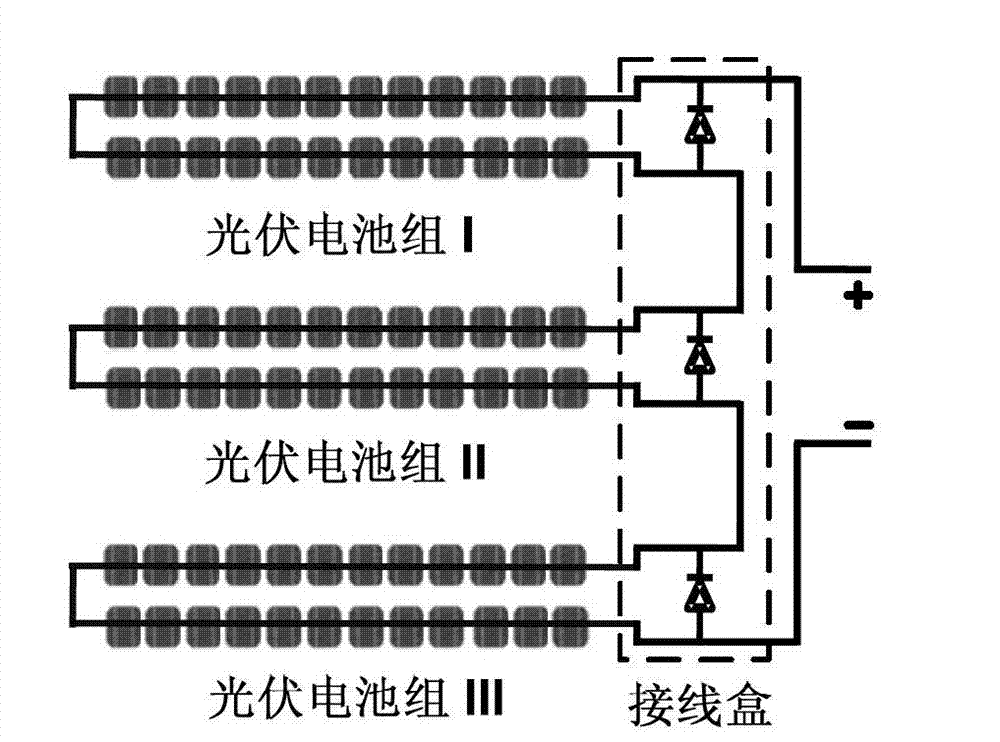

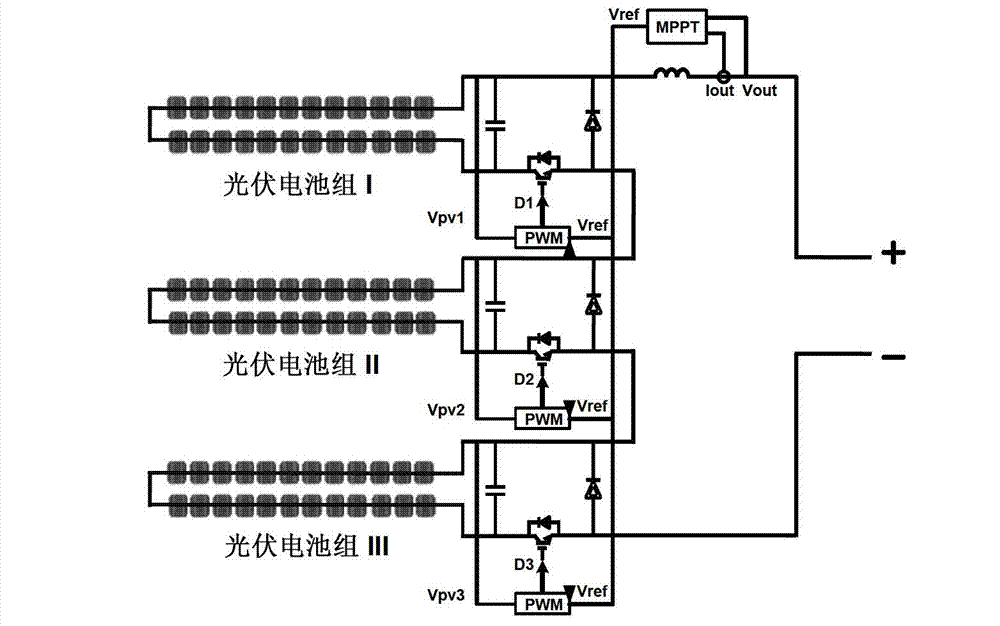

[0028] Conventional photovoltaic solar panels (see figure 1 The output of each photovoltaic cell group in ) is connected in series, so the output current must be consistent, and in the case of shading or uneven illumination, a "hot spot" phenomenon will occur, which will cause damage to the solar panel. Therefore, the common practice in the industry is to connect a diode in antiparallel to each photovoltaic cell group (see figure 2 ), through the bypass method to avoid damage to the battery pack due to inconsistent output current. This method prolongs the life of the solar panel to a certain extent, but also gives up the energy generated by the shaded battery pack, and also seriously affects the efficiency and stability of the solar system. The present invention proposes a photovoltaic module based on a distributed maximum power tracking structure, which uses multiple sets of power electronic switches, capacitors, and inductors to replace the parallel diodes in the junction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com