Phase change waste heat recovery ventilator for solar greenhouse

A waste heat recovery and solar greenhouse technology, applied in greenhouse cultivation, agricultural machinery and equipment, climate change adaptation, etc., can solve problems such as ineffective storage of heat energy, poor heat storage conditions in greenhouses, insufficient thermal insulation performance of solar greenhouses, etc., and achieve improved Effects on building performance and production capacity, improved thermal storage and insulation levels, efficient storage and release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

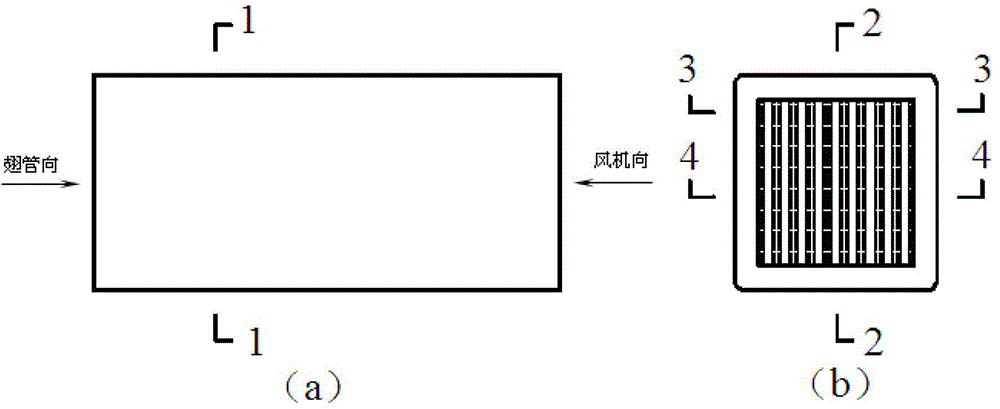

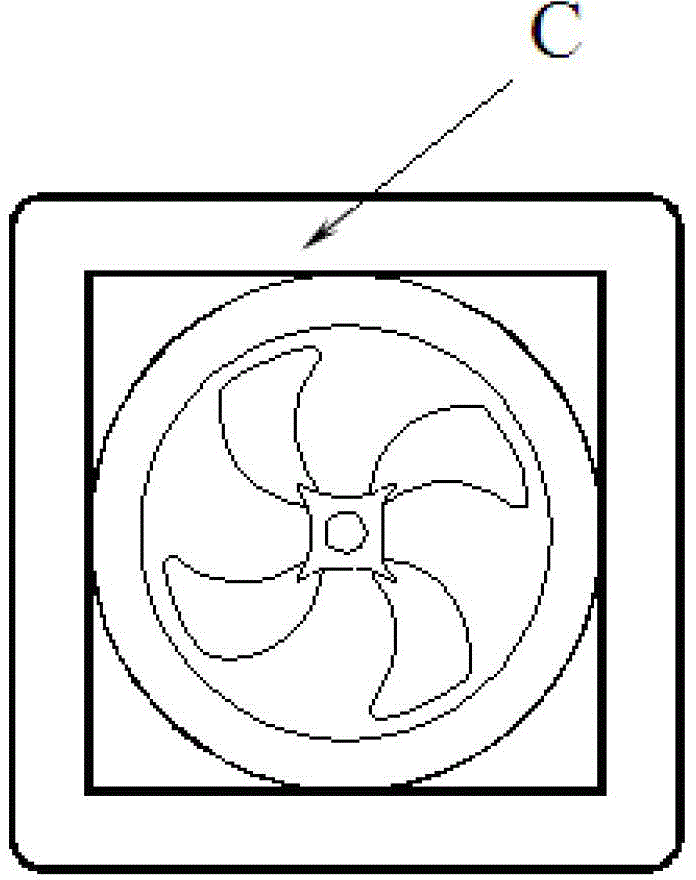

[0024] Refer to attached Figure 1-6 , this embodiment provides a phase-change waste heat recovery heat exchange fan for a solar greenhouse. Its structure includes a composite phase-change heat box A, and a heat-exchange finned tube B and an axial flow fan are arranged in the composite phase-change heat box A. C (the airflow direction can be adjusted by changing the direction of rotation), wherein, the axial flow fan C is located on one side of the composite phase change heat box A, and the heat exchange finned tube B is located on the other side of the composite phase change heat box A; A composite phase change material D is stored on the inner wall of the conversion heat box A.

[0025] The material of the composite phase change heat box A is engineering plastics, and the box body of the composite phase change heat box A has a connected cavity structure (for example, a zigzag arrangement structure, except for the corresponding position where the axial flow fan is installed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com