Shaft part induction quenching and synchronous induction tempering method and heating inductor

A technology for heating inductors and shaft parts, which is applied in the direction of quenching devices, furnace types, heat treatment furnaces, etc., can solve the problems of long product circulation period and bump damage on the surface of parts, so as to improve the utilization rate of electric energy, prevent bump damage, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

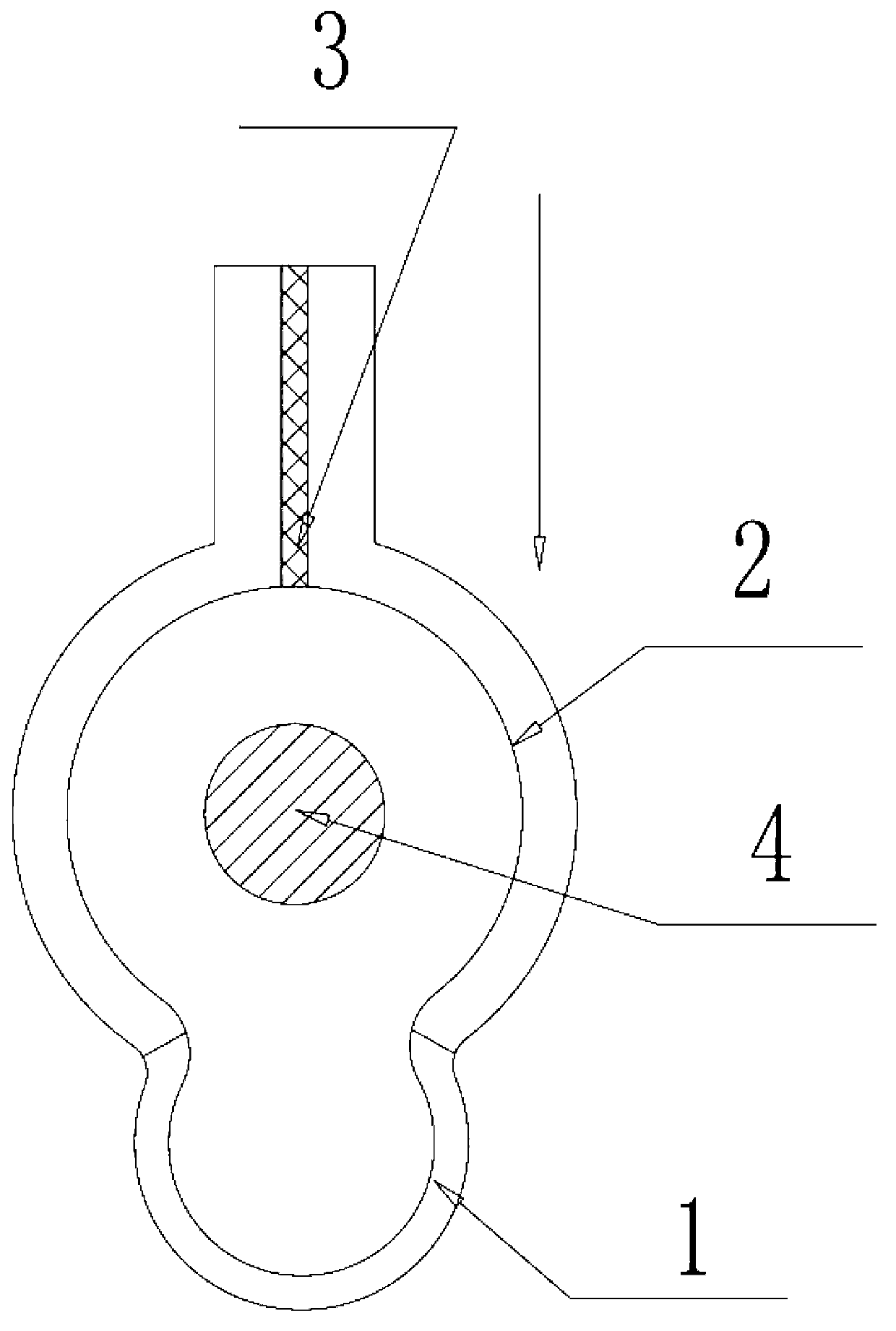

[0017] Embodiment: The workpiece used in this embodiment: the outer diameter of the spline of the workpiece is 35mm, the diameter of the neutral part is φ30mm, the material is SAE1045, and the hardness of the quenched and tempered matrix of the forging is HB217~245.

[0018] An induction hardening process, especially a process of induction tempering immediately after quenching, in which the shaft part 4 is placed on the equipment supported by double tops, the inductor is adjusted to be concentric with the center of the workpiece, and the inductor is moved to the shaft part 4 The initial processing part at the lower end, the rotation speed of the shaft part 4 is 90~150rpm, the uniform heating frequency is 9000~10500HZ during induction hardening, stay for a period of time to heat the surface of the part to 890℃~910℃, and move the induction hardening upward Spray JX aqueous solution at 23~40°C with a flow rate of 30-80L / Min for cooling and quenching, scanning heating to the end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com