Root-soil separating device for root crops

A technology of root-soil separation and rhizomes, which is applied in the direction of digging harvesters, agricultural machinery and implements, and applications, can solve the problems of separation of corn stubble and soil complexes, environmental pollution heat, single harvesting objects, etc., to reduce Root stubble harvesting cost, low labor intensity, and the effect of improving harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

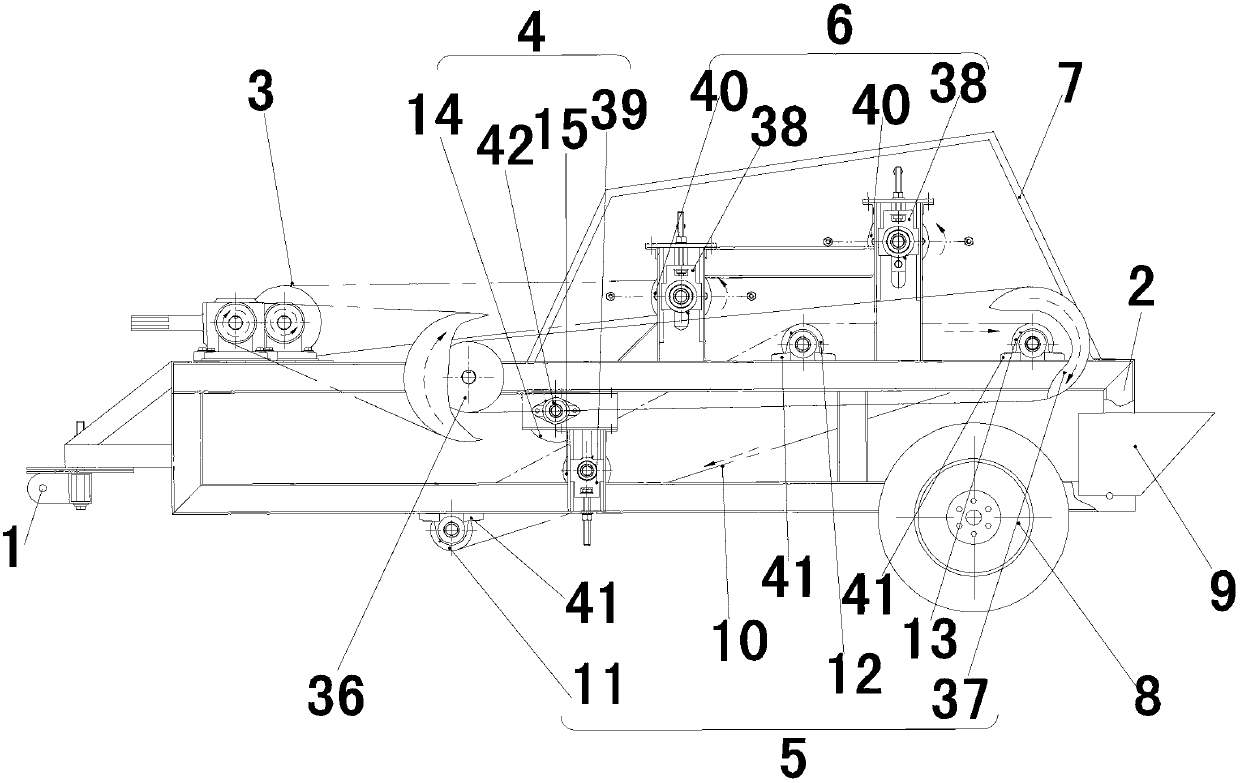

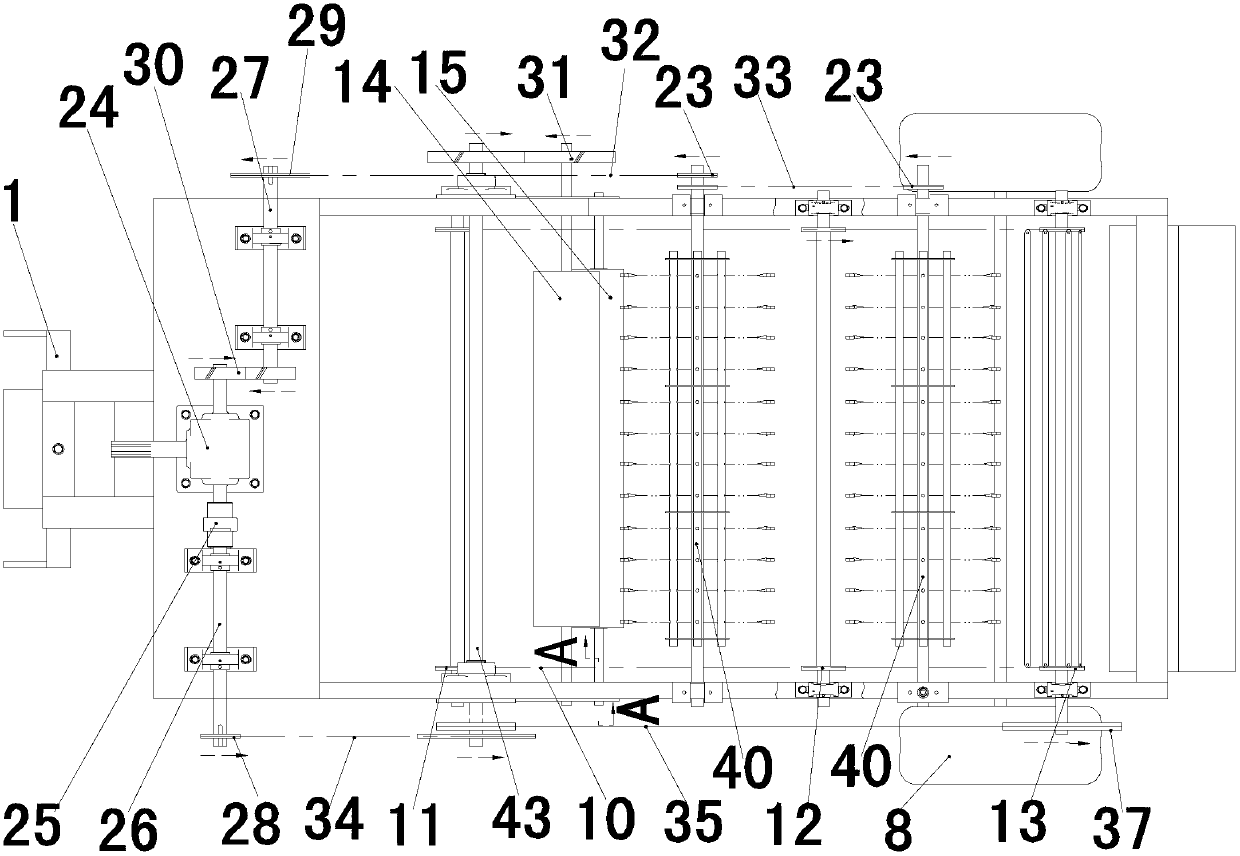

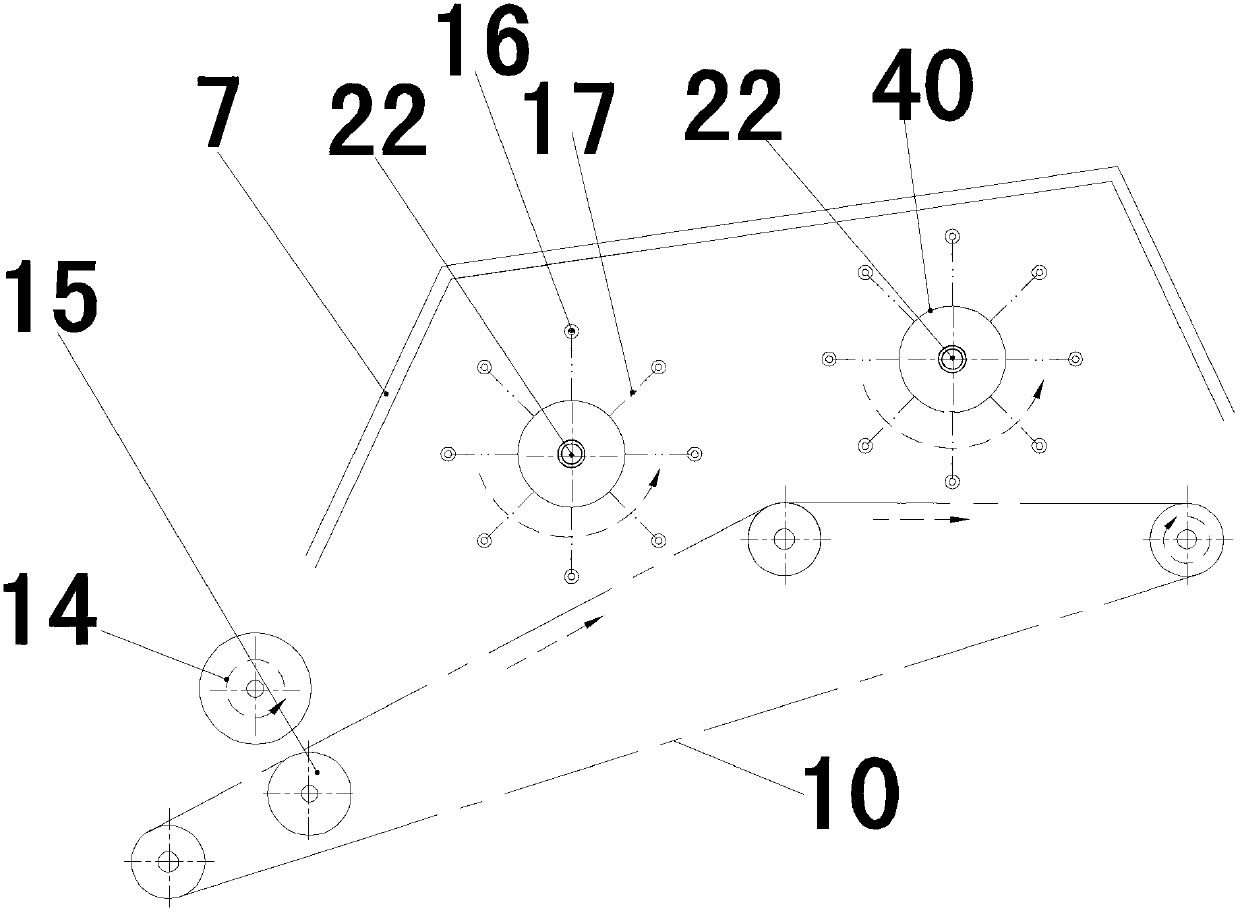

[0025] Such as Figure 1~6 As shown, a root-soil separation device for rhizome crops includes a traction frame 1, a frame 2, a transmission mechanism 3, a double-roller rolling mechanism 4, a rod chain conveying mechanism 5, a flexible connection fly hammer striking mechanism 6, a cover Plate 7, ground wheel 8 and stubble collecting box 9; Wherein, frame 2 front ends are provided with traction frame 1, and the rear end of frame 2 is provided with collecting stubble box 9, and described bar chain conveying mechanism 5 comprises bar chain 10, front Support sprocket 11, middle support sprocket 12 and drive sprocket 13, the bar chain 10 between front support sprocket 11 and middle support sprocket 12 is the ascending section, and the bar chain 10 of ascending section and horizontal plane angle are 30 °, the bar chain 10 between the middle support sprocket 12 and the drive sprocket 13 is a horizontal section, and the bar chain 10 of the horizontal section is parallel to the horizon...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the hammer head 16 in this embodiment is a rubber hammer head, and when separating potatoes or Chinese medicinal materials, a rubber material hammer head is used, and the number of teeth hitting the sprocket 23 is 30. Direction device 24 adopts motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com