Discharge pipe for pushing method installation

A technology for installation and sewage pipes, applied in water supply devices, sewer pipe systems, waterway systems, etc., can solve the problems of poor reliability of sewage pipes, easy leakage, insufficient rigidity, etc., and achieve high cost performance, reliable sealing, and easy to use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

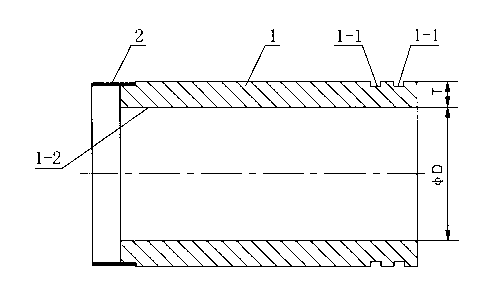

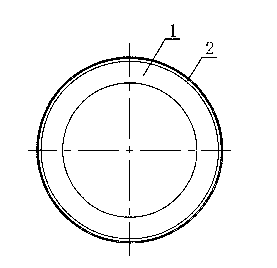

[0015] Such as figure 1 and figure 2 As shown, a sewage pipe for installation by pipe jacking method includes a pipe jacking body 1 . The outer diameter of one end of the pipe jacking body 1 is provided with a steel sleeve 2, and the outer diameter of the other end of the pipe jacking body 1 is provided with an annular groove 1-1.

[0016] There are two annular grooves 1-1.

[0017] The wall thickness of the pipe jacking body 1 is equal to 10% of the inner diameter 1-2 of the pipe jacking body. In the figure: T represents the wall thickness, φD represents the inner diameter of the pipe jacking body 1-2. For example, the inner diameter φD is 1200mm, and the wall thickness T is 120mm.

[0018] The cross section of the pipe jacking body 1 is circular. That is, the pipe jacking body 1 is a round pipe.

[0019] The invention is a concrete cement pipe. The wall thickness of the pipe jacking body 1 of the present invention is the best when equal to 10% of the inner diameter 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com