Inclination fragmentation ore body segment top board reconstruction middle-deep hole ore break down filling mining method

A backfill mining method and ore body technology, applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of large loss of ore resources, complex mining process, high mining and filling costs, and achieve high rock drilling efficiency and economical efficiency. The effect of good benefit and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

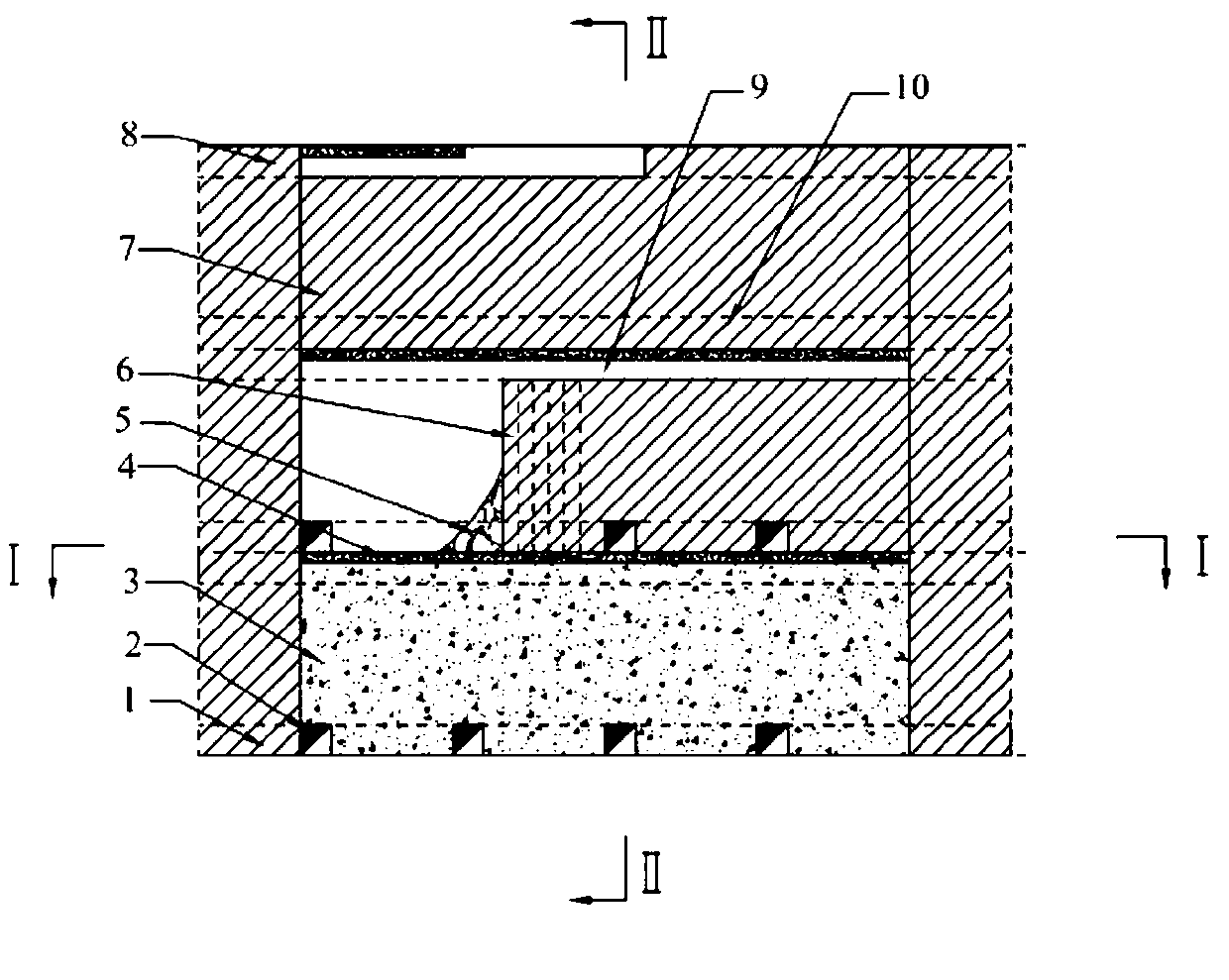

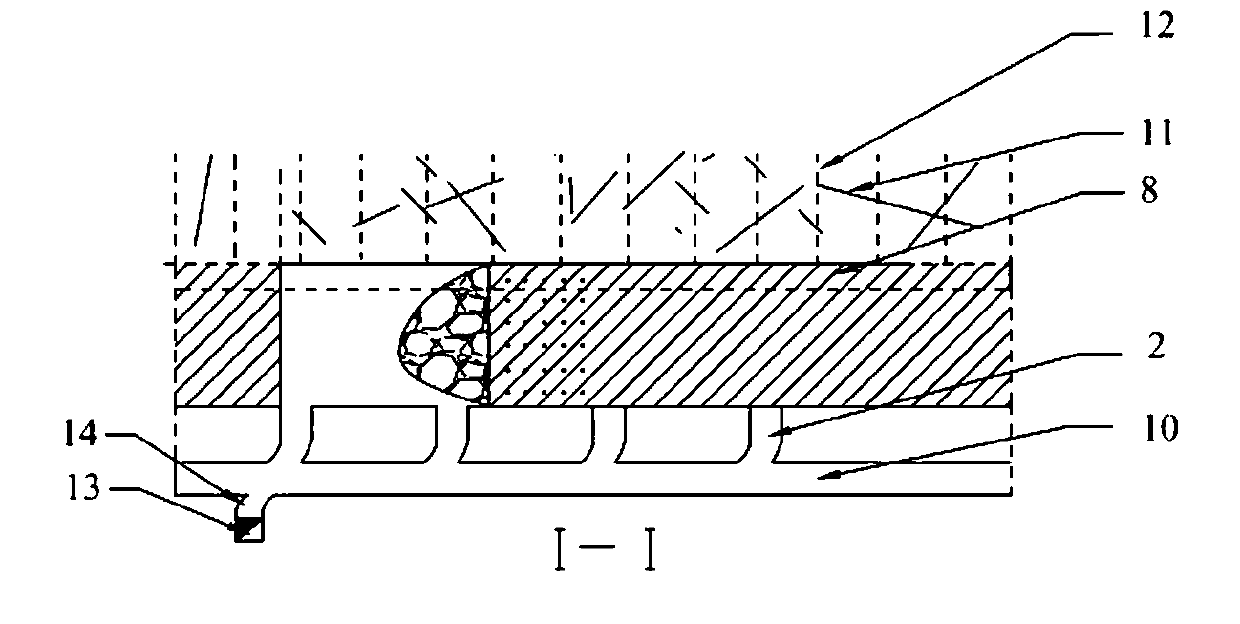

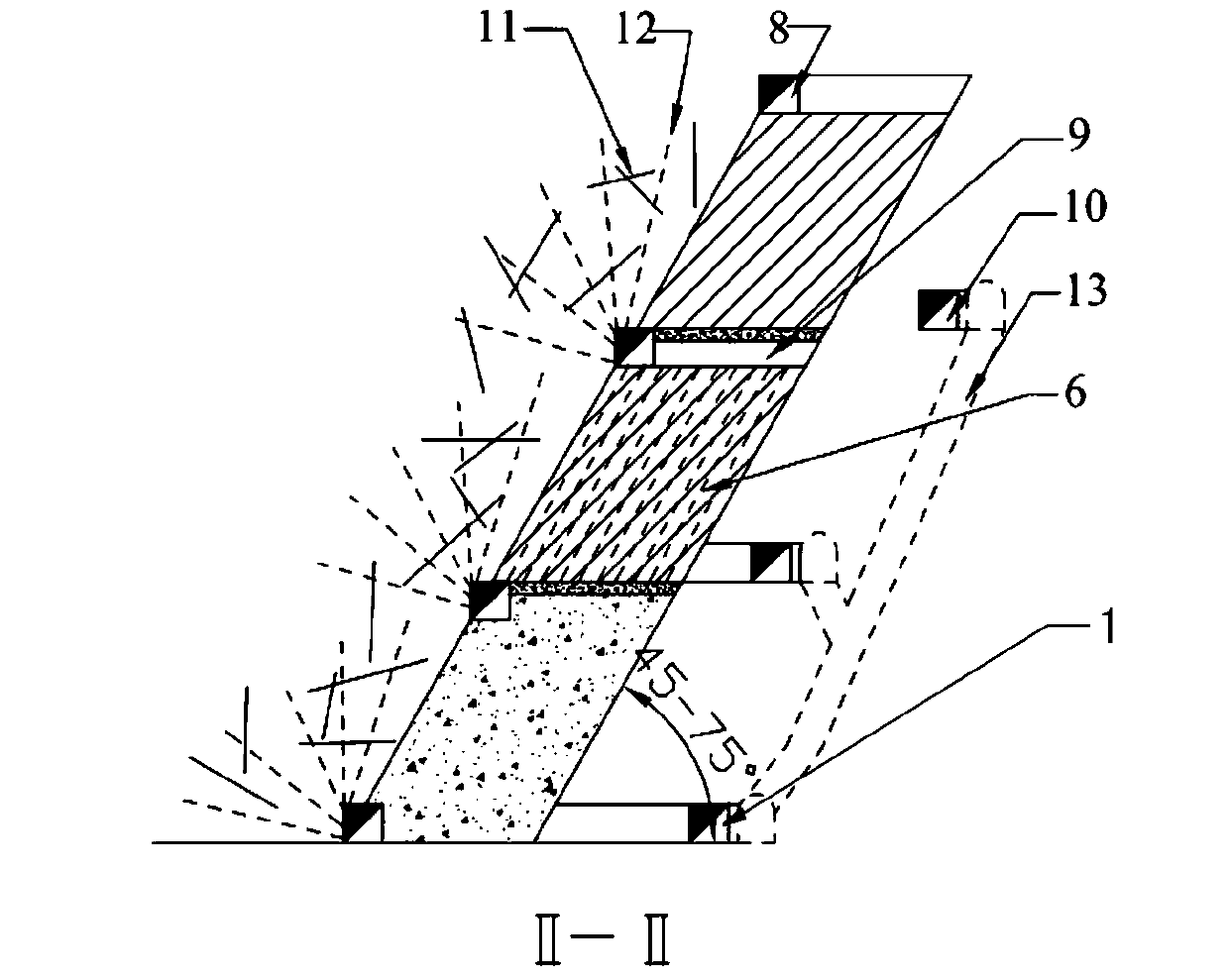

[0016] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. This example is only used as an example to explain the technical solution of the present invention, and does not limit the scope of protection.

[0017] (1) As shown in the figure, the ore body is divided into middle sections with a height between 50 and 70m, and the middle transportation roadway 1 is arranged at the lower part of each middle section; then each middle section is divided into middle sections with a height between 15 and 25m. The sub-sections, and arrange the sub-transportation lane 10 in each sub-section, and the sub-transportation level lane 10 is connected with the middle transportation roadway 1 through the chute 13. The middle section is divided into several continuous mining units of 50-100m (the length is determined by the strength of the artificial roof) along the ore body trend.

[0018] (2) Segmented transportation level ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com