Micro alternating current magnet yoke flaw detector

A flaw detector and magnetic yoke technology, which is applied in the direction of material magnetic variables to achieve the effects of easy portability, wide application and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

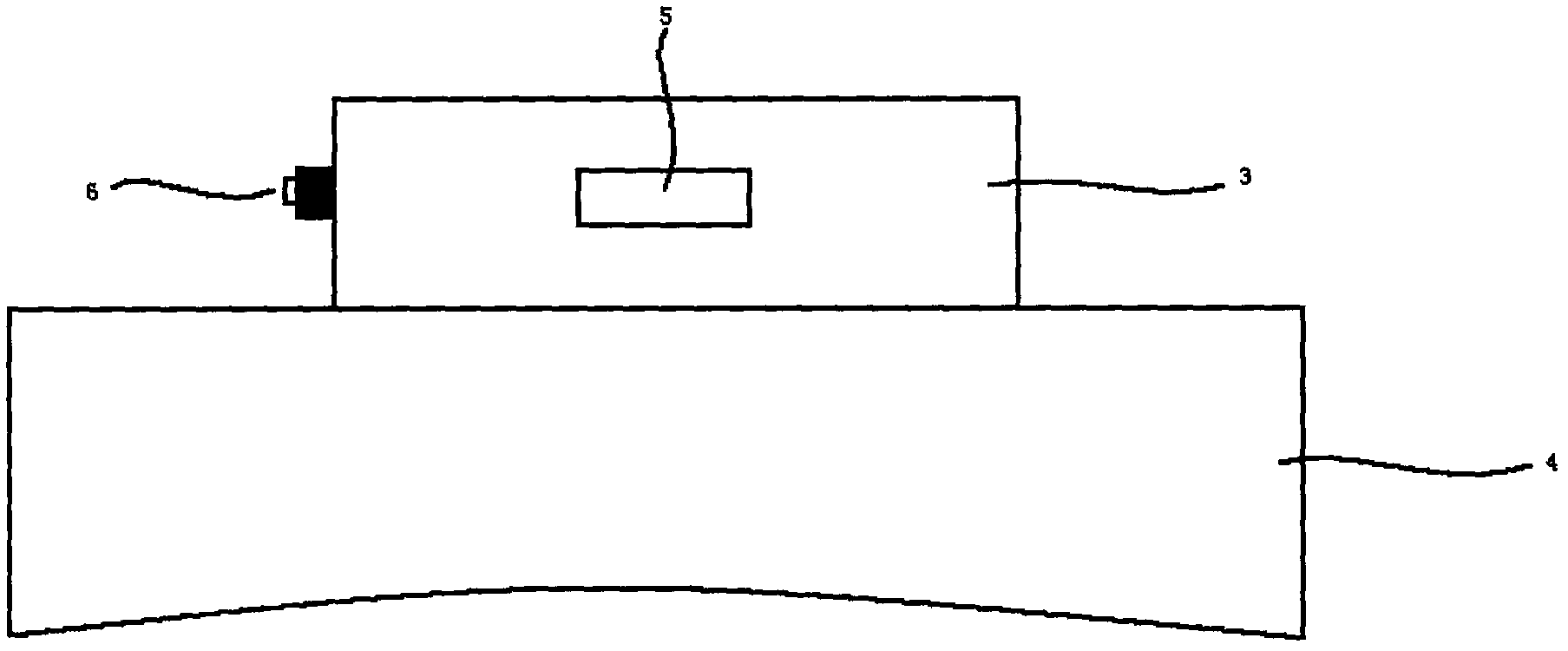

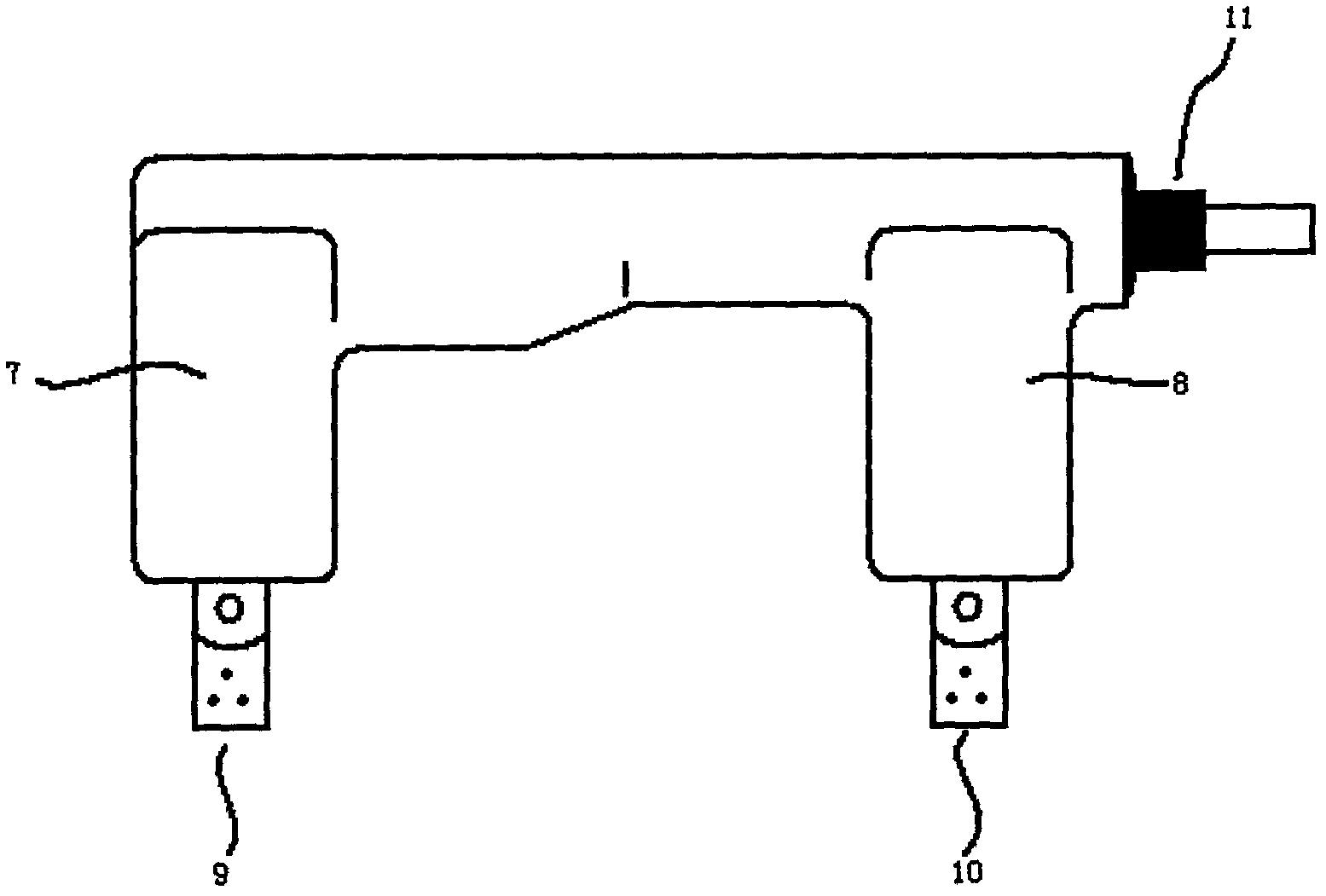

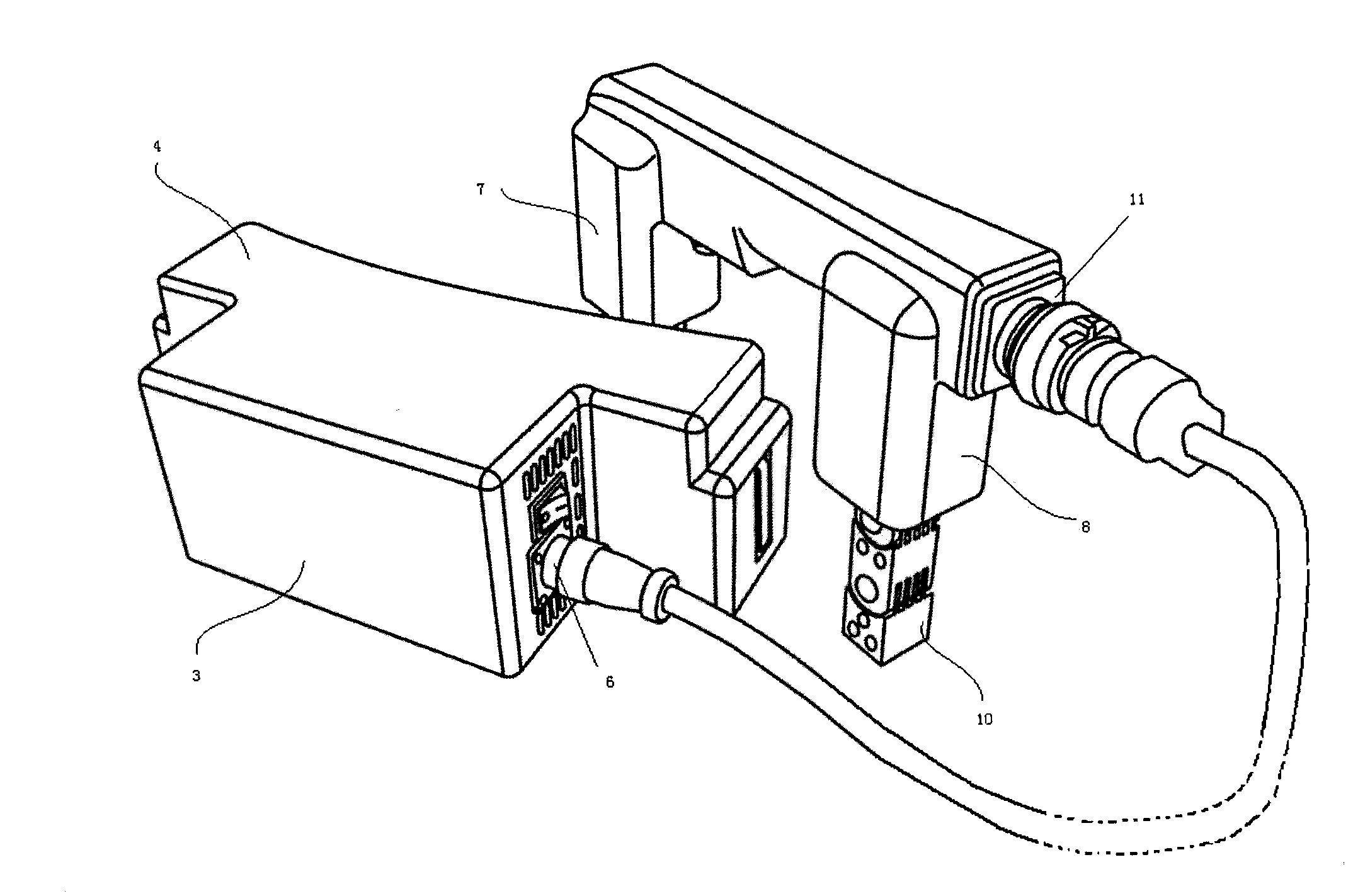

[0017] The miniature AC yoke flaw detector of this embodiment uses a battery as the energy source, which is transmitted to the flaw detection probe after being processed by inverter, frequency conversion, and shifting. In particular, a lithium battery is used as the energy source, which is transmitted to the flaw detection probe after being processed by inverter, frequency conversion, and shifting. One charge can ensure continuous work for more than 10 hours, which makes up for the shortcomings of existing portable flaw detectors in the domestic market, and is easy to operate, convenient to carry, and widely used. Preferably, the program-controlled inverter according to this embodiment automatically adjusts the power level according to the battery voltage value, through automatic adjustment, liquid crystal digital display of working conditions and battery undervoltage alarm. The device can automatically adjust the power level according to the battery voltage value during the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com