Thrust ball bearing for vertical lathe workbench

A thrust ball bearing, worktable technology, applied in the direction of ball bearings, bearing components, shafts and bearings, etc., can solve the problems of complex structure, affecting the service life of the bearing, and the running accuracy can only meet the general requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

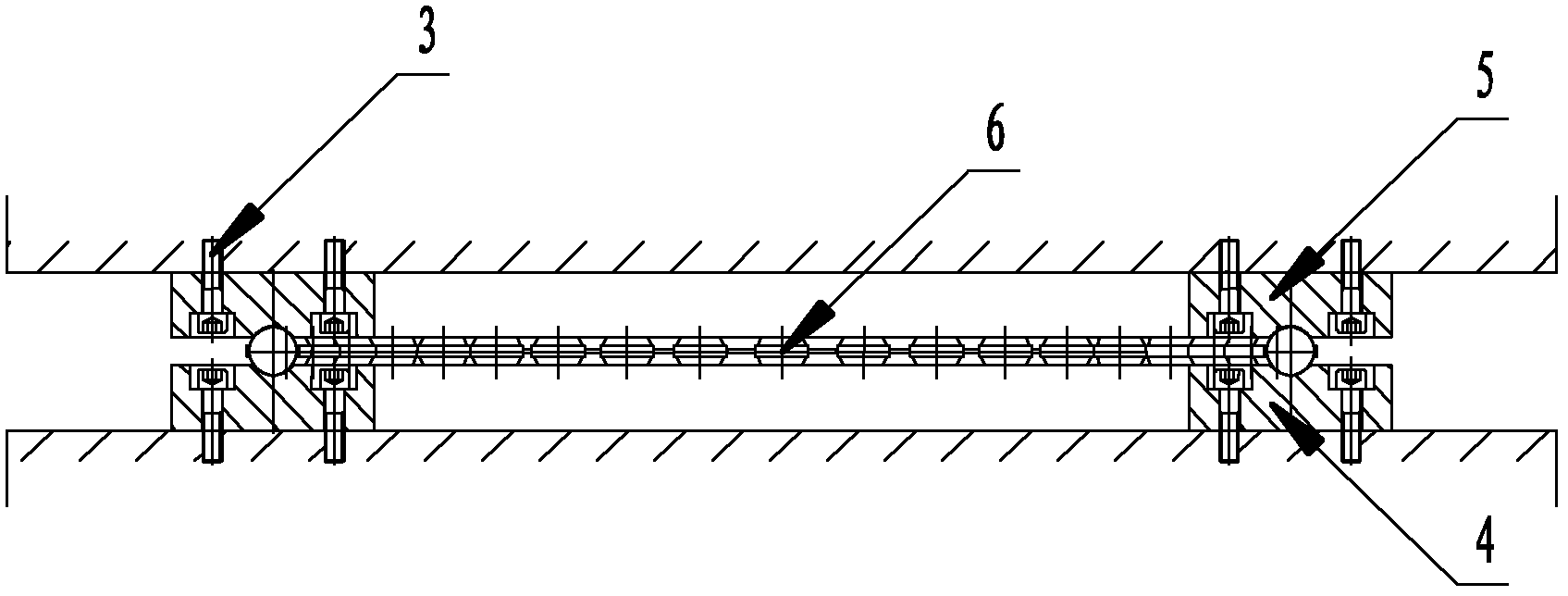

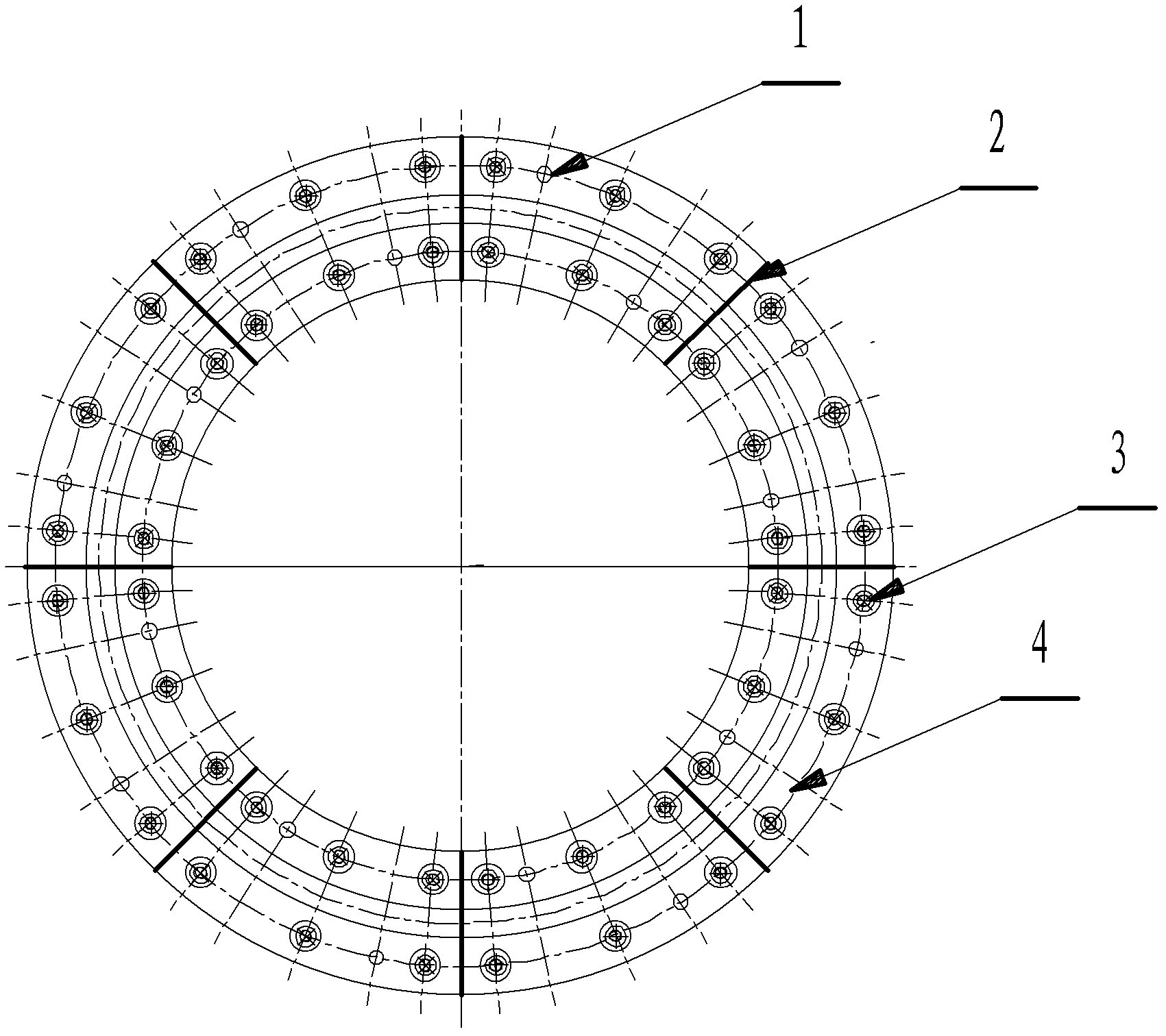

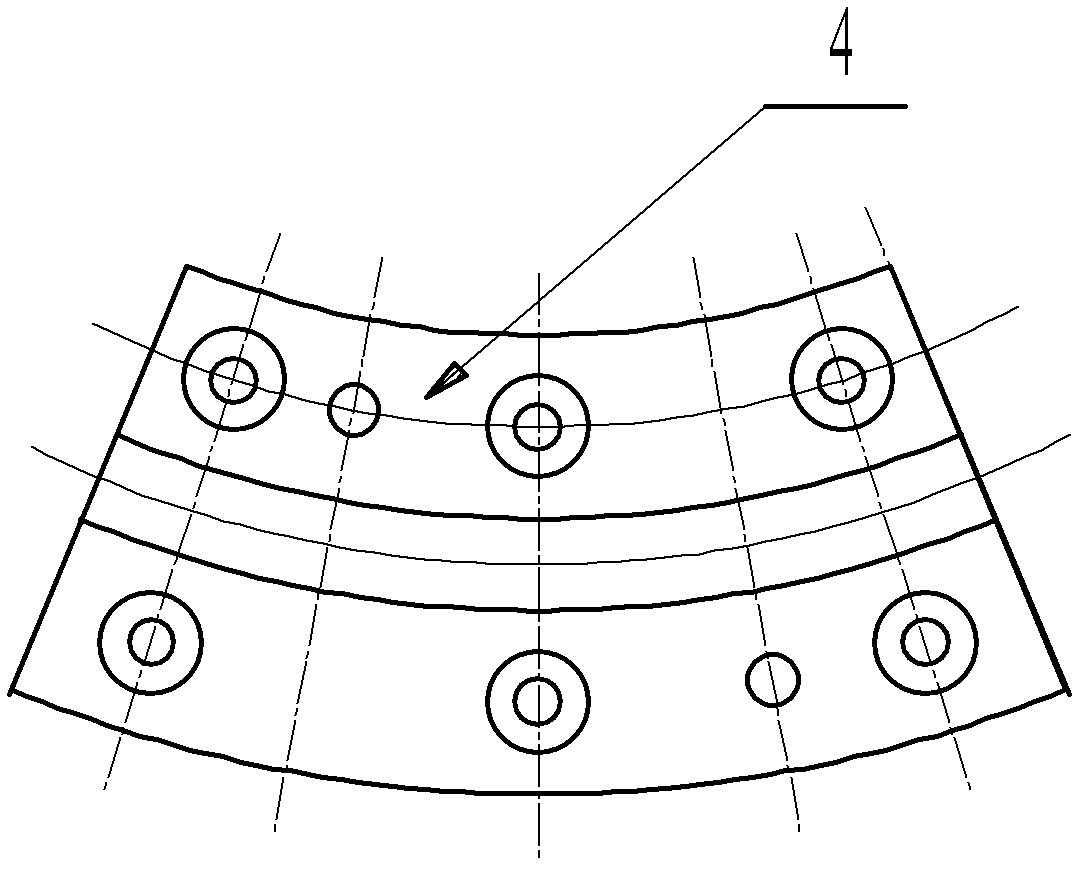

[0010] The non-integral circular track thrust ball bearing provided by the present invention includes equally divided sector blocks 4, 5 or horizontal and vertical cutting blocks ( Figure 4 ), positioning pin 1, screw 3, steel ball cage 6, high-strength wear-resistant adhesive 2 and other parts. Each equalized fan-shaped block or horizontal and vertical cutting block of the present invention is forged with bearing material GCr15, and assembled on the assembled track base surface of the vertical lathe base and the track base surface of the vertical lathe workbench after processing, and the assembly process belongs to the known technology , so no explanation is given. Form a circle composed of multiple equally divided fan-shaped blocks or horizontal and vertical cutting blocks, and then carry out CNC cutting and machining of the track. After the processing is completed, disassemble each block for heat treatment, and then assemble it to the base surface , Fill the gap with high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com