Device and method for measuring downhole liquid production profile flow and water holding capacity

A liquid production profile and water holdup technology, applied in the direction of earthwork drilling and production, wellbore/well components, etc., can solve problems such as failure, inability to accurately measure the size of water holdup, and decreased sensitivity, so as to reduce the impact, The effect of improving measurement sensitivity and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

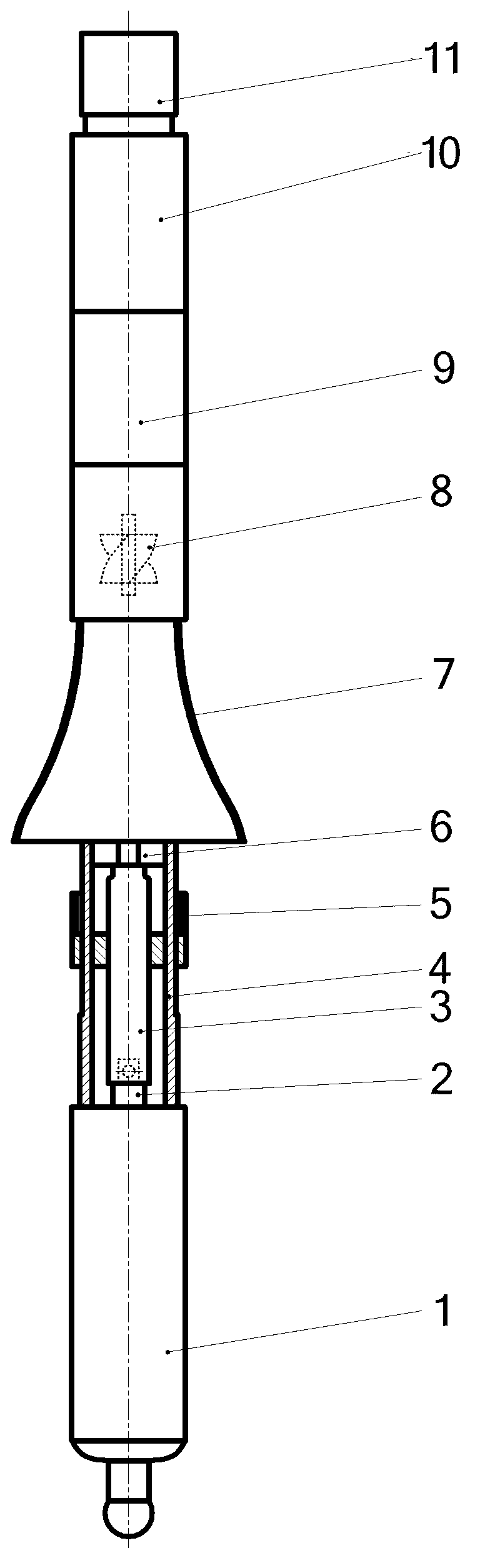

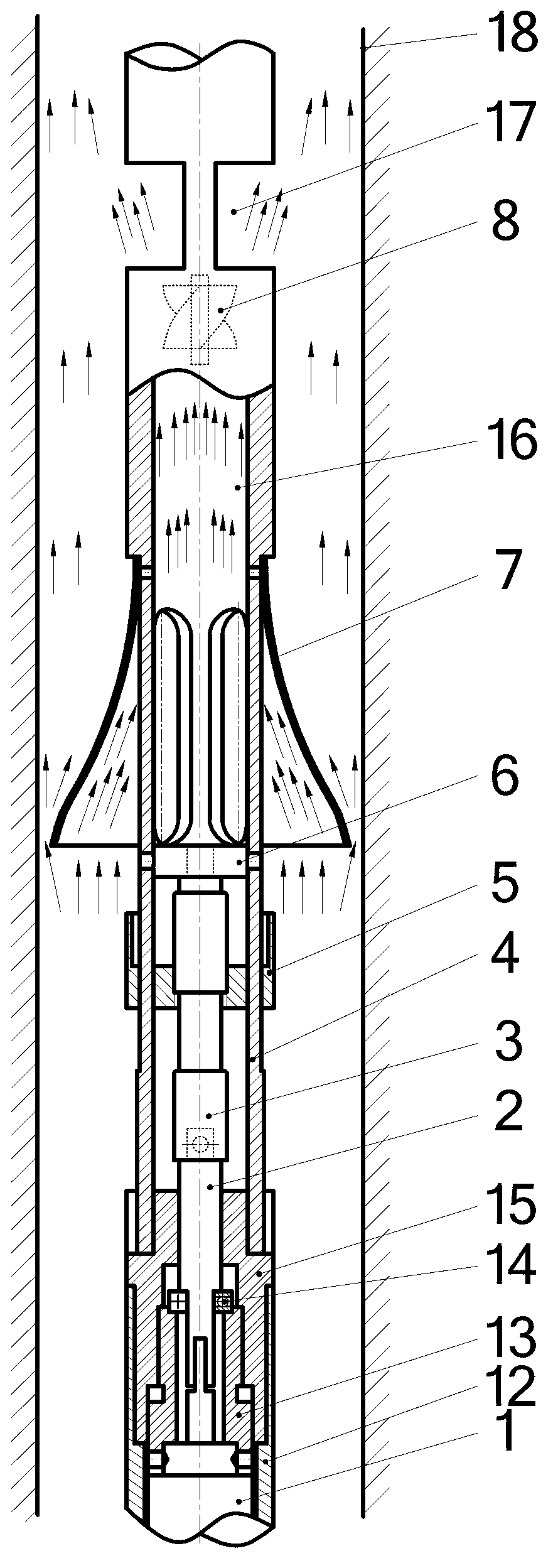

[0032] refer to figure 1 , a device for measuring the flow rate and water holdup of the downhole liquid production section, including a motor and a reducer unit 1, the motor and reducer unit 1 are connected through a transmission shaft 2 and a coupling 3, and the coupling 3 is connected to the umbrella cup 5 connection, the upper end of the transmission shaft 2 is fixed with the wire-passing plate 6, the wire-passing plate 6 is fixed on the collector frame 4, and the collector frame 4 is fixed with the current-collecting umbrella 7, and the upper part of the current-collecting umbrella 7 is sequentially from bottom to top A turbine flowmeter 8, a capacitance sensor 9, a temperature and pressure sensor 10 and a tap 11 are provided.

[0033] refer to figure 2, the header 4 is connected with the upper pressure pipe 15, the upper pressure pipe 15 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com