Electrode lead connection body, nonaqueous electrolyte electricity storing device and method of manufacturing the same

A technology of electrode leads and connectors, which is applied in the field of electrode lead connectors and non-aqueous electrolyte storage devices, can solve problems such as difficulty in obtaining sealing, electrolyte leakage, and increased loss, and achieve assembly process and sufficient joint strength , the effect of reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

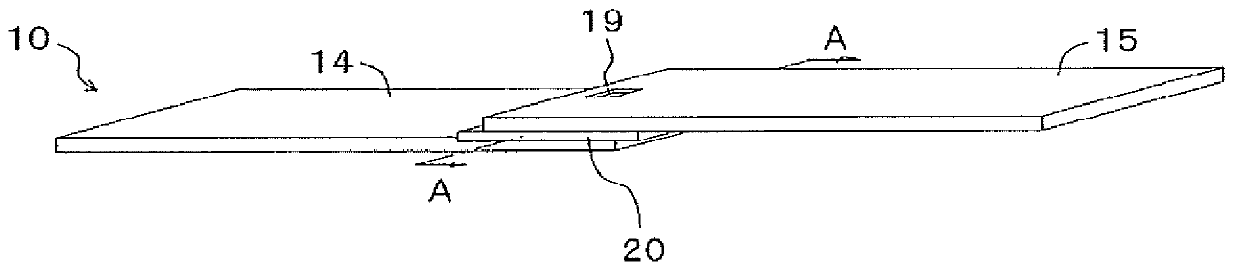

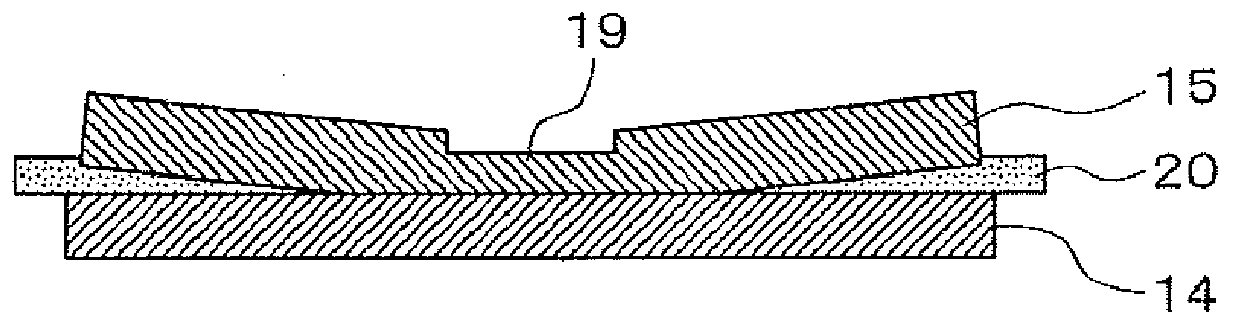

[0060] An Al plate having a thickness of 0.3 mm, a width of 30 mm, and a length of 50 mm was used as the first member of the electrode lead connection body, and a Cu plate having the same size as the first member was used as the second member.

[0061] A polypropylene-based thermoplastic resin film is sandwiched between the first member and the second member, and the second member is superimposed on the upper surface with an overlapping amount of 10 mm, and ultrasonic waves are applied from the Cu plate side of the second member to apply a load. join.

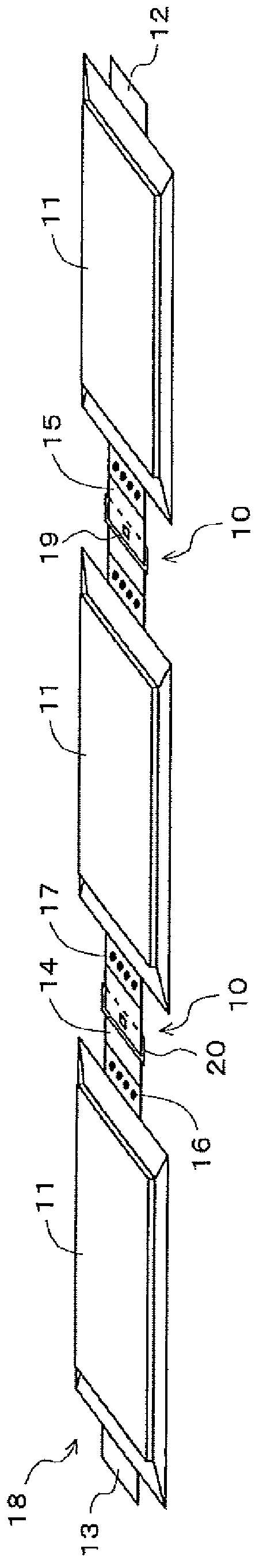

[0062] The connection of the battery cell of a lithium ion secondary battery is performed using this electrode lead connection body. The positive electrode of the battery cell uses Al and the negative electrode uses Cu, and together with the separator and the electrolyte, it is sealed into a rectangular shape by an exterior body composed of an aluminum laminated film, and the positive electrode lead made of Al and the lead wire...

Embodiment 2)

[0065] An Al plate having a thickness of 0.3 mm, a width of 30 mm, and a length of 50 mm was used as the first member of the electrode lead connection body, and a Cu plate having the same size as the first member was used as the second member.

[0066] A polypropylene-based thermoplastic resin is sandwiched between the first member and the second member, and the second member is placed on top with an overlapping amount of 10mm, and ultrasonic waves are applied from the Cu plate side of the second member to apply a load to join. In addition, holes for electrode welding are formed in the first member and the second member by press working, and protrusions are formed on edges of the holes for electrode welding.

[0067] The connection of the battery cell of a lithium ion secondary battery is performed using this electrode lead connection body. Al is used for the positive electrode of the battery cell, and Cu is used for the negative electrode. They are sealed together with a sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com