Cationic polyelectrolyte-polypyrrole composite polymer resistive-type humidity-sensitive element and manufacturing method thereof

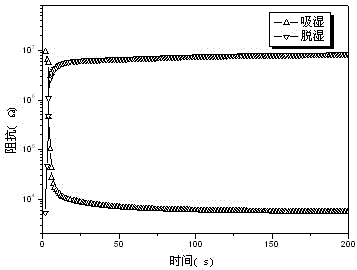

A composite polymer and cationic polymerization technology is applied in the field of cationic polyelectrolyte and polypyrrole composite polymer resistance type humidity sensor, which can solve the problems of narrowing the detection range of the humidity sensor, reducing the electrical conductivity of the composite material, and adversely affecting the application, etc. Achieve the effect of reducing wet hysteresis, speeding up response time, and weakening interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

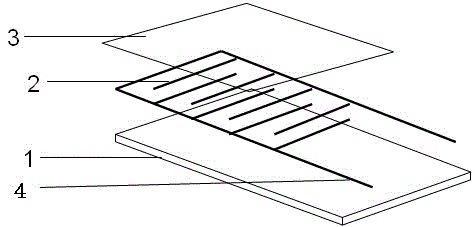

[0026] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0027] The interdigitated gold electrodes on the surface of the ceramic substrate have an interdigital width of 100 μm and an interdigital gap of 100 μm.

[0028] 2) Add 3.5 g of 1-vinyl-3-ethylimidazole bromide and 0.035 g of azobisisobutyronitrile into 20 ml of chloroform, stir at room temperature for one hour, heat up to 90°C for 3 hours, and cool the product to At room temperature, discard the solvent, dissolve with an appropriate amount of methanol, then precipitate in a large amount of acetone, filter with suction, and dry in a vacuum oven until constant weight to obtain a white solid, which is polybrominated 1-vinyl-3-ethylimidazole ;

[0029] 3) Add 0.35 g of the polybrominated 1-vinyl-3-ethylimidazole and 0.5 g of pyrrole monomers prepared in step 2) into 30 mL of deionized water in turn, stir well, Add 40 milliliters of 0...

Embodiment 2

[0036]1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0037] The interdigitated gold electrodes on the surface of the ceramic substrate have an interdigital width of 20 μm and an interdigital gap of 20 μm.

[0038] 2) Add 1.0 g of 1-vinyl-3-ethylimidazole bromide and 0.03 g of azobisisobutyronitrile into 50 ml of chloroform, stir at room temperature for one hour, raise the temperature to 100°C for 5 hours, and cool the product to At room temperature, discard the solvent, dissolve with an appropriate amount of methanol, then precipitate in a large amount of acetone, filter with suction, and dry in a vacuum oven until constant weight to obtain a white solid, which is polybrominated 1-vinyl-3-ethylimidazole ;

[0039] 3) Add 0.1 g of polybrominated 1-vinyl-3-ethylimidazole and 0.5 g of pyrrole monomers prepared in step 2) into 50 mL of deionized water in turn, stir evenly, and under ultras...

Embodiment 3

[0043] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0044] The interdigitated gold electrodes on the surface of the ceramic substrate have an interdigital width of 40 μm and an interdigital gap of 40 μm.

[0045] 2) Add 2.0 g of 1-vinyl-3-ethylimidazole bromide and 0.03 g of azobisisobutyronitrile into 20 ml of chloroform, stir at room temperature for one hour, raise the temperature to 60°C for 2 hours, and cool the product to At room temperature, discard the solvent, dissolve with an appropriate amount of methanol, then precipitate in a large amount of acetone, filter with suction, and dry in a vacuum oven until constant weight to obtain a white solid, which is polybrominated 1-vinyl-3-ethylimidazole ;

[0046] 3) Add 0.3 g of the polybrominated 1-vinyl-3-ethylimidazole and 0.5 g of pyrrole monomers prepared in step 2) into 20 mL of deionized water in turn, stir well, and within 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interdigital width | aaaaa | aaaaa |

| Interdigital gap | aaaaa | aaaaa |

| Interdigital width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com