Multi-bed coupling cooperation and interaction type device for separating multicomponent mixture by thermal current

A multi-component and mixture technology, applied to the removal of solid waste, etc., can solve the problems of low efficiency of manual sorting, increase of material humidity, heavy workload, etc., to achieve the goal of weakening interaction, avoiding material entanglement, and prolonging residence time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following, the present invention will be further clarified with reference to the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. After reading the present invention, those skilled in the art will understand various aspects of the present invention. Modifications in equivalent forms fall within the scope defined by the appended claims of this application.

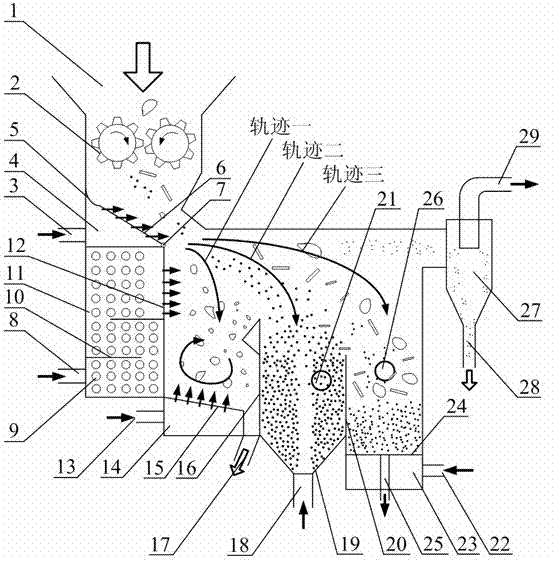

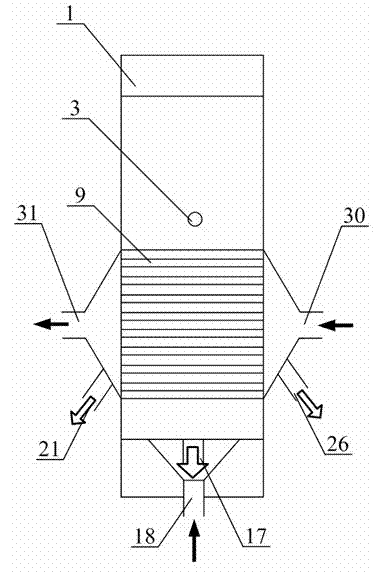

[0028] figure 1 The labels in the middle are: raw material inlet 1, double spiral wheel 2, auxiliary air inlet 3, auxiliary air chamber 4, flexible connection 5, draft plate 6, living hinge 7, dry air inlet 8, heat pipe 9, partition 10 , Drying air chamber 11, Drying air distribution plate 12, One bed fluidized air inlet 13, One bed air chamber 14, Inclined air distribution plate 15, One / two bed partitions 16, One bed discharge port 17, Two beds Spouting air inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com