Composite core material for vacuum insulation panel, preparation method thereof, and vacuum insulation panel using same

A technology of vacuum insulation material and core material, which is used in heat exchange equipment, household refrigeration devices, lighting and heating equipment, etc., can solve the problems of insulation material limitation, reduced durability, and reduced durability performance, and achieve excellent thermal insulation performance and long-term performance. Excellent durability, initial thermal insulation performance and long-term durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation of glass fiber board can be prepared by wet preparation method, which is to disperse glass fiber into inorganic binder (one or more of soluble sodium silicate, alumina sol, silica sol, alumina phosphate) The method of making the board. In particular, soluble sodium silicate comprises water, silica powder and sodium hydroxide.

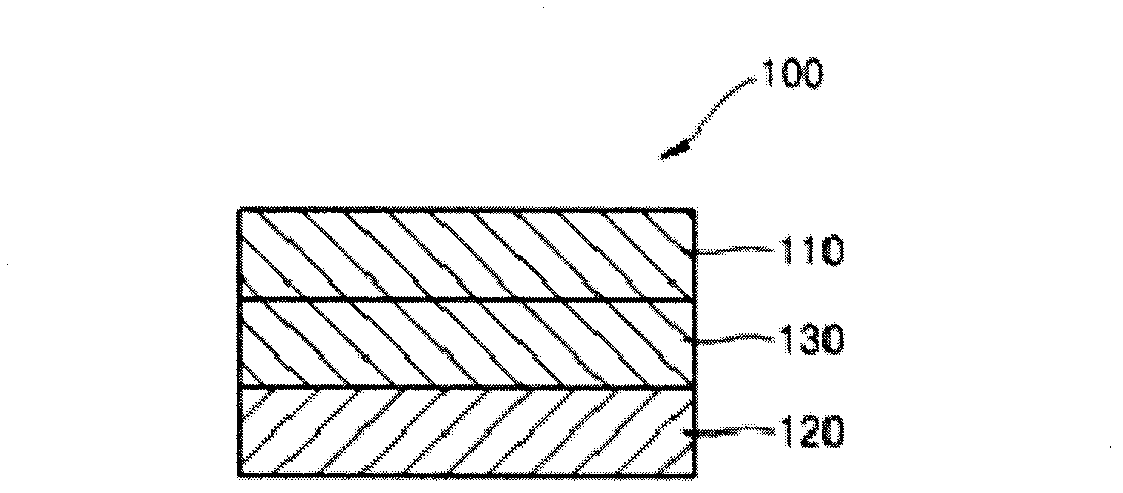

[0044] The following glass fiber board 110 can be proposed, which is composed of 55% to 70% of silicon oxide, 0.5% to 5.0% of aluminum oxide, 2.5% to 4.0% of magnesium oxide, 4.5% to 12% of calcium oxide and 0.1% to 0.5% Formation of potassium oxide, etc. Additionally, fiberglass panels are available in a variety of configurations.

[0045] The fiberglass board 110 includes a material that ensures excellent long-term durability, and may be in the form of a fiberglass board, sheet, or paper product. In addition, as a material for improving long-term durability, one or more of fumed silica powder, silica powder, perlite powder, and...

Embodiment 1

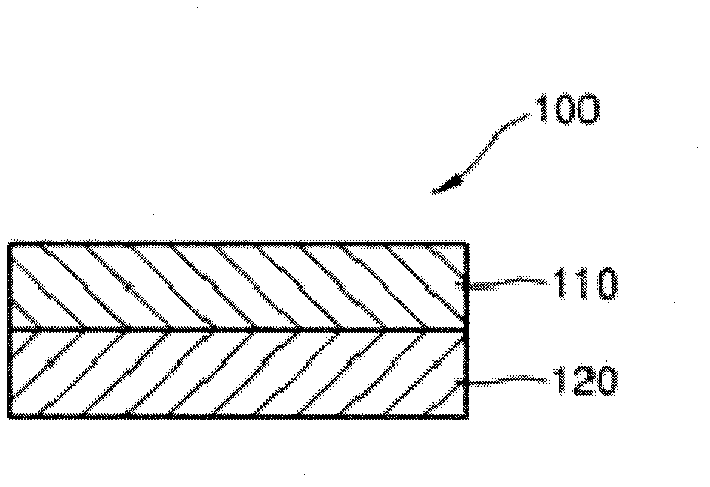

[0072] First, the above figure 1 The core material formed by laminating a single layer of glass fiber wool and glass fiber board by the lamination method is prepared into a size of 8 mm × 190 mm × 250 mm (thickness × width × length) and then used for vacuum insulation Material core material.

[0073] Next, form the outer skin material, which is composed of 12 μm polyvinylidene chloride (PVDC) / polyethylene terephthalate (PET) film, 25 μm nylon (Nylon) film, 7 μm aluminum foil and 50 μm linear Structure formation of low density polyethylene (LLDPE) films.

[0074] Second, if Figure 9 As shown, 2 getter materials made by bagging 25 g of quicklime (CaO) with a purity of 95% were inserted into the surface of the core material.

[0075] Then, after inserting the core material into the bag body, it was sealed in a vacuum state of 10 Pa, and the vacuum heat insulating material of the present invention was produced.

Embodiment 2

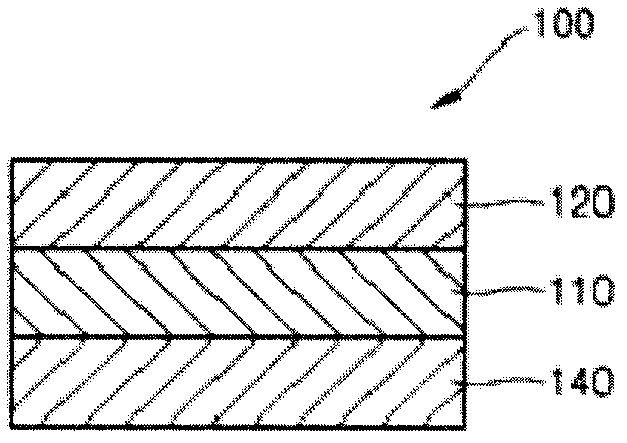

[0077] The vacuum insulation material was prepared under the same conditions as in the above-mentioned Example 1, but the core material was formed by laminating a layer of glass fiber board on top of two layers of glass fiber wool by lamination, and the core material was made of Into the size of 8mm×190mm×250mm (thickness×width×length).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com