Injection and metering device

A technology of distributing device and injection position, applied in the direction of muffler device, exhaust device, exhaust gas treatment, etc., can solve the problems of expensive and expensive manufacturing, installation and maintenance, undefined opening behavior of the nozzle needle, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

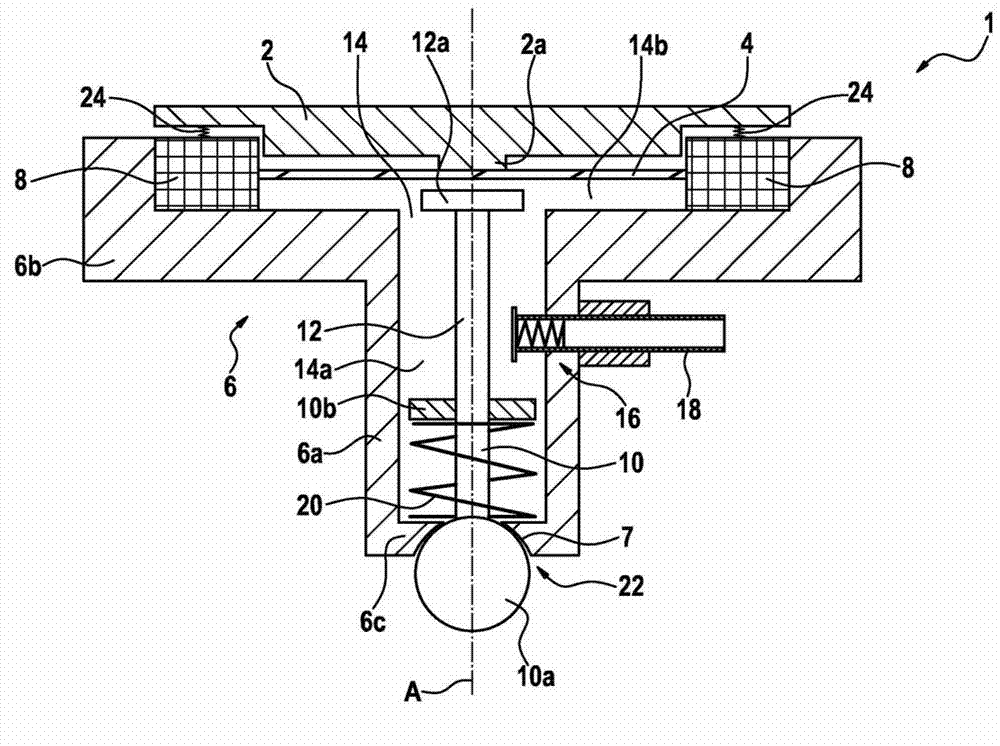

[0026] In the following description, descriptions such as "upper" and "lower" are used to better explain the schematic diagrams of the embodiments of the invention shown in the drawings, and cannot limit the invention to the shown embodiments or to certain Orientation or installation position.

[0027] The spray and metering device 1 has a substantially rotationally symmetrical holding body 6 about a longitudinal axis A, which has a lower holding body region 6a and an upper holding body region 6b. The lower holding body region 6a has a smaller cross section in a plane lying perpendicular to the longitudinal axis A than the upper holding body region 6b.

[0028] A pressure and injection chamber 14 is formed in the holding body 6 eg rotationally symmetrically about the longitudinal axis A, having an upper region 14b and a lower region 14a. The upper region 14b of the pressure and injection chamber 14 formed in the upper holder region 6b has a larger diameter in a plane arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com