Control method of short circuiting transient process in consumable electrode gas shielded welding

A technology of melting electrode gas and control method, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of process stability damage, large reactance, high current and extremely fast switching difficulties, etc., to prevent molten droplet explosion and splashing , Control effect Precise and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these implementations do not limit the present invention, and any structural, method, algorithmic or functional transformations made by those skilled in the art based on these implementations are included in the protection scope of the present invention.

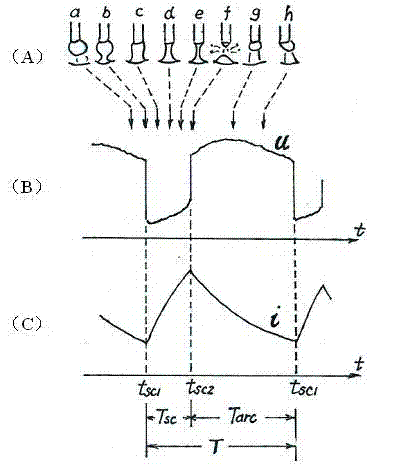

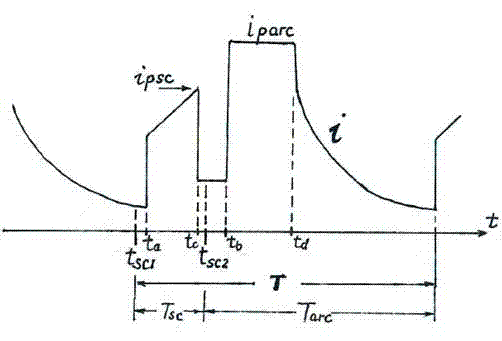

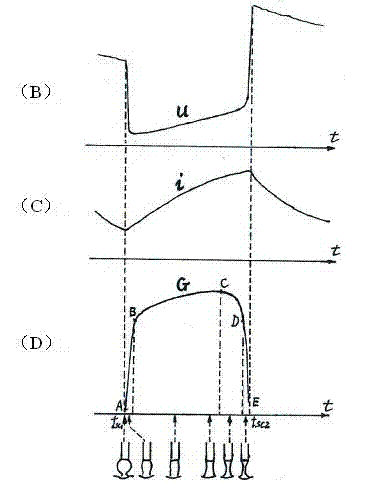

[0025] see Figure 4 to Figure 6 Shown is the corresponding control waveform diagram of the control method of the short-circuit transition process in MIG / MAG welding according to the present invention. refer to figure 1 , figure 2 and Figure 6 As shown, the welding process of metal gas shielded welding can be understood as the arcing stage T arc and short-circuit phase T sc duplicate status.

[0026] Among them, the arcing stage T arc It also includes the early stage of arcing (corresponding to figure 2 , 6 t in sc2 to t b between periods), mid-arc period (corresponding to fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com