Laser-electric arc composite welding head adjusting device

A laser welding head and composite welding technology, applied in laser welding equipment, auxiliary devices, welding equipment and other directions, can solve the problems of large volume of the three-dimensional adjustment mechanism, inability to adjust the angle, and inability to adjust the three-dimensional coordinates of the laser beam of the welding torch, etc. Welding quality, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

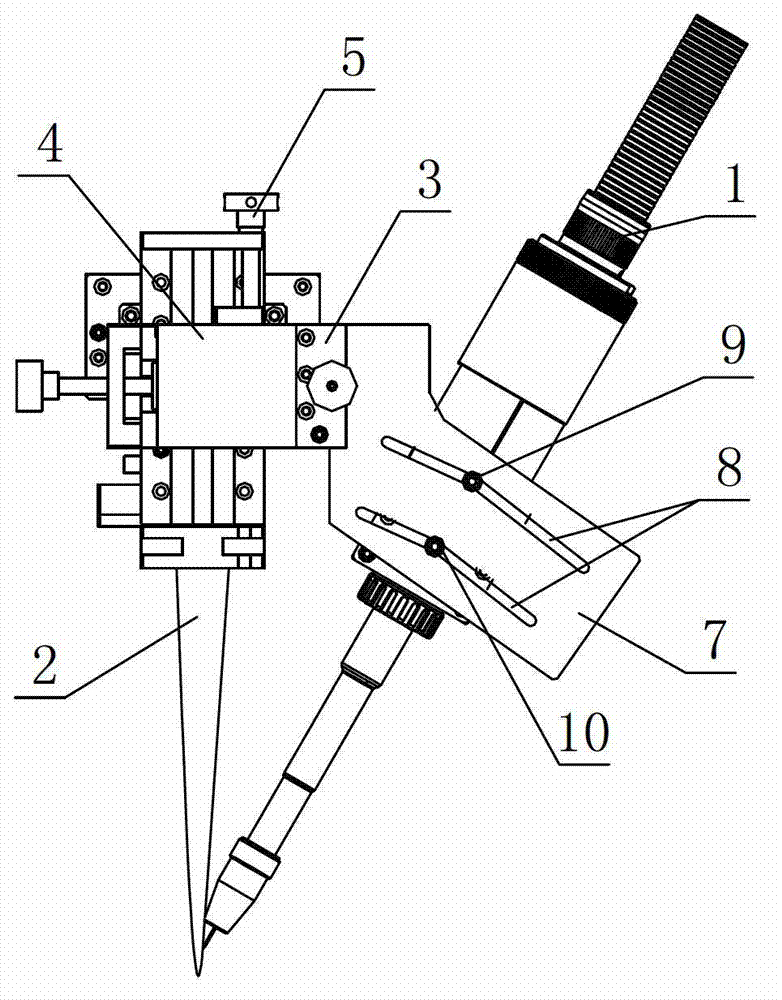

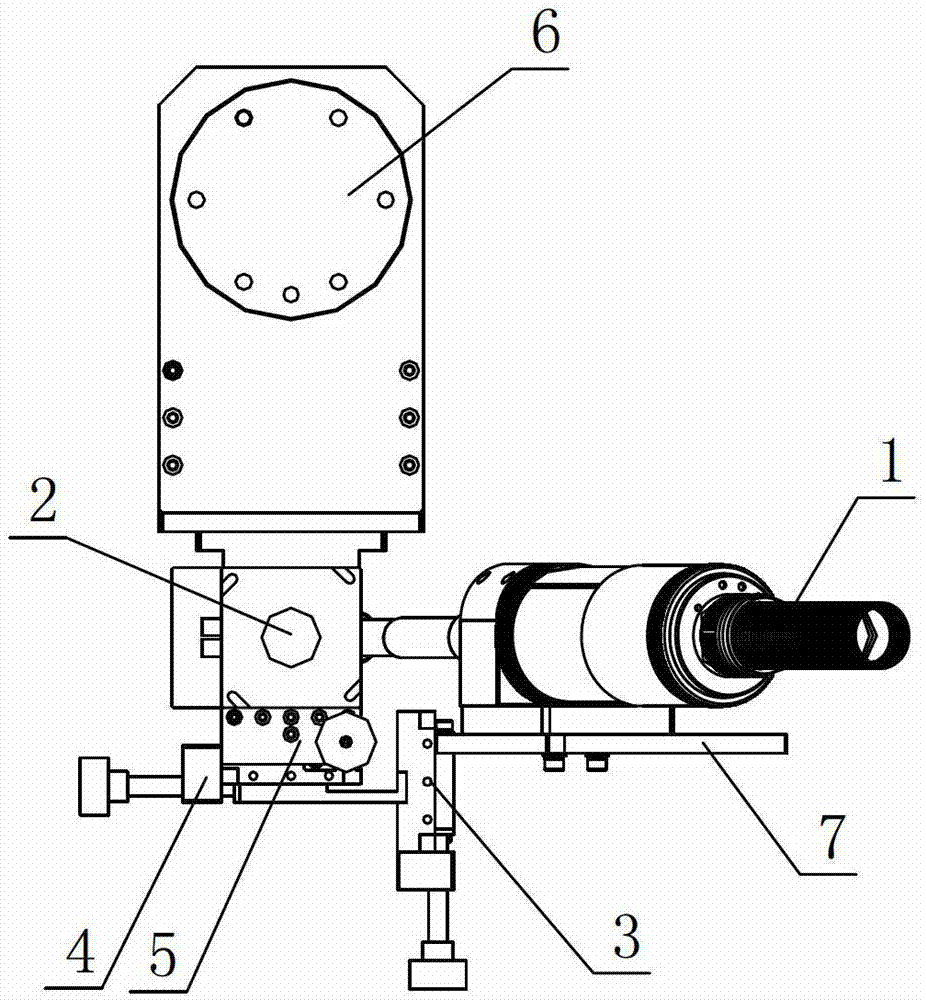

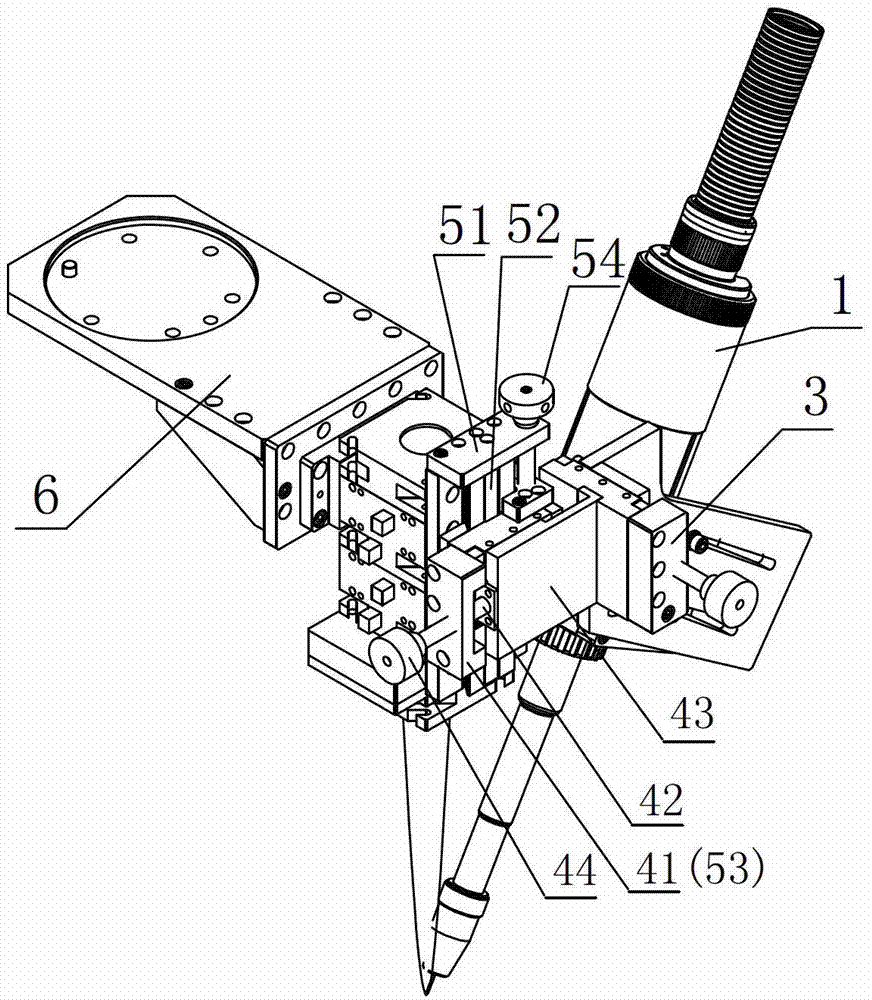

[0021] Such as Figure 1 to Figure 4 , is a structural schematic diagram of an embodiment of a laser-arc hybrid welding head adjustment device according to the present invention, including a laser welding head 2, an arc welding torch 1, an X-axis adjustment mechanism 3, a Y-axis adjustment mechanism 4, a Z-axis adjustment mechanism 5 and a connecting flange 6. The connecting flange 6 is connected with the laser welding head 2, and the angle adjustment plate 7 is connected with the X-axis adjustment mechanism 3. The angle adjustment plate 7 is provided with two concentric arc-shaped slots 8, and the arc slots 8 are respectively set There are screw one 9 and screw two 10, and screw one 9 and screw two 10 are respectively connected with arc welding torch 1, and screw one 9 and screw two 10 are distributed along the central axis of arc welding torch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com