Chromalizing device and process for small hole of driving device for control rod of nuclear reactor

A driving device and nuclear reactor technology, applied in the direction of electrodes, cells, electrolysis process, etc., can solve the problems of excessive growth of coating, difficulty in controlling the uniformity of coating thickness, and easy initiation of cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

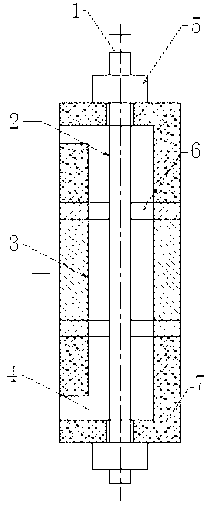

[0027] Such as figure 1 As shown, the present invention is a chrome-plating device for small holes of a nuclear reactor control rod driving device, including an anode 2 and an auxiliary cathode 6 . In order to realize the purpose of uniform axial growth of the coating in the present invention, the auxiliary cathode 6 is in the shape of a sheet and is arranged to cover both ends of the small hole, and the auxiliary cathode 6 is connected with a power line at the suction end. The anode 2 is a Pt anode whose outer diameter is 1 / 4 to 1 / 3 of the inner diameter of the small hole; There is a radial gap between them.

[0028] The two ends of the anode 2 exposed on the outside of the small hole are covered with an anode insulating sleeve 7. The anode insulating sleeve 7 is in the shape of a sleeve with an opening at one end and an end cap at the other end. The opening end of the anode insulating sleeve 7 covers the outer end surface of the auxiliary cathode 6. set up. The end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com